Hot air furnace pipe for cupola furnace

A technology of hot blast stoves and cupolas, applied in the improvement of hot blast stoves, in the field of cupola hot blast stoves, it can solve the problems that are not conducive to the full utilization of the heat of the stove, short heat transfer path, short service life, etc., and achieve obvious energy saving effects , service life and heat exchange efficiency improvement, the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

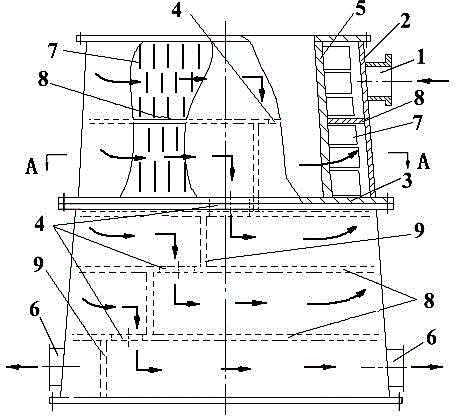

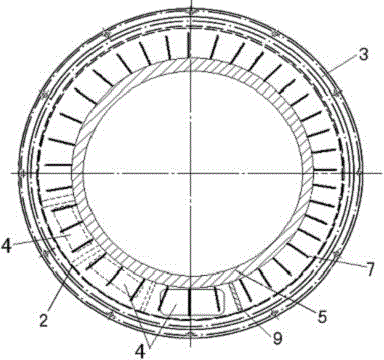

[0012] The present invention will be further described below in conjunction with drawings and embodiments. see figure 1 with figure 2 , a cupola hot-blast furnace, which is divided into an upper furnace furnace and a lower furnace furnace, the upper furnace furnace and the lower furnace furnace are both composed of an outer cylinder 2 and an inner cylinder 5, and the joints of the end faces are connected as a whole by a flange plate 3, An air inlet is provided on the top of the upper furnace outer cylinder 2, an air outlet 6 is provided on the bottom of the lower furnace outer cylinder 2, and a cooling fin 7 is provided on the outer wall of the inner cylinder 5. It is characterized in that: the inner cylinder 5 is an integral steel casting with a flange 3, the outer cylinder 2 wraps the inner cylinder 5, and an annular cavity is formed between the outer wall of the inner cylinder 5 and the inner wall of the outer cylinder 2, and the horizontal direction in the annular cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com