Working method of permanent magnet coil driving circuit

A technology of coil driving and working method, applied in the direction of electromagnets, electromagnets with armatures, etc., can solve the problems of occupation, multi-port resources, H-bridge burning, etc., and achieve the effect of preventing overload, saving port resources, and avoiding burning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

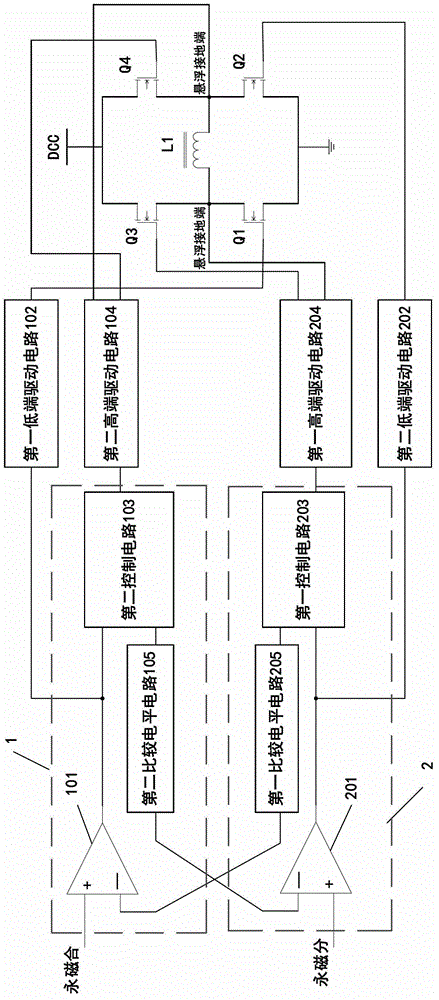

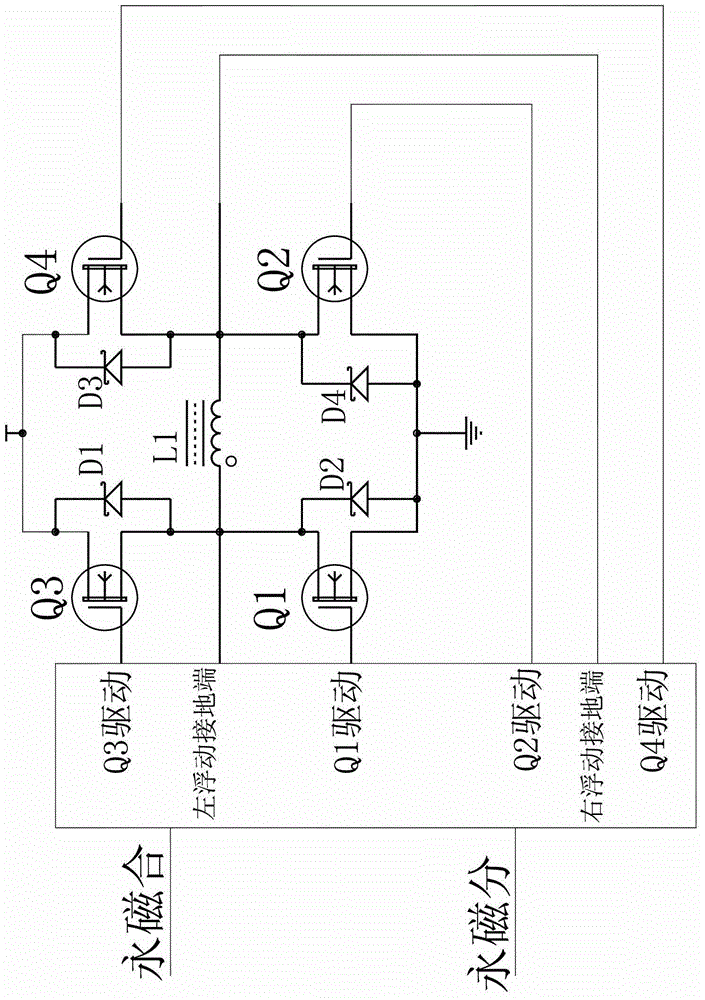

[0045] See figure 1 , 2 , a permanent magnet coil drive circuit, comprising: an H-bridge composed of a first low-end switch tube Q1, a second low-end switch tube Q2, a first high-side switch tube Q3, and a second high-side switch tube Q4, wherein the first A low-side switch tube Q1 and a second high-end switch tube Q4 are paired tubes for the first group of control coils L1 to be energized, and the second low-side switch tube Q2 and the first high-side switch tube Q3 are for the second group to control the coil L1. Electric pair tubes, each high-end switch tube is connected to the corresponding high-end drive circuit, and each low-end switch tube is connected to the corresponding low-end drive circuit;

[0046] It also includes: respectively controlling the first and second groups of tube control circuits with the same structure; the first pair of tube control circuits 1 and the second group of tube control circuits 2 both include : Comparator, control circuit, comparison le...

Embodiment 2

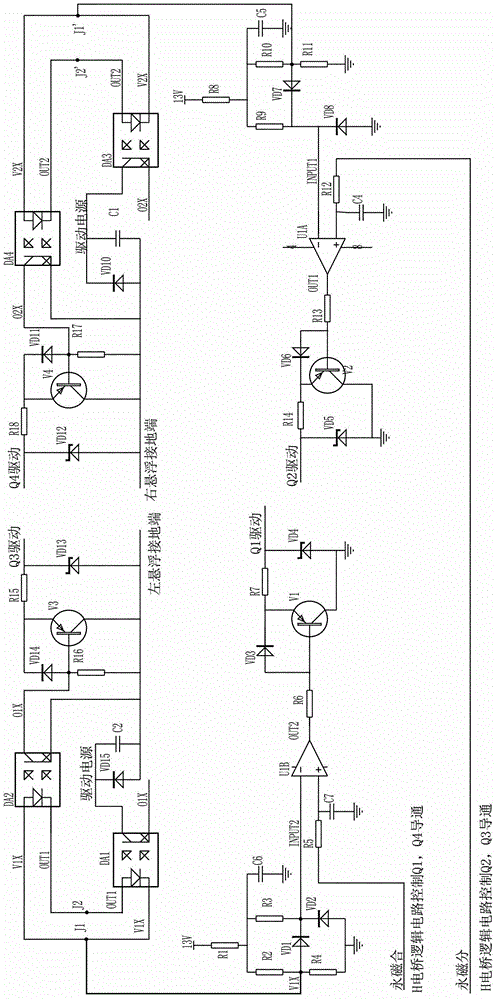

[0070] See image 3 , image 3 The specific circuit implementation and principle of the switch tube drive circuit are shown; for the sake of simplicity, the same or similar components use the same or similar labels; in this implementation, the comparator uses a dual comparator integrated circuit, so the first The label of the first comparator is changed to U1B, and the label of the second comparator is changed to U1A.

[0071] On the basis of Embodiment 1, the switching tube can be replaced by a MOS tube, and the driving principle of the H bridge is as follows:

[0072] This circuit fully considers the driving reliability of the H bridge, and completely avoids the direct connection of the upper and lower bridge arms during the circuit design. The specific truth table is shown in Table 1:

[0073] Table 1 Driving truth table of H bridge

[0074]

[0075] The working principle of the circuit is as follows: the circuit is mainly composed of two comparators, four optocoupler...

Embodiment 3

[0084] See Figure 1-5 , on the basis of embodiment 1, a kind of working method of permanent magnet coil drive circuit, comprises:

[0085] ① The permanent magnet coupling and permanent magnet sub-control signals output by the processor are respectively connected to the non-inverting terminals of the first comparator 101 and the second comparator 201; wherein the high level of the permanent magnet coupling and permanent magnet sub-control signals is 5V, The low level is 0V; the power supply voltage of the first comparator 101 and the second comparator 201 is 5-20V, generally 13V; the power supply of the comparison level circuit is also 13V.

[0086] ② If the permanent magnet coupling control signal is high level, and the permanent magnet sub-control signal is low level, then the voltage at the non-inverting terminal of the first comparator 101 is higher than the voltage at the inverting terminal, and the first comparator 101 outputs a high level to control the first low-side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com