Molding method for panel of injection molded part and air-conditioner display apparatus

A technology for display devices and injection molded parts, applied in heating methods, space heating and ventilation details, household heating, etc., can solve problems such as rough surfaces, poor dimensions, and poor display effects, so as to improve product gloss and shorten molding Cycle, the effect of accelerating the curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

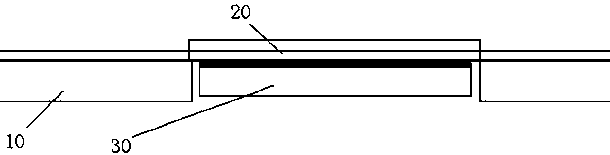

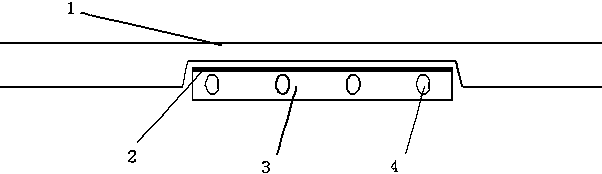

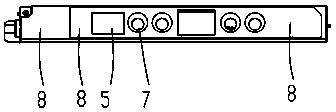

Image

Examples

Embodiment Construction

[0033] The molding method of the injection molded part panel of the present invention is characterized in that it comprises the following steps:

[0034] (1) Pass high-pressure water into the mold before injection (such as the temperature range of 170-180°C), so that the temperature of the mold reaches the viscous flow temperature (such as 110-125°C) that exceeds the thermal deformation of the resin to reduce the temperature of the molten resin. Viscosity, improving the fluidity of molten resin, reducing plastic pressure, reducing product deformation, achieving good welding, while rapid heating and rapid cooling improves the crystallization state of plastics and improves the surface gloss of products;

[0035] (2) Inject molten resin into the mold, so that a molded product with no sink line and good surface quality will be formed;

[0036] (3) Use cooling water to quickly drop the mold temperature below the thermal deformation temperature of the resin (such as 50-60°C).

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com