Strip steel C warping control method

A control method and strip technology, applied in the direction of profile control, etc., can solve the problems of harsh production environment, different warpage, and different operating levels of operators, so as to ensure the quality of strip steel and improve the yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

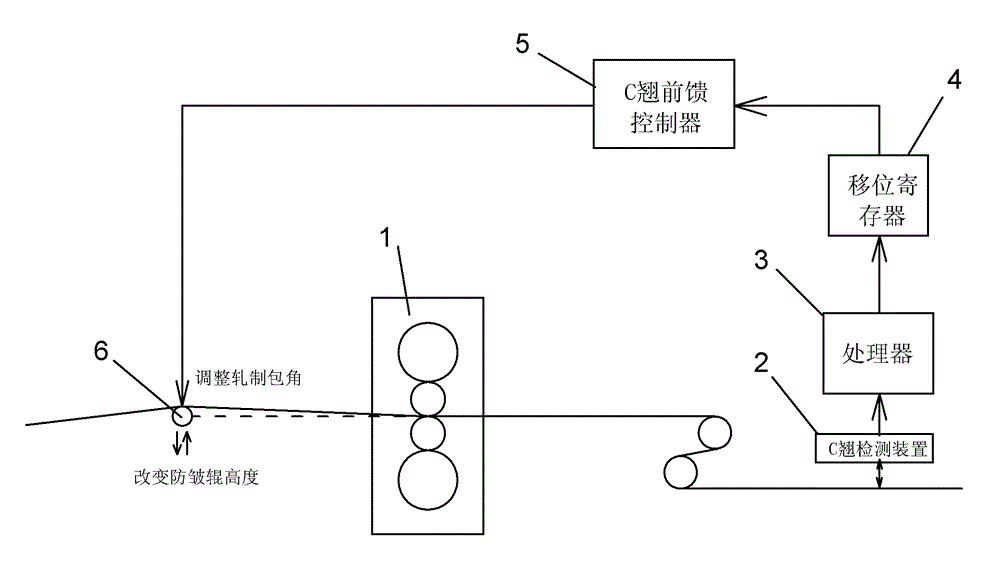

[0037] The principle block diagram of the strip steel C warping control method of the present invention is as figure 1 As shown, the method mainly includes the following four steps:

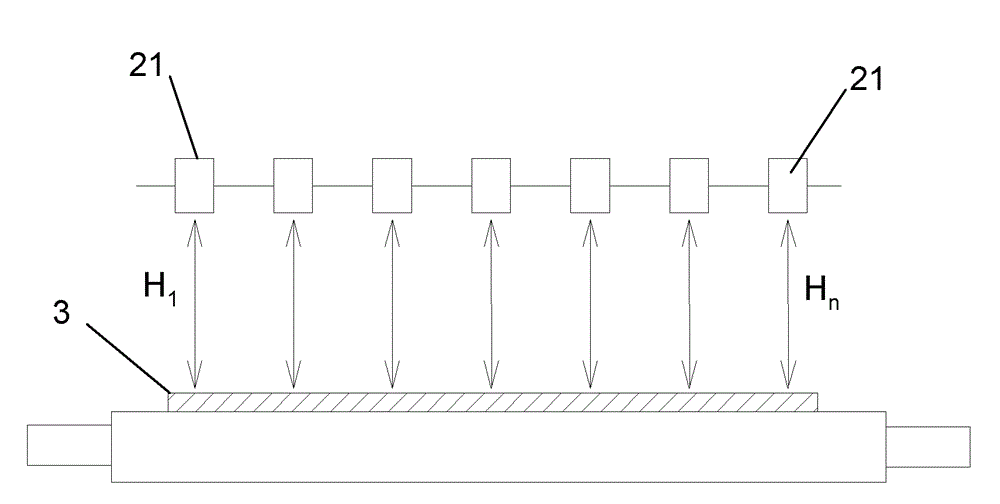

[0038] A. Install a strip steel C warpage detection device 2 at the entrance of the rolling mill 1 or the skin pass mill to detect the incoming strip steel 7 in real time and obtain the warpage amount of the strip steel 7;

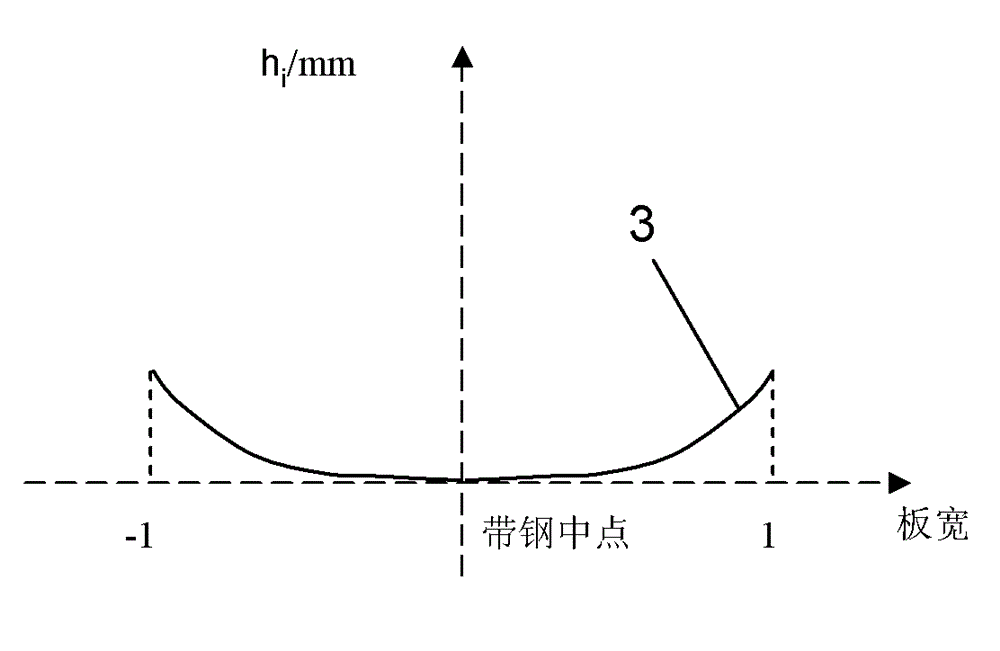

[0039] B. Perform fitting processing on the warpage amount by processor 3 to obtain a warpage height value representing the degree of C-warping of the strip;

[0040] C. Perform displacement processing on the warpage height value through the shift register 4 and delay the output to obtain the warpage height value currently entering the rolling mill 1 or skin pass mill for feed-forward control;

[0041] D. Calculate and cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com