LED (light-emitting diode) backlight module

A technology of backlight module and LED light bar, which is applied in the direction of optics, light guide, light source, etc., can solve the problems of damage to the light guide plate, affect the backlight efficiency, and increase the distance between the light guide plate and LED, so as to ensure the coupling distance and improve the Effect of coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

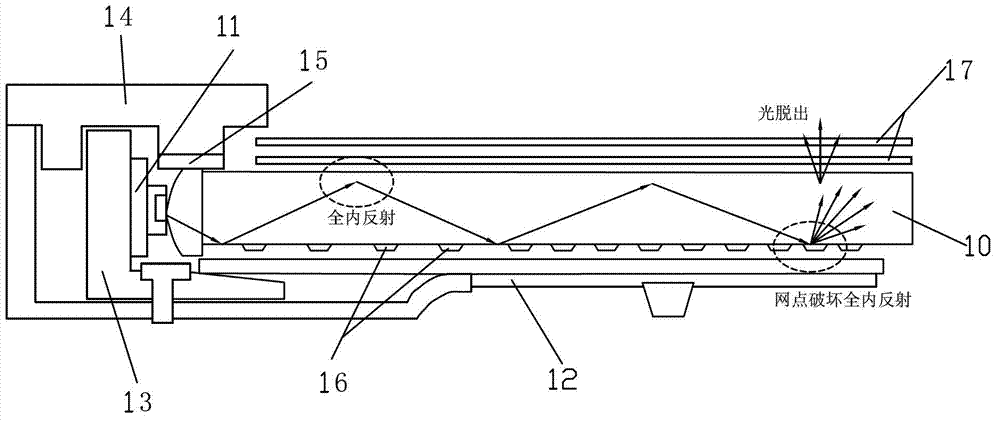

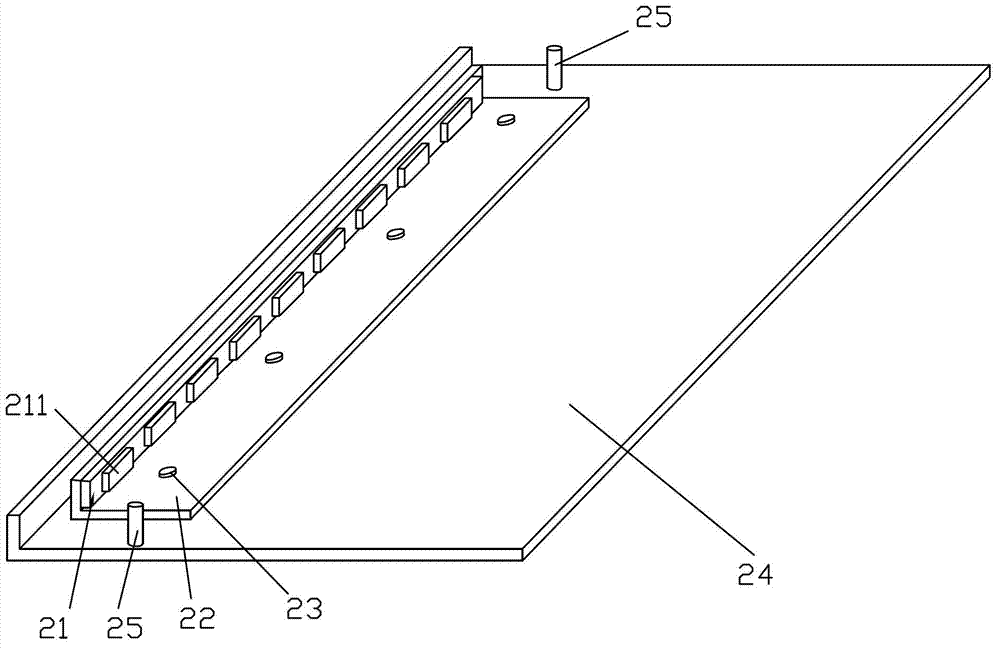

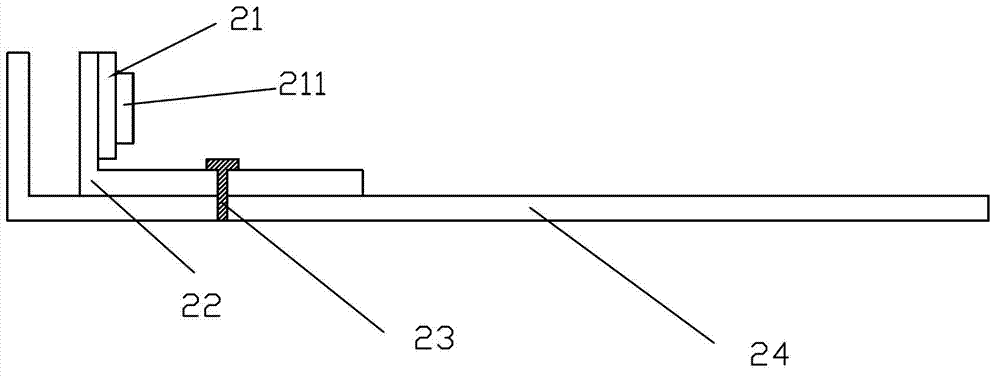

[0036] see Figure 6 to Figure 10 , Figure 6 It is a three-dimensional schematic diagram of a backplane of a preferred embodiment of the LED backlight module of the present invention; Figure 7 for Figure 6 Top view of the mid-backplane; Figure 8 It is a three-dimensional schematic diagram after removing the light guide plate for a preferred embodiment of the LED backlight module of the present invention; Figure 9 It is a top view of the light guide plate of a preferred embodiment of the LED backlight module of the present invention; Figure 10 It is an assembly diagram of a preferred embodiment of the LED backlight module of the present invention.

[0037] The LED backlight module of the present invention mainly includes a light guide plate 30, an LED light bar 31, a back plate 32, and a heat sink 33. The LED light bar 31 is fixed on the heat sink 33 adjacent to the light incident side of the light guide plate 30, and There is an upwardly extending light guide plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com