Non-allergenic fully-degradable medical and hygienic non-woven material capable of adjusting moisture

A medical and hygienic, fully degradable technology, applied in the field of medical and hygienic non-woven materials, can solve the problems of different performance consumer groups and final application fields, complex production processes, etc., and achieve good non-allergenic, bacteriostatic and deodorizing functions. , good strength, good antibacterial and deodorant effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

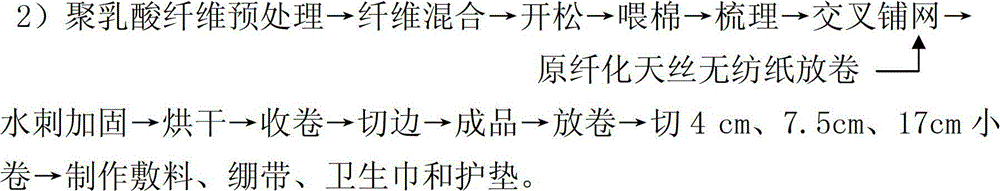

Embodiment 1

[0031] The length of tencel fiber is 5mm, the fineness is 3.3dtex, the concentration of the web-forming slurry is controlled to be 0.04%, the beating time is 65 minutes, the degree of beating is controlled to be 50°SR, and the degree of fibrillation of the tencel fiber reaches 60%. The weight of non-woven paper is 9 grams per square meter, and the tensile strength is 0.2KN / m. Select the polylactic acid fiber with a length of 38mm and a fineness of 2.2dtex. First, the polylactic acid fiber is pretreated. The pretreatment process is: spray the polylactic acid fiber with 8% of the total fiber weight of the antistatic agent mixture, and the antistatic agent mixture is determined by mass. It is composed of 3% antistatic agent and 97% water by mass, and then covered with plastic cloth and stuffed for 28 hours for soft moisture absorption treatment, so that the moisture regain of polylactic acid fiber reaches 8%. Then the polylactic acid fiber is mixed and opened, fed and carded, and c...

Embodiment 2

[0037] The length of tencel fibers is selected to be 3mm, the fineness is 2.2dtex, the concentration of the web-forming slurry is controlled to be 0.03%, the beating time is 70 minutes, the beating degree is controlled to be 55°SR, and the degree of fibrillation of the tencel fibers reaches 65%. The non-woven paper has a weight of 15 grams per square meter and a tensile strength of 0.35KN / m. Select the polylactic acid fiber with a length of 38mm and a fineness of 1.67dtex. First, the polylactic acid fiber is pretreated. The pretreatment process is: spray the polylactic acid fiber with 5% of the total fiber weight of the antistatic agent mixture, and the antistatic agent mixture is determined by mass. It is composed of 2% antistatic agent and 98% water by mass, and then covered with plastic cloth and stuffed for 24 hours for soft moisture absorption treatment, so that the moisture regain of polylactic acid fiber reaches 5%. Then, the polylactic acid fiber is mixed and loosened,...

Embodiment 3

[0043] The length of tencel fiber is 6mm, the fineness is 3.3dtex, the concentration of web-forming slurry is controlled to be 0.05%, the beating time is 90 minutes, the degree of beating is controlled to be 65°SR, and the degree of fibrillation of tencel fiber reaches 55%. The non-woven paper has a weight of 18 grams per square meter and a tensile strength of 0.48KN / m. Select the polylactic acid fiber with a length of 51mm and a fineness of 3.3dtex. First, the polylactic acid fiber is pretreated. The pretreatment process is: spray the polylactic acid fiber with 5% of the total fiber weight of the antistatic agent mixture, and the antistatic agent mixture is determined by mass. It is composed of 2% antistatic agent and 98% water by mass, and then covered with plastic cloth and stuffed for 24 hours for soft moisture absorption treatment, so that the moisture regain of polylactic acid fiber reaches 8%. Then, the polylactic acid fiber is mixed and loosened, fed and carded, and cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com