Hydraulically-controlled electronic parking executing mechanism

A technology of electronic parking and actuators, which is applied to vehicle components, brakes, transportation and packaging, etc., can solve the problems of intermittent power transmission, large wear between gears, and large limitations, and achieve continuous power transmission, fewer moving parts, and Applicable to a wide range of car models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

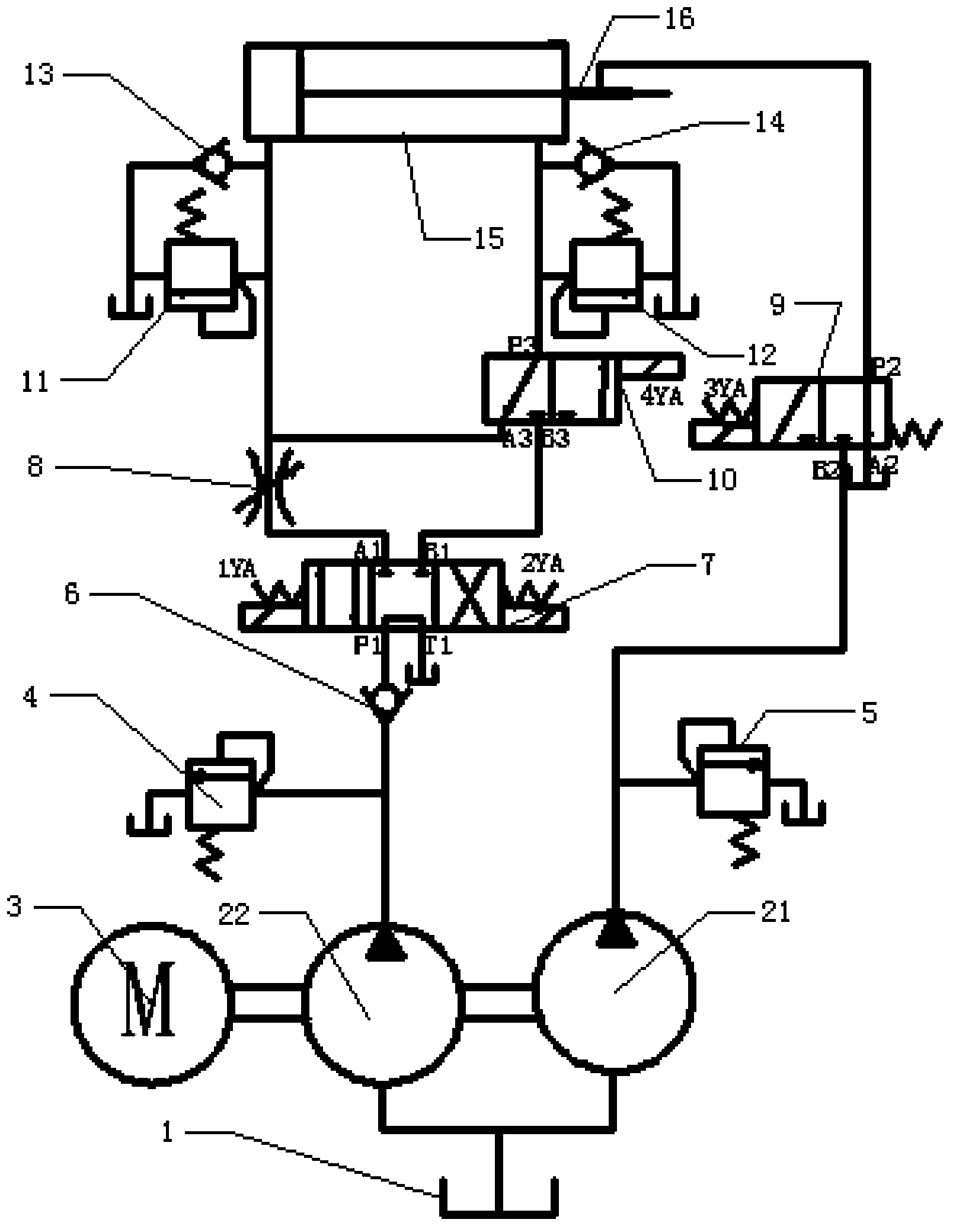

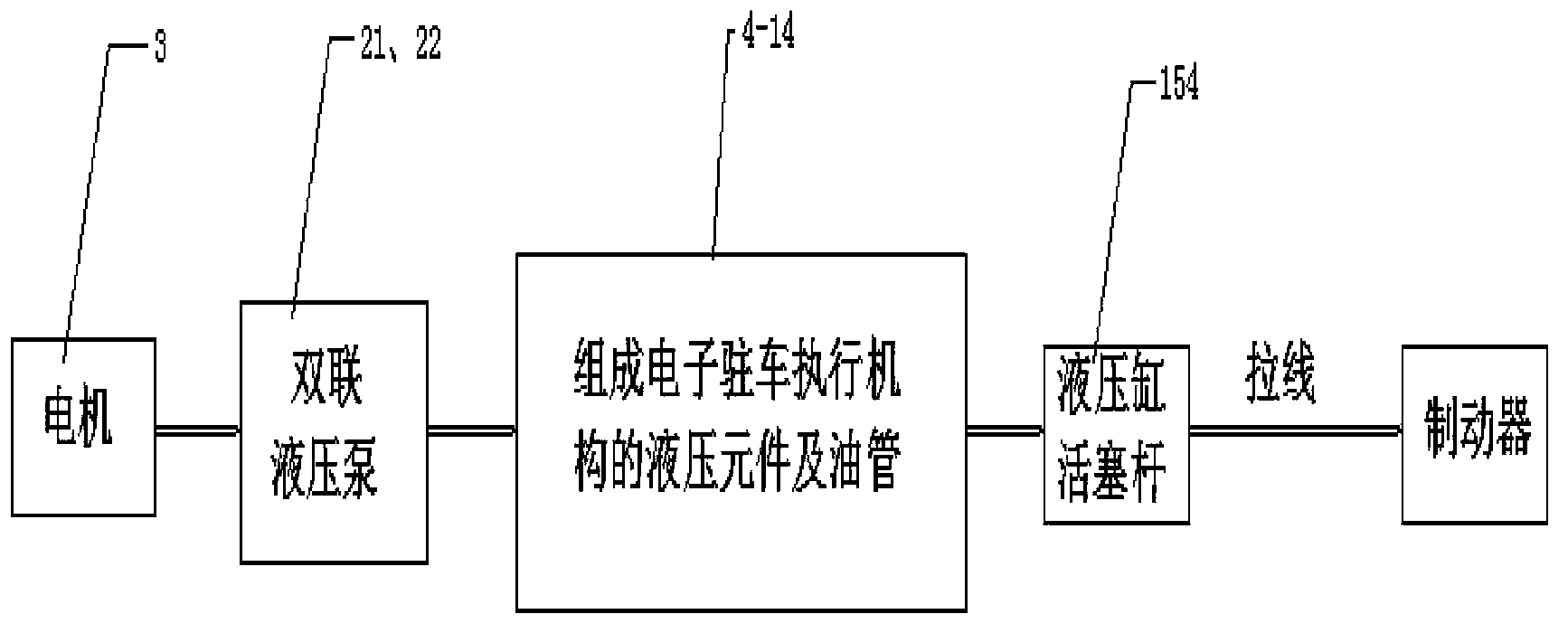

[0022] The general idea of the present invention is as image 3 As shown: the motor 3 controls the double hydraulic pump (high pressure pump 21 and low pressure pump 22) to supply oil to the system, and drives the hydraulic cylinder piston rod 154 through the hydraulic components 4-14 and oil pipes that form the electronic parking actuator, and the piston rod 154 is driven by the piston rod 154 drives the stay wire, controls the brake, and realizes braking.

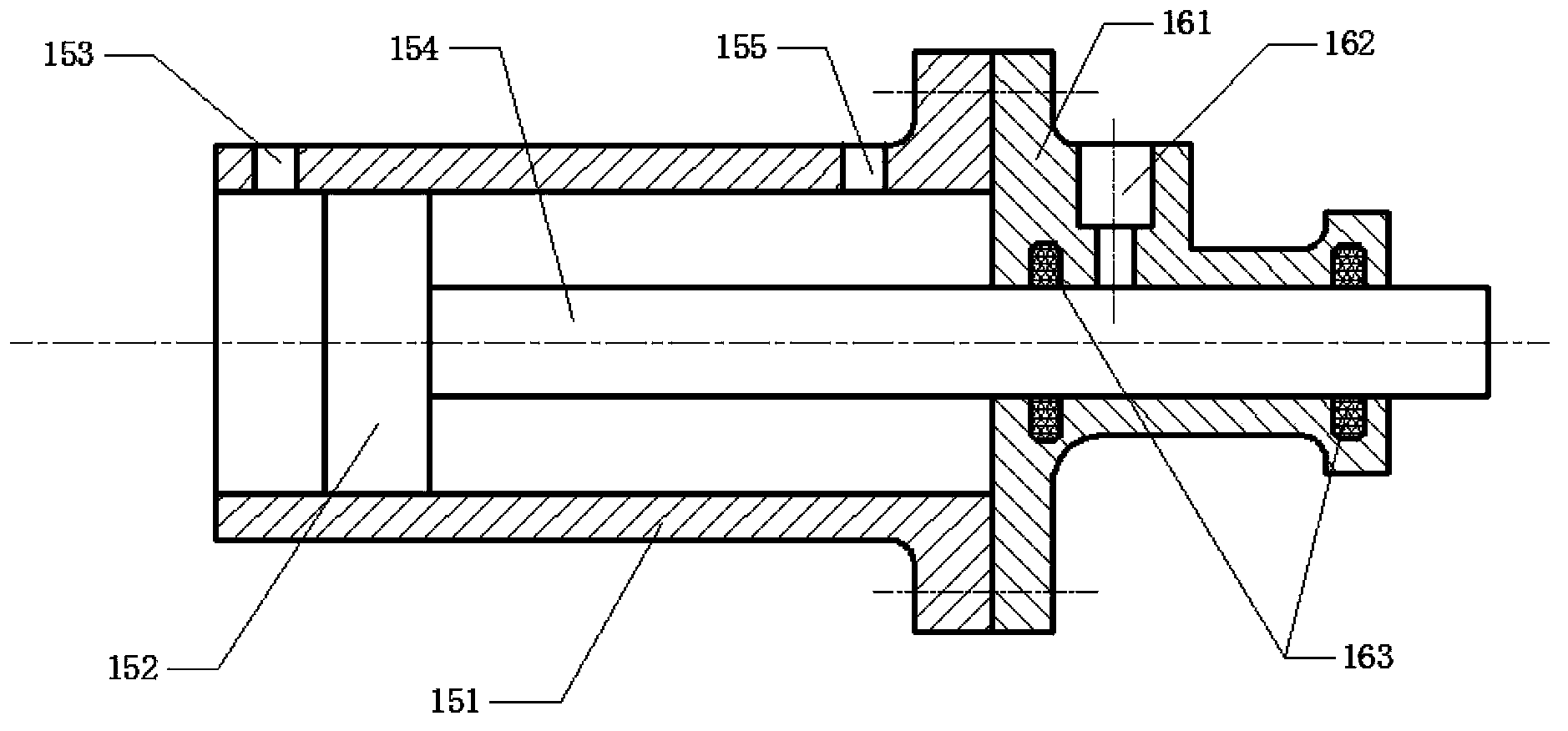

[0023] Such as figure 1 , figure 2 As shown, the hydraulic control electronic parking actuator of the present invention includes a high-pressure pump 21 and a low-pressure pump 22 driven by the motor 3 in double connection, and is used to control the hydraulic cylinder 15 of the brake. The hydraulic cylinder 15 includes a cylinder body 151 located in the cylinder The piston 152 in the body 151, the piston rod 154 connected to one end of the piston 152, and the locking device 16 that is used to lock the piston rod 154...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com