Measuring device and measuring method for straight cone gear pitch cone angle

A technology of bevel gears and measuring devices, applied in angle/taper measurement, etc., can solve problems affecting gear interchangeability, difficulty in accurately measuring the actual angle of straight bevel gear pitch cone angle, direct measurement and detection, which troubles engineers and technicians, etc. problem, to achieve the effect of verifying machining accuracy, low manufacturing cost, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

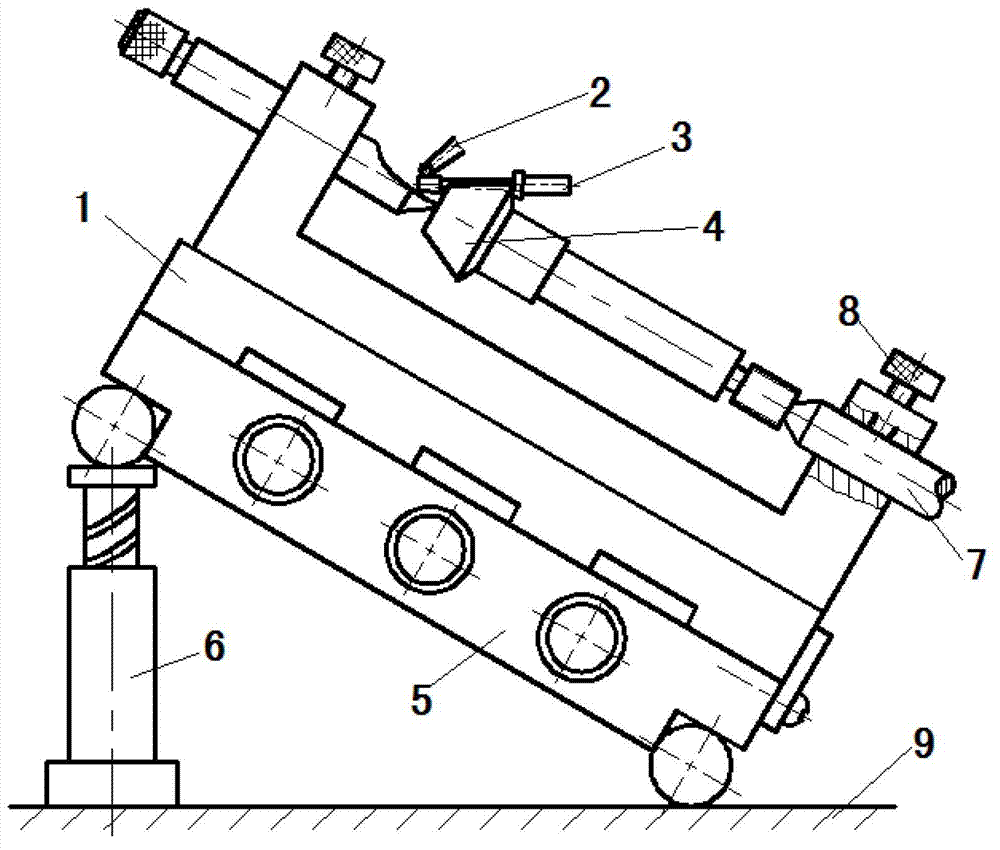

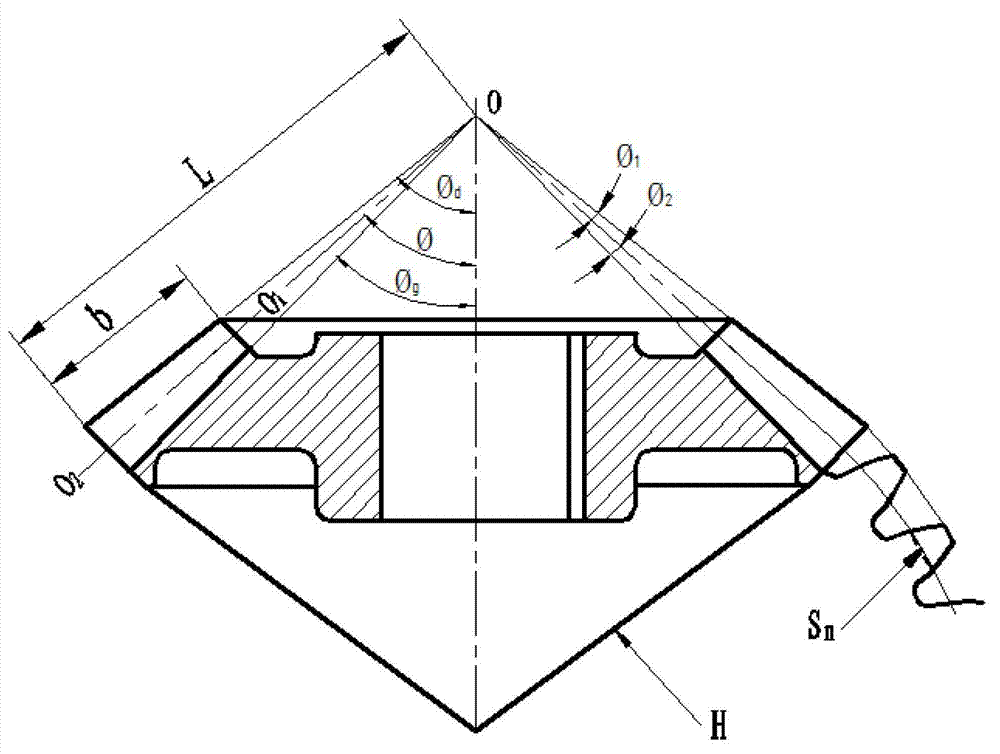

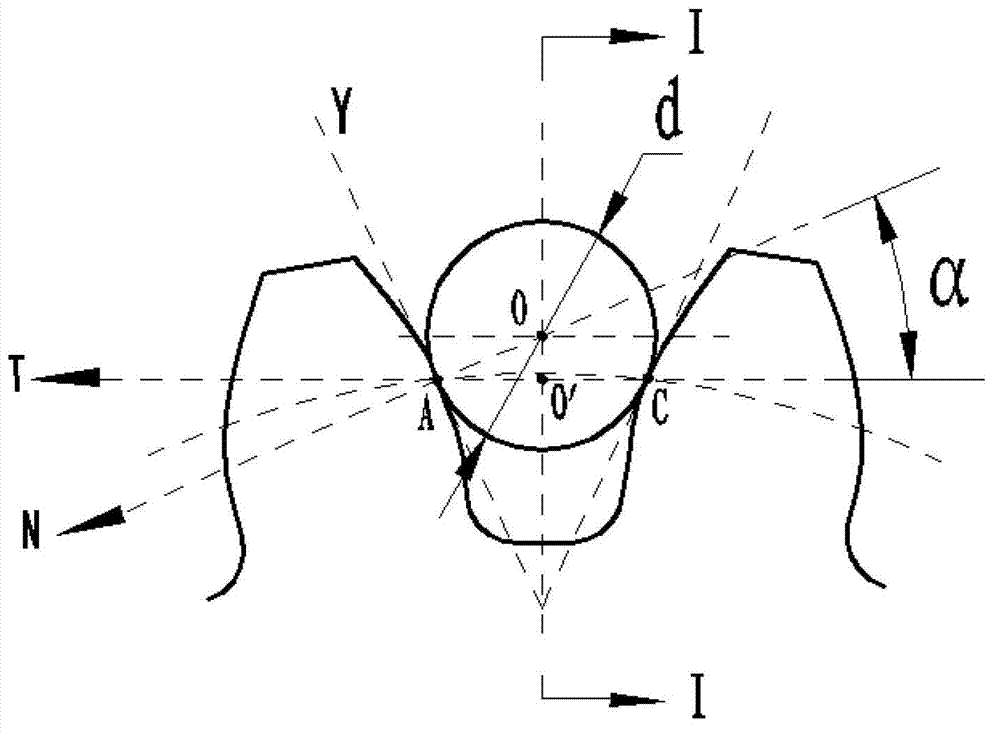

[0027] refer to figure 1 and combine Figure 5 , to illustrate the specific structure of the measuring device of the spur bevel gear of the present invention. The device for measuring the pitch cone angle of the spur bevel gear of this embodiment mainly includes a test rod 3 paired with the standard tooth groove of the spur bevel gear to be tested, a measuring platform 9, and a lever dial gauge 2 placed on the measuring platform 9 , the sine gauge 5 and the adjustable contour block 6 that cooperates with the sine gauge 5 to measure the angle, the upper plane of the sine gauge 5 is provided with the top frame 1 for clamping the straight bevel gear to be tested, and the left and right tops of the top frame are required The connecting line is parallel to the upper plane of the sine gauge.

[0028] Set the top frame 1 on the sine gauge 5, fix the straight bevel gear 4 to be tested on the top frame 1 with the left and right tops 7, the left top here is set as a half top, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com