Pin component for optical fiber adaptor connector

A transfer connector and ferrule technology, which is applied in the field of ferrule components for optical fiber transfer connectors, can solve the problems of increased production cycle, low pass rate, and low production efficiency, and achieve simple manufacturing process, shortened production cycle, and qualified high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

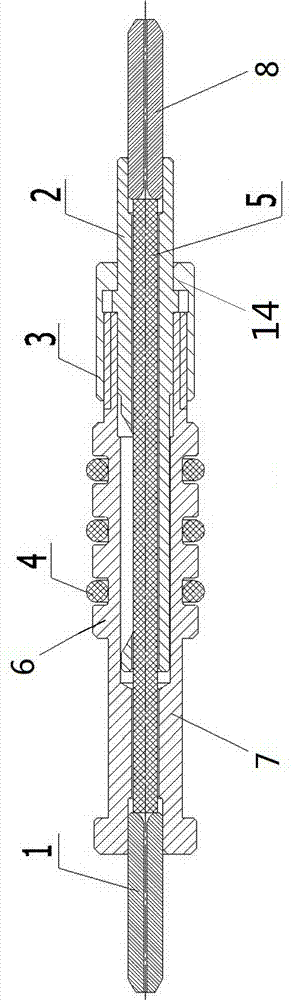

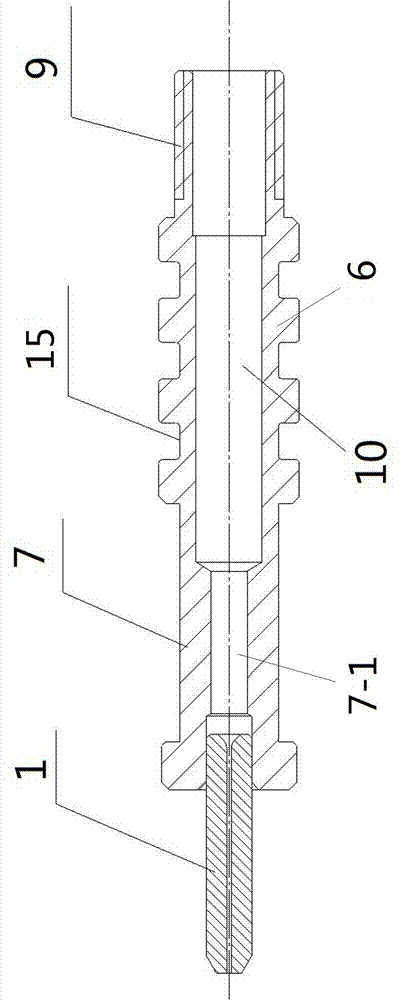

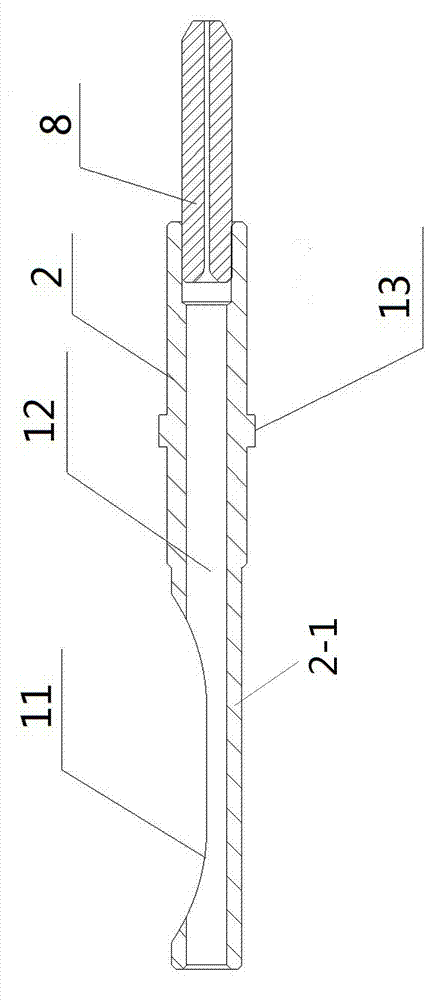

[0018] Examples of ferrule assemblies for fiber optic transition connectors are Figure 1~3 Shown: including the sheath 6 and the front flange 7 and the rear flange 2 respectively assembled at the front and rear ends of the sheath 6, the front flange 7 and the sheath 6 are integrated, the rear flange 2 and the sheath Split settings. The pin assembly also includes a front pin 1 and a rear pin 8 respectively crimped and fixedly connected to the front and rear flanges, and an optical cable 5 connecting the two ceramic pins. The rear flange 2 is provided with an optical cable installation hole 12 connected to the front end of the rear pin 8, the rear end of the optical cable 5 is fixed in the optical cable installation hole 12, and the optical cable 5 is inserted into the sheath 6 after the flange 2 In the hole 10, the pin assembly also includes a fixed connection structure for connecting and fixing the sheath 6 and the rear flange 2 after the optical cable 5 and the flange 2 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com