Strip-shaped body cutting position adjustment method and system for cutting apparatus

An adjustment method and technology of strips, which are applied to general parts of printing machinery, sending objects, transportation and packaging, etc., can solve problems such as a large amount of waste paper, and achieve the effect of suppressing the generation of waste paper and shortening the cutting time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Next, the method and device for adjusting the cutting position of the strip-shaped piece of the cutting device of the present invention will be described in detail by using the embodiments and referring to the accompanying drawings.

[0058] (Example)

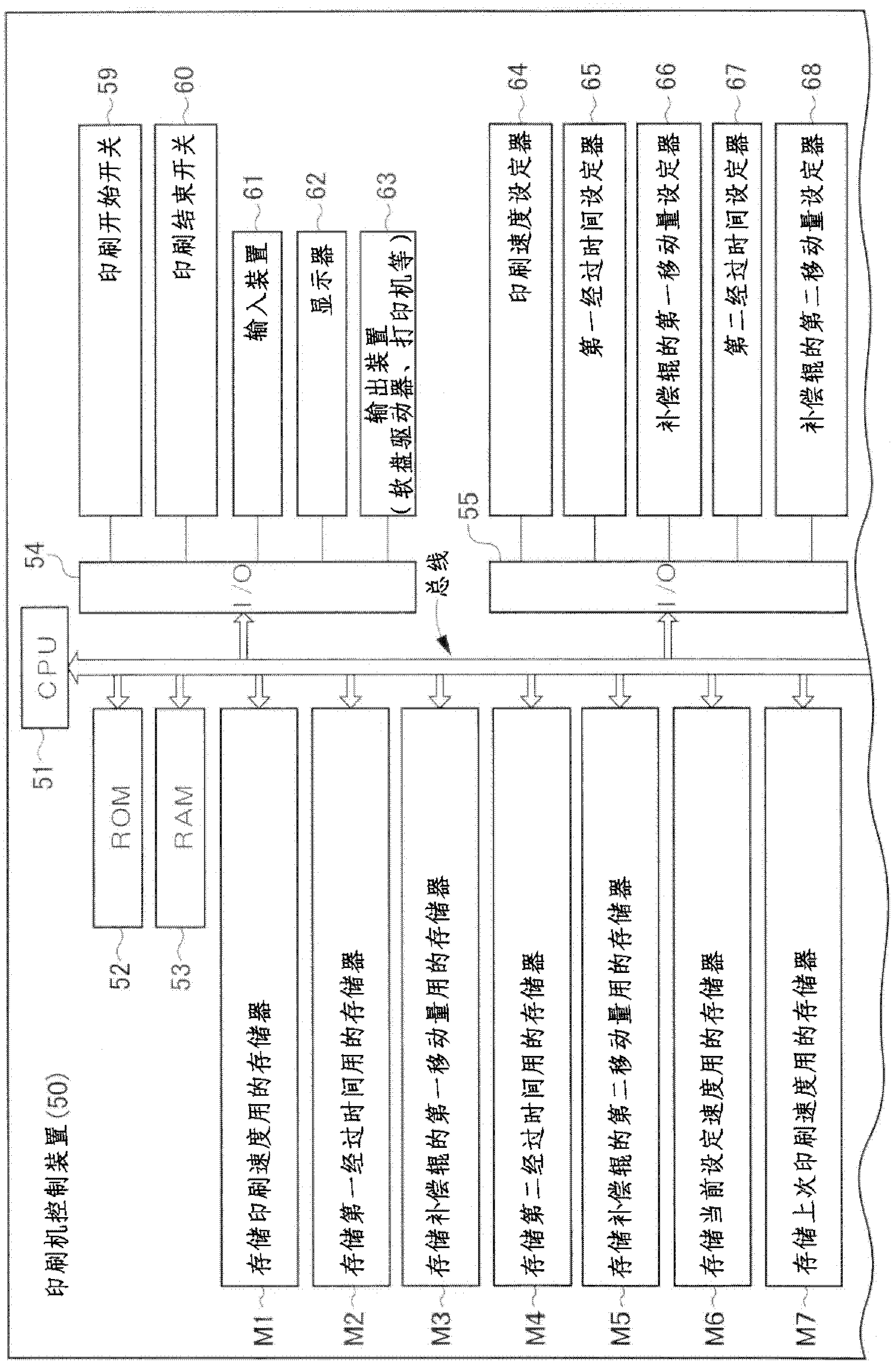

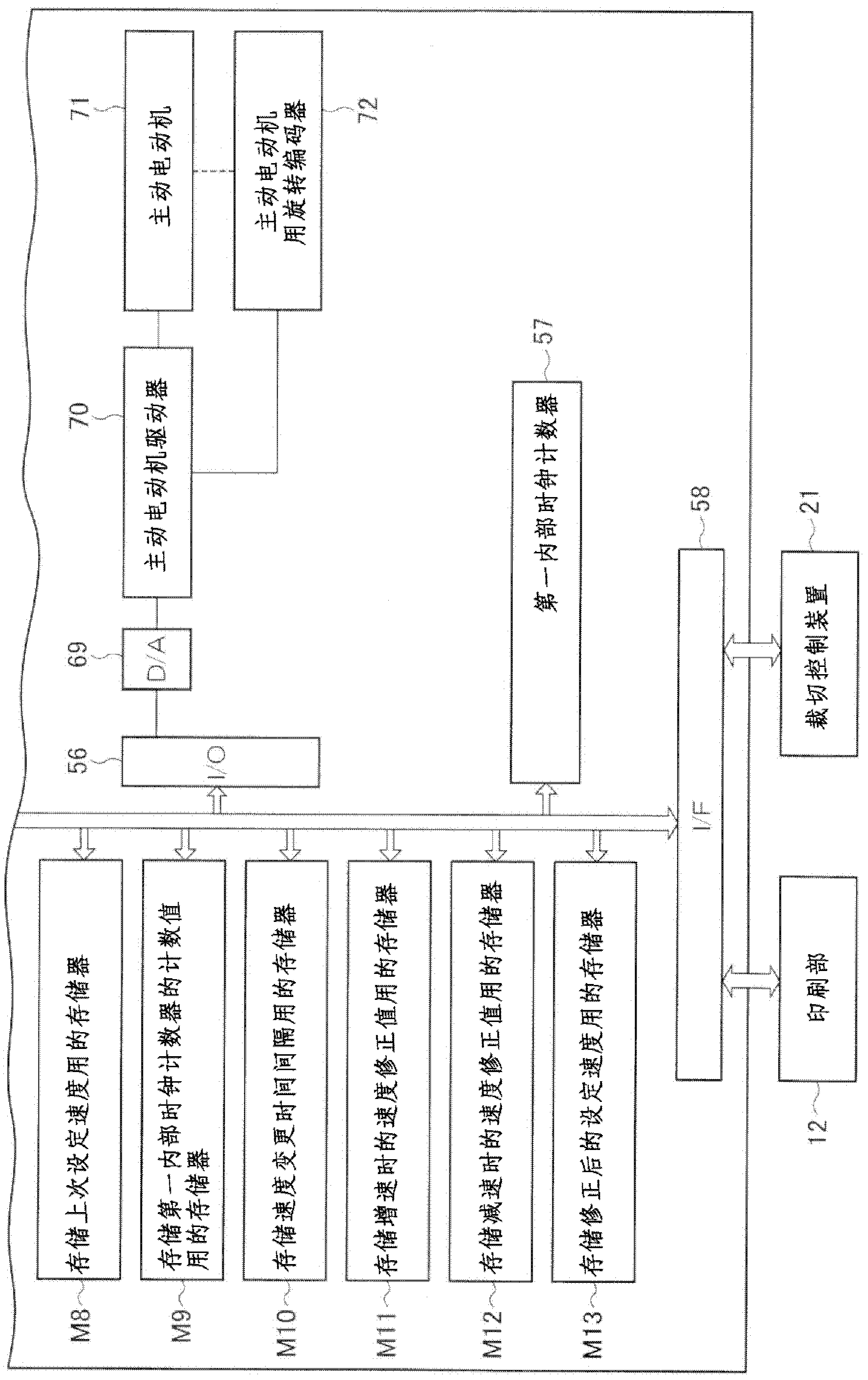

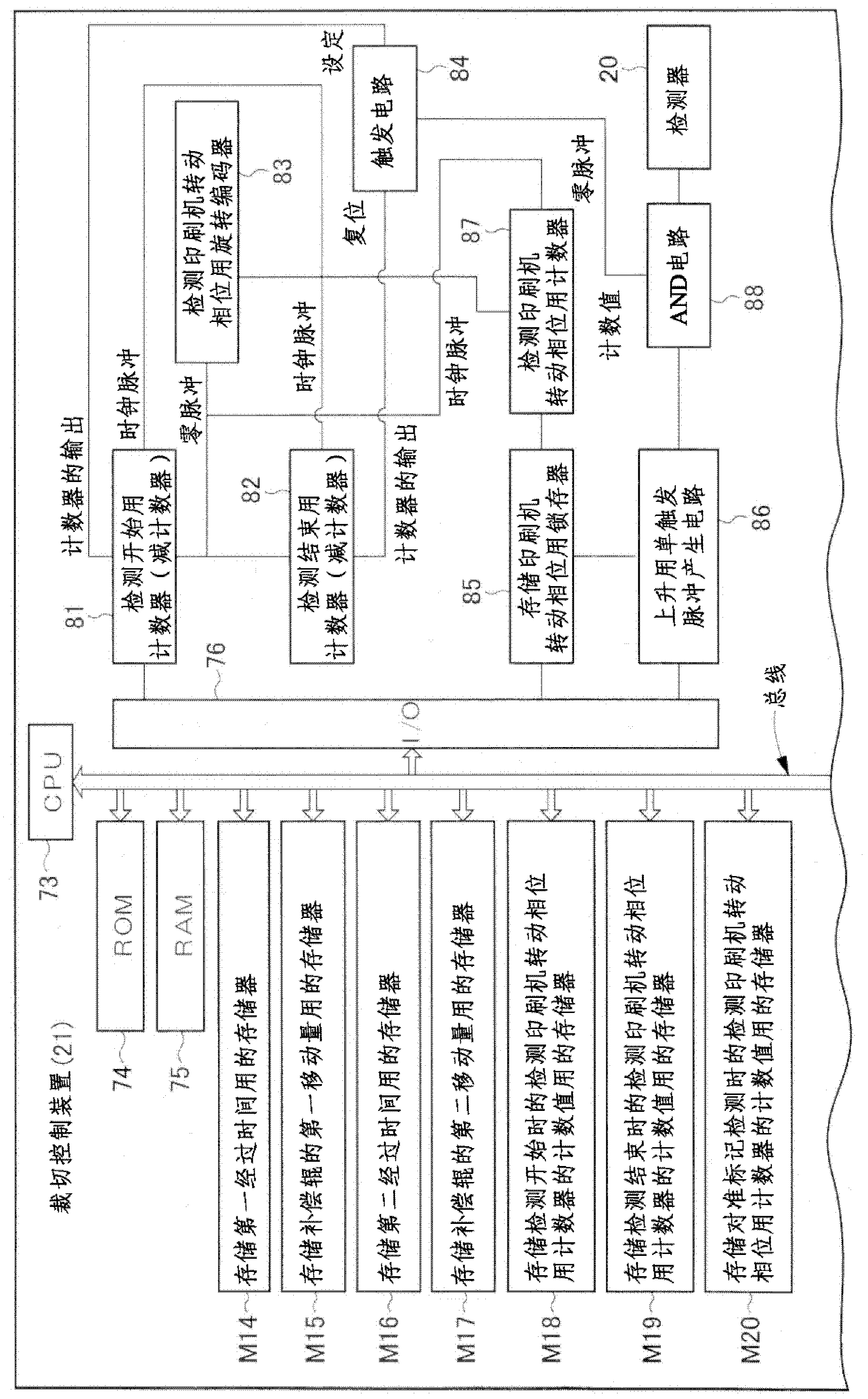

[0059] Figure 1A and Figure 1B is a block diagram showing a printing press control device according to an embodiment of the present invention, Figure 2A and Figure 2B is the block diagram of the cutting control device, Figure 3A to Figure 3E It is the flow chart of the operation of the printing machine control device, Figure 4A to Figure 4E , Figure 5A and Figure 5B , Figure 6A to Figure 6D , Figure 7A and Figure 7B It is the action flowchart of the cutting control device, Figure 8 It is a three-dimensional view of the brief structure of a web rotary press, Figure 9 It is a graph showing the operating position of the comparative compensation roller.

[0060] Such as Figure 8 As shown, the web ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com