Ultra-hysteresis dipole transverse wave source

A technology of dipole shear wave and hysteresis, which is applied in the field of hyperhysteresis dipole shear wave source, can solve the problems of waste of manpower and material resources, influence of propagation depth, and lower signal quality, and achieve high transmission power, short aftershocks, and good interference characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

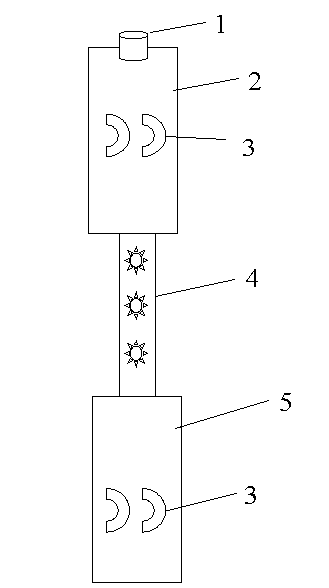

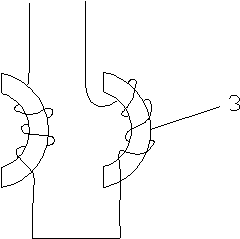

[0010] Such as figure 1 and figure 2 As shown, in the present invention, the super hysteresis sheet 3 of super hysteresis material is adopted, and the tubular super hysteresis material is divided into two identical halves, which are respectively wound in opposite directions on the two halves of the super hysteresis sheet 3 Coils with the same number of turns are pressed and fixed with tie rod nuts, and their two sides are respectively coupled and contacted with the launch plate to form a complete core component of the hyperhysteresis dipole shear wave source; the hysteresis dipole shear wave source includes the above core In addition to the components, it also includes the source signal emitter 5, the vibration signal receiver 2, the sound insulation tube 4 is connected between the emitter 5 and the receiver 2, and the emitter 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com