Novel vision system for photoetching equipment

A vision system and lithography equipment technology, applied in the field of new vision systems, can solve problems such as the failure to select the spectral characteristics, shape and background of the observed objects, and the poor use effect of the vision system, so as to achieve good observation and recognition of objects. , Improve the effect of alignment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in detail below in conjunction with accompanying drawing:

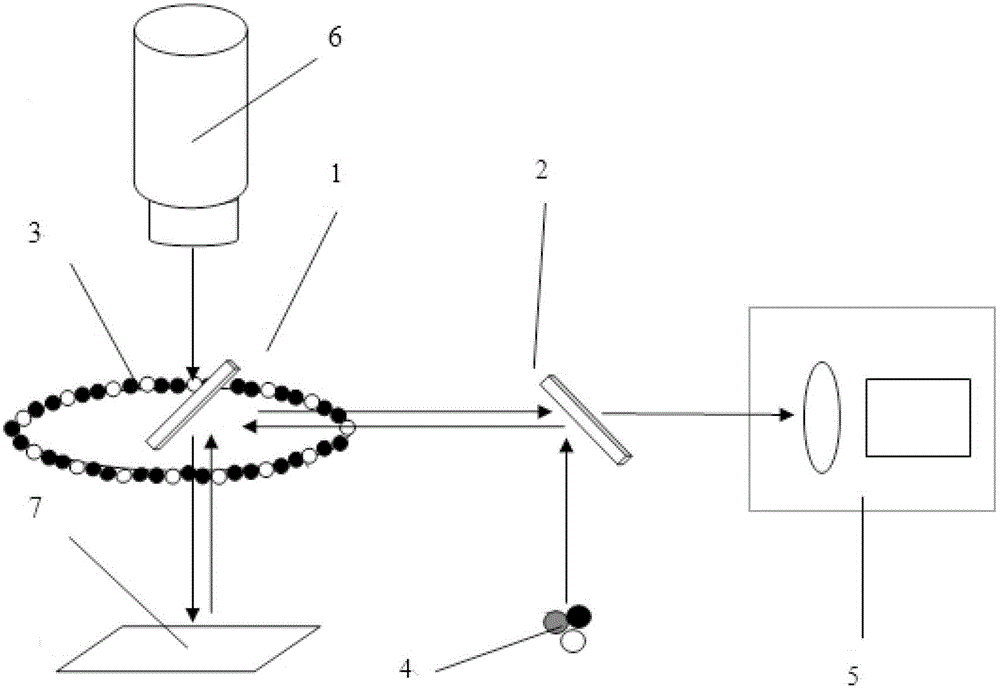

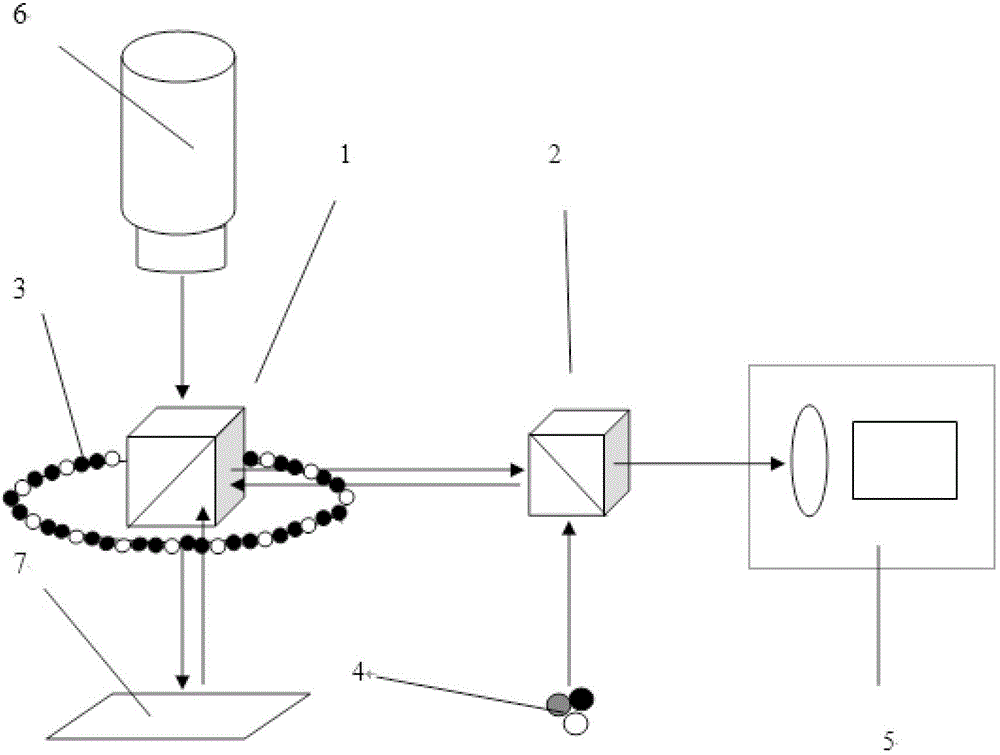

[0023] As shown in the figure, a new type of vision system for lithography equipment includes R, G, B three-color LED light sources and light sensors. In addition, it is also equipped to refract R, G, B three-color LED light sources to the light sensor. spectroscope.

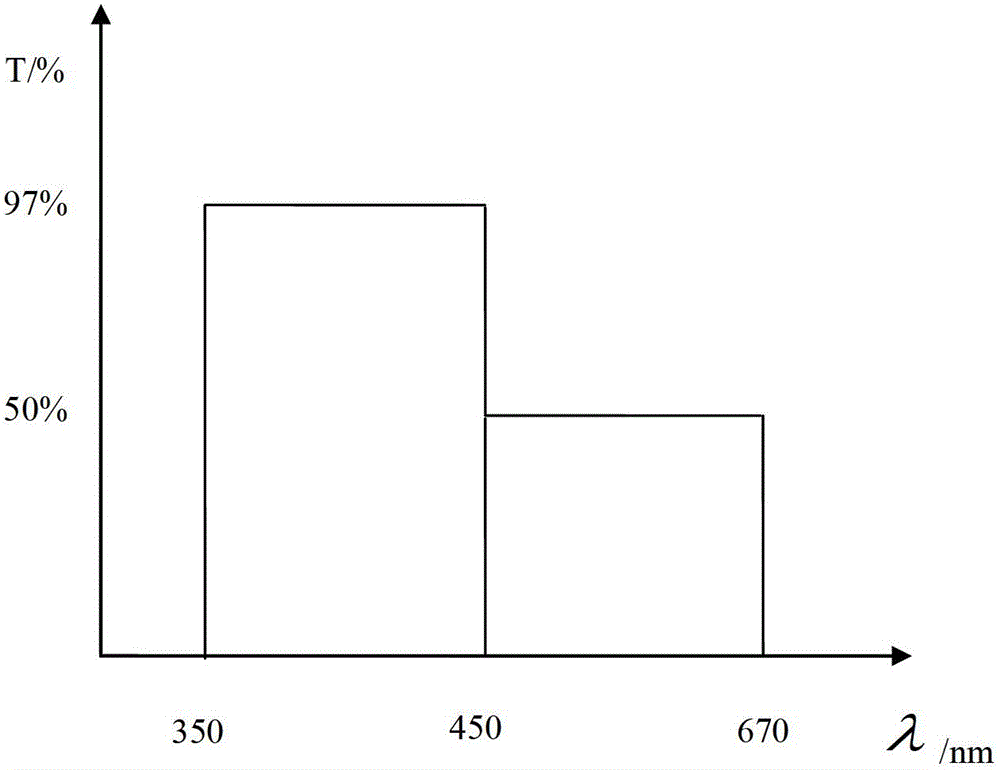

[0024] Specifically, the beam splitter is one or more beam splitting prisms or beam splitting mirrors. The R, G, B three-color LED light sources are single or multiple sets of R, G, B three-color LED light sources. The three-color light emitted by the R, G, and B three-color LED light sources is reflected by the object, refracted by the beam splitter, and then reaches the light sensor to form a visible image. When there is one beam splitter, the R, G, and B three-color LED light sources are a single group of three-color LED light sources. When there are multiple beam splitters, the number of groups of the R, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com