Zr-Ti-based microwave dielectric ceramic material and preparation method thereof

A microwave dielectric ceramic, zr-ti technology, applied in ceramics, inorganic insulators and other directions, to achieve the effect of great popularization and practical value and simple sintering conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

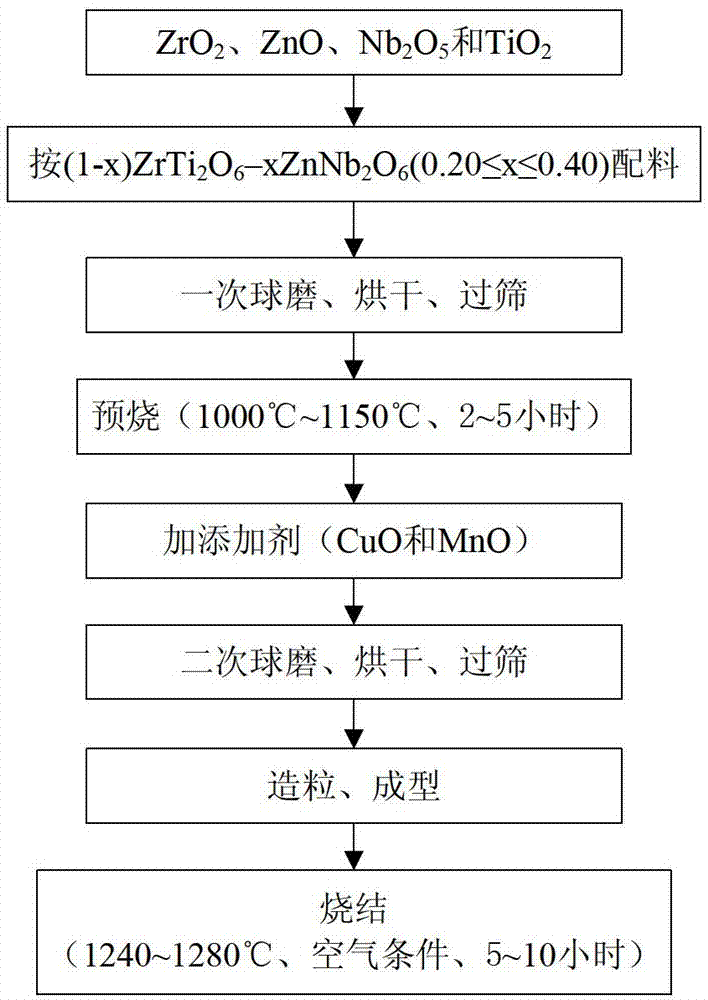

[0024] The concrete implementation steps that make these embodiment microwave dielectric ceramics are as follows:

[0025] (1) Select ZrO with purity ≥99% 2 , ZnO, Nb 2 o 5 and TiO 2 As a raw material, according to the composition formula (1-x) ZrTi 2 o 6 -xZnNb 2 o 6 (0.20≤x≤0.40) molar ratio for batching, the specific formula is shown in Table 1;

[0026] (2) Put the above-mentioned prepared materials into the nylon ball mill tank, use zirconium balls as the balls and deionized water as the ball milling medium, and conduct a ball mill for 10-20 hours; Dry and pass through a 60-mesh sieve;

[0027] (3) Pre-calcining the above-mentioned primary ball mill material passed through a 60-mesh sieve at a temperature of 1000°C to 1150°C for 2 to 5 hours to obtain a pre-fired material;

[0028] (4) Add additives to the calcined material, that is, CuO equivalent to y wt% of the mass of the base material after calcining and MnO of z wt%, wherein 0.50≤y≤2.50, 0.12≤z≤0.90, the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com