Resin filling type ion chromatography electrolysis self-regeneration suppressor

An ion chromatography and filling technology, which is applied in the field of resin-filled ion chromatography electrolysis self-regenerating suppressor, can solve the problems affecting the baseline and peak shape, interlayer liquid leakage, filling material extrusion, etc., to reduce deformation and pipeline interface Less, controlled deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

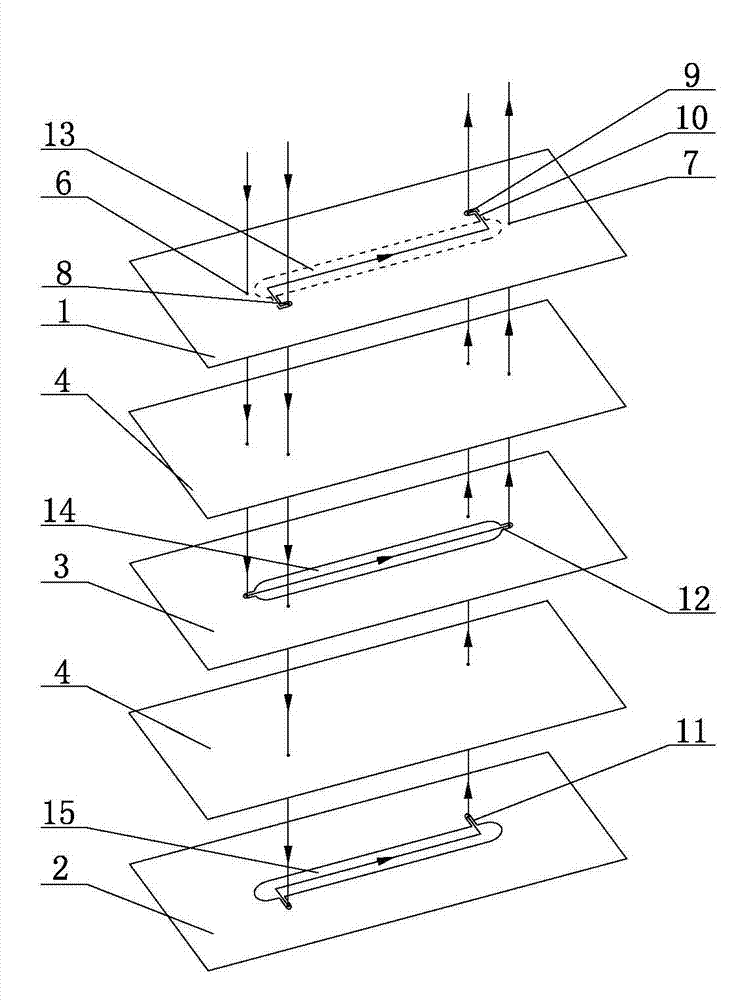

[0019] Description with reference to the accompanying drawings.

[0020]From top to bottom in the drawings are splint I1, ion exchange membrane 4, middle layer 3, ion exchange membrane 4 and splint II2, which are fixed together by fastening screws whose surface is coated with insulating material. In order to clearly illustrate the structure of the embodiment, the drawings of this embodiment show the splint I1, the ion exchange membrane 4, the intermediate layer 3, the ion exchange membrane 4 and the splint II2 separately, without drawing the fastening screws. The ion exchange membranes 4 between the splint I1 and the middle layer 3 and between the middle layer 3 and the splint II2 are both anion exchange membranes or cation exchange membranes, and in this embodiment are cation exchange membranes. Plywood I1 and Plywood II2 are made of reinforced nylon material with good resistance to organic solvents. There is a splint I electrolysis chamber 13 on the splint I1, and a splint ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com