Magnetorheological fluid continuously variable transmission

A technology of continuously variable transmission and magneto-rheological fluid, which is applied to friction transmission devices, belts/chains/gears, mechanical equipment, etc., and can solve problems such as the inability to control the speed of the transmission shaft, the inability to realize stepless speed change, and the large volume of circuit settings, etc. problem, to achieve the effect of good speed control, simple structure and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below with reference to the accompanying drawings.

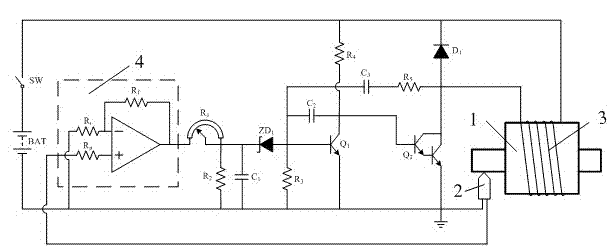

[0010] like figure 1 As shown, the present invention includes a magnetorheological fluid transmission device 1 and a rotational speed adjusting circuit, characterized in that, the rotational speed adjusting circuit includes a rotational speed sensor 2, an excitation coil 3, a voltage amplifier 4, a speed regulating resistor R 1 , divider resistor R 2 , current limiting resistor R 3 , resistance R 4 , resistance R 5 , filter capacitor C 1 , negative feedback capacitor C 2 , Positive feedback capacitor C 3 , transistor Q 1 , Darlington transistor Q 2 , freewheeling diode D 1 , Zener diode ZD 1 , switch SW and DC power supply BAT, the speed sensor 2 and the excitation coil 3 are arranged outside the magnetorheological fluid transmission device 1, one end of the speed sensor 2 is grounded, and the other end is connected to the positive-phase signal input end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com