Method for predicting breaking rate of food strip made by food powder

A technology of broken bar rate and food, applied in the direction of material analysis using radiation diffraction, etc., can solve the problems of meaninglessness, deviation of prediction results, unsuitable bar broken rate, etc., achieve high accuracy, short measurement process, and easy to be widely used The effect of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

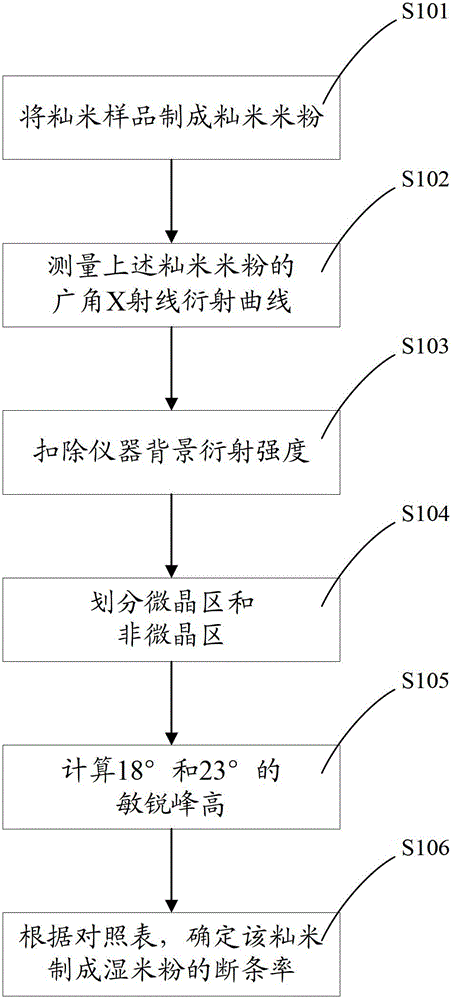

[0028] The first embodiment of the present invention provides a method for predicting the broken bar rate of wet rice flour prepared from early-indica rice, and provides a comparison between the predicted result of the method and the broken bar rate of an actual sample.

[0029] The broken bar rate refers to the bar broken rate determined according to the method specified in SN / T 0395-95 "Export Rice Flour Inspection Regulations".

[0030] In step S101, the early-made indica rice sample is made into powdered indica rice flour.

[0031] The samples of early-made indica rice to be processed are pulverized by a pulverizer (specifically, the FSJ-1 grain test pulverizer), and then passed through an 80-mesh sieve; and then ground by a cyclone pulverizer (FOSETECATOR) to ensure that 99.6% of the obtained rice flour can be Cross 100 mesh sieves to obtain powdered indica rice flour.

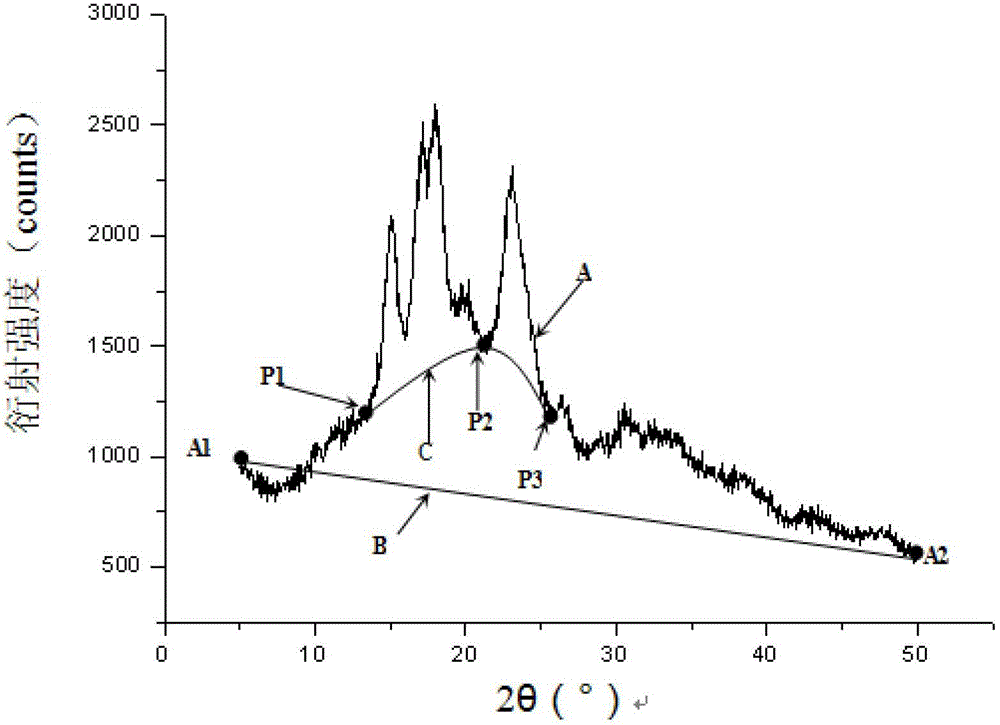

[0032] Step S102, measuring the wide-angle X-ray diffraction curve of the above-mentioned indica rice...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com