Crystal silicon dislocation detection method and system

A detection method and technology of crystalline silicon, which is applied in the preparation of test samples and optical testing of flaws/defects, etc., can solve the problems of silicon blocks that cannot be used normally, waste of raw materials for tested silicon blocks, and inconvenient operation, etc., to achieve shortening The effect of detection process, low cost and small detection error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

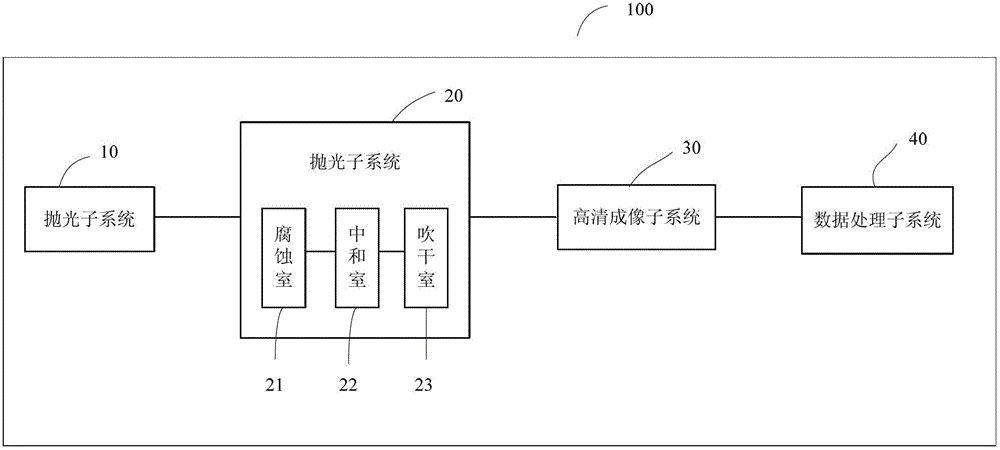

[0045] A method for detecting dislocations in crystalline silicon, comprising the following steps:

[0046] (1) Take a 156mm×156mm×230mm polysilicon block, polish it to a surface roughness value of Ra=0.2, etch the surface of the polished polysilicon block with an etching solution for 5 minutes to show the dislocation or defect of the silicon block, After the corrosion time is up, stop the corrosion with 1% NaOH solution, wash the polysilicon block with water and spray it to dry;

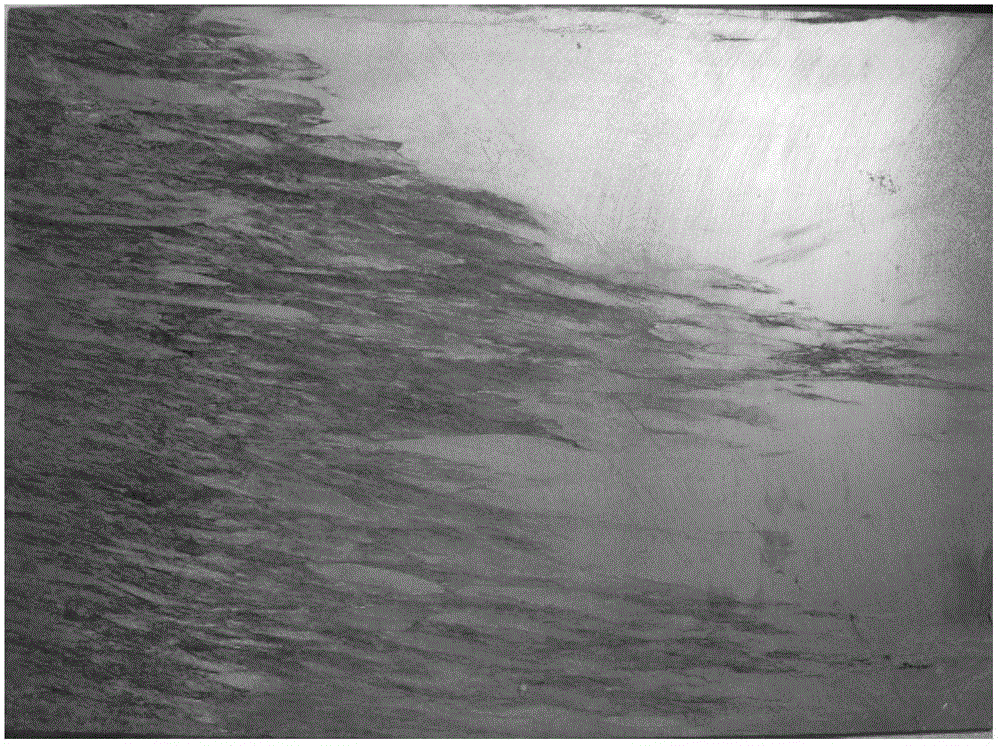

[0047] (2) Using a high-definition imaging system to image the surface dislocation of the obtained silicon block to obtain a corrosion image of the silicon block, so as to obtain the gray pixel ratio of the corrosion pit of the corrosion image according to the X, Y coordinates in the corrosion image and the corresponding pixel information;

[0048] (3) Measure the standard sample and establish the relational formula: take another 156mm×156mm×230mm polysilicon block, polish it to the surface roughnes...

Embodiment 2

[0058] A method for detecting dislocations in crystalline silicon, comprising the following steps:

[0059] (1) Take a 125×125×280mm polysilicon block, polish it to a surface roughness value of Ra=0.2, etch the surface of the polished polysilicon block with an etching solution for 10 minutes to show dislocations or defects of the silicon block, After the corrosion time is up, stop the corrosion with 1% NaOH solution, wash the polysilicon block with water and spray it to dry;

[0060] (2) Using a high-definition imaging system to image the surface dislocation of the obtained silicon block to obtain a corrosion image of the silicon block, so as to obtain the gray pixel ratio of the corrosion pit of the corrosion image according to the X, Y coordinates in the corrosion image and the corresponding pixel information;

[0061] (3) According to the relationship between the gray scale pixel ratio of corrosion pits obtained in Example 1 and the dislocation density value: dislocation de...

Embodiment 3

[0067] A method for detecting dislocations in crystalline silicon, comprising the following steps:

[0068] (1) Take a 125×125×280mm polysilicon block, polish it to a surface roughness of Ra=0.1, etch the surface of the polished polysilicon block with an etching solution for 20 minutes, to show dislocations or defects of the silicon block, After the corrosion time is up, stop the corrosion with 1% NaOH solution, wash the polysilicon block with water and spray it to dry;

[0069] (2) Using a high-definition imaging system to image the surface dislocation of the obtained silicon block to obtain a corrosion image of the silicon block, so as to obtain the gray pixel ratio of the corrosion pit of the corrosion image according to the X, Y coordinates in the corrosion image and the corresponding pixel information;

[0070] (3) According to the relationship between the gray scale pixel ratio of corrosion pits obtained in Example 1 and the dislocation density value: dislocation density...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com