Serial air conditioner and temperature regulating box all-in-one machine and operation control method thereof

A temperature control box and tandem technology, which is applied in the field of serial air conditioner and temperature control box integrated machine and its operation control, can solve the problems of backflow, high cost, and the inability of refrigerant to flow out from the outlet, so as to achieve convenient use, space saving and The effect of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

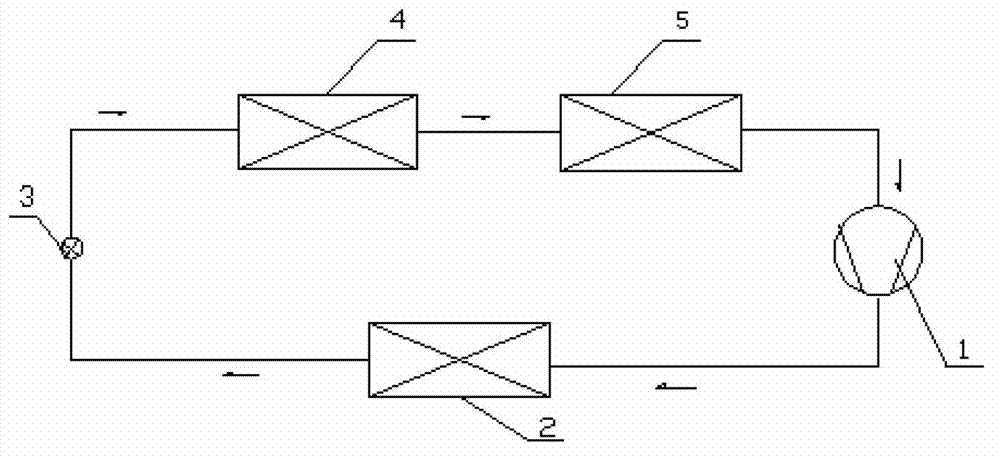

[0030] as attached figure 1 As shown, the series air conditioner and thermostat box integrated system includes a compressor 1, an indoor air conditioner heat exchanger 5, an indoor thermostat box heat exchanger 4, a throttling mechanism 3 and an outdoor heat exchanger 2. A circulation pipeline system, and the heat exchanger 4 of the indoor thermostat box and the heat exchanger 5 of the indoor air conditioner are sequentially connected in series. That is, the refrigerant enters the outdoor heat exchanger 2 after being compressed by the compressor 1 to exchange heat with the outdoor environment. Heat exchange to achieve the purpose of cooling the thermostat box, and then enter the indoor air conditioner heat exchanger 5 to exchange heat with the indoor environment to achieve the effect of adjusting the room temperature, and finally the low-pressure gaseous refrigerant returns to the air inlet of the compressor 1, and thus circulates. The cooling function of the thermostat box a...

Embodiment 2

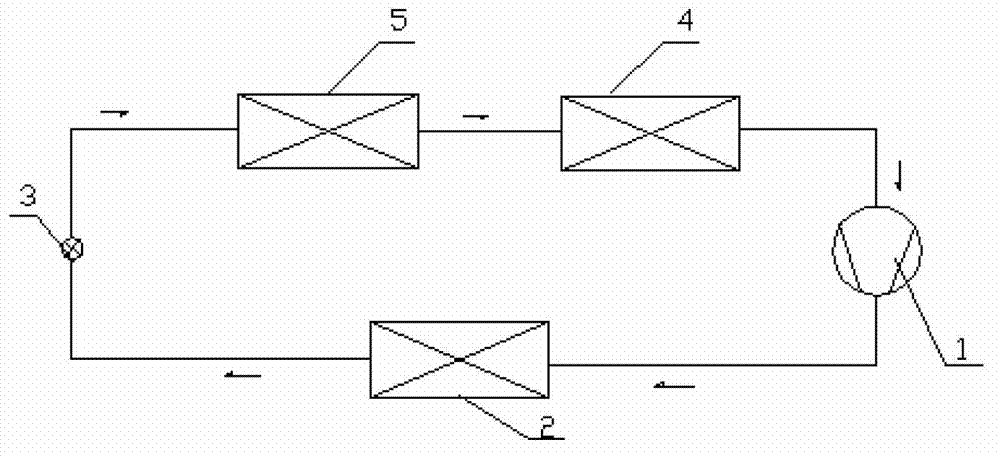

[0032] as attached figure 2 As shown, the difference from Embodiment 1 is that the positions of the indoor air conditioner heat exchanger 5 and the indoor thermostat heat exchanger 4 have been exchanged. That is, the refrigerant is compressed by the compressor 1 and then enters the outdoor heat exchanger 2 to exchange heat with the outdoor environment. room temperature, and then enter the indoor thermostat box heat exchanger 4 to exchange heat with the thermostat space to achieve the purpose of cooling the thermostat box, and finally the low-pressure gaseous refrigerant returns to the air inlet of compressor 1, and thus circulates.

Embodiment 3

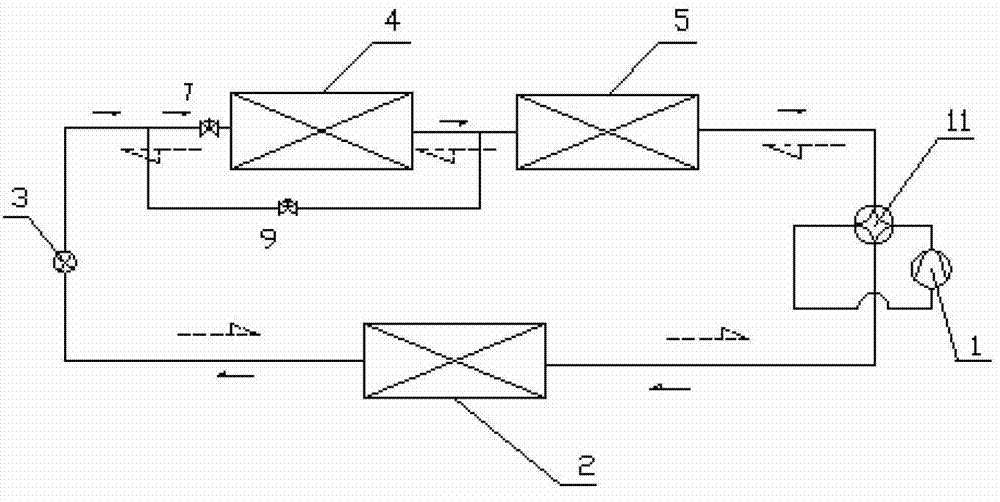

[0034] as attached image 3 As shown, the inlet and outlet of the compressor are respectively connected to the four-way valve 11 to form a refrigeration heat pump system, which can realize different functions of the air conditioner and the thermostat box according to user needs. The solid line arrow shows the cycle of air-conditioning refrigeration and thermostat refrigeration, and the dotted arrow shows the cycle of air conditioning heating and thermostat heating. A first control valve 7 is arranged on the pipeline between the outlet of the electronic expansion valve 3 and the part between the indoor air conditioner heat exchanger 5 and the indoor thermostat heat exchanger 4 . The front of the front of the electronic expansion valve 3 is provided with a bypass pipeline between the outlet of the electronic expansion valve 3 and the heat exchanger 5 of the indoor air conditioner and the heat exchanger 4 of the indoor thermostat box, and a first bypass valve 9 is arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com