Catalyst for yield increases of BTX (benzene, toluene and xylol) aromatic hydrocarbons and trimethylbenzene through hydrocracking heavy aromatic hydrocarbons

A technology for BTX aromatics and hydrocracking, which is applied in the direction of molecular sieve catalysts, physical/chemical process catalysts, hydrocarbons, etc., and can solve the problems of long trimethylbenzene monomer flow, difficult separation, and insufficient removal capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

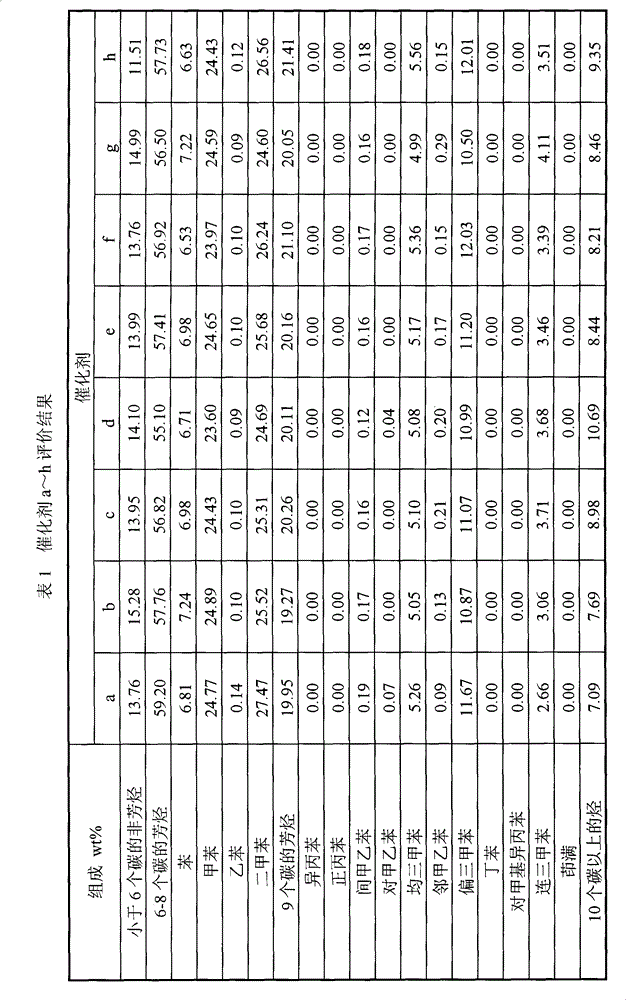

Examples

Embodiment 1~2

[0018] Binder-free ZSM-5 zeolite (SiO 2 / Al 2 o 3 The molar ratio is 60) prepared with reference to Chinese patent CN100384735C, the prepared binderless ZSM-5 zeolite crushing strength is greater than 75N / particle, the weight content of ZSM-5 zeolite is 98.5%, the product is ion-exchanged with ammonium nitrate solution, and after exchange Carry out roasting and transform into hydrogen-type zeolite. On the hydrogen-type binderless ZSM-5 zeolite, impregnate 0.05% Pt and 0.25% Zn by weight, and calcinate at 450°C for 4 hours to obtain catalyst a; on the hydrogen-type binderless ZSM-5 zeolite Catalyst b was obtained by impregnating 0.3% of Pd and 0.05% of Pb in weight ratio, and calcining at 450° C. for 4 hours.

Embodiment 3~5

[0020] Binder-free ZSM-5 zeolite (SiO 2 / Al 2 o 3 The molar ratio is 20) prepared with reference to Chinese patent CN100384735C, the prepared binderless ZSM-5 zeolite has a crushing strength greater than 65N / particle, and the weight content of ZSM-5 zeolite is 99.6%. The product is ion-exchanged with ammonium nitrate solution, and after the exchange Carry out roasting and transform into hydrogen-type zeolite. On the hydrogen-type binderless ZSM-5 zeolite, impregnate 0.005% of Pt and 0.01% of Sn by weight, and calcined at 450°C for 4 hours to obtain catalyst c; on the hydrogen-type binderless ZSM-5 zeolite Impregnate 0.5% of Pd, 0.01% of Zn and 1.0% of La by weight, and calcinate at 450°C for 4 hours to obtain catalyst d; impregnate 0.03% by weight of hydrogen-type binder-free ZSM-5 zeolite Pt, 0.02% Bi and 0.2% Sn were calcined at 450° C. for 4 hours to obtain catalyst e.

Embodiment 6~7

[0022] Binder-free ZSM-11 zeolite (SiO 2 / Al 2 o 3 The molar ratio is 45) prepared with reference to Chinese patent CN101348261A, the prepared binderless ZSM-11 zeolite crushing strength is greater than 80N / particle, the weight content of ZSM-11 zeolite is 97.9%, the product is ion-exchanged with ammonium nitrate solution, after exchange Carry out roasting and transform into hydrogen-type zeolite. On the hydrogen-type binderless ZSM-11 zeolite, impregnate 0.06% of Pt and 0.2% of Zn by weight, and calcinate at 450°C for 4 hours to obtain catalyst f; on the hydrogen-type binderless ZSM-11 zeolite Catalyst g was obtained by impregnating 0.2% Pt and 0.20% Bi by weight and calcining at 450° C. for 4 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com