Numerical control processing machine tool and processing method special for double-power unit propeller

A CNC machining machine tool and dual power head technology, which is applied to metal processing machinery parts, metal processing equipment, milling machine equipment, etc., can solve the problems of adverse effects on propeller machining accuracy, propeller turning, difficulty in clamping, and influence of propeller machining accuracy, etc. Achieve the effects of shortening the production cycle, reducing labor intensity and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

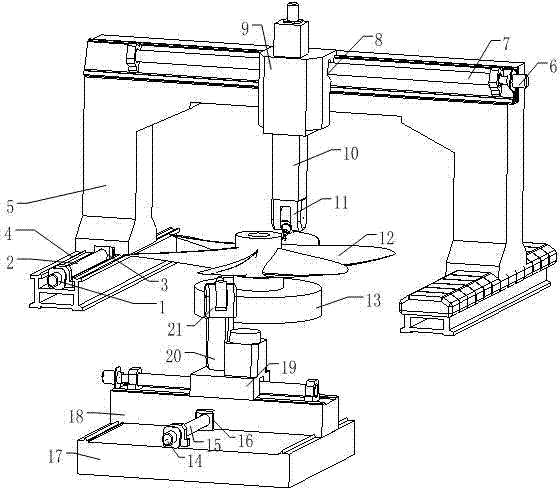

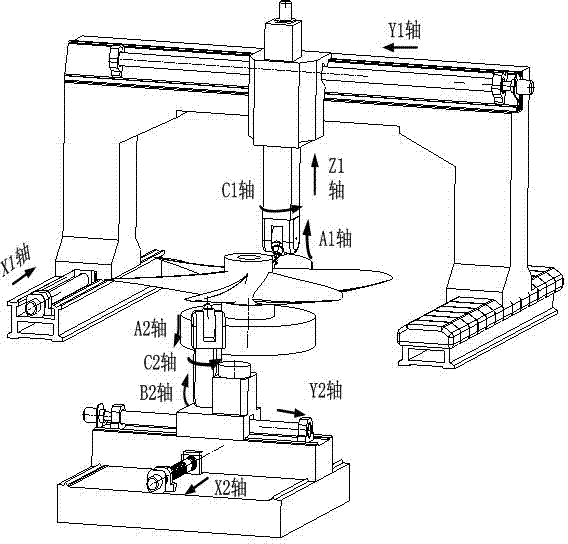

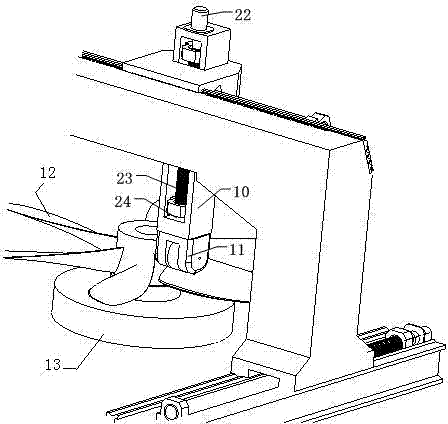

[0017] like figure 1 As shown, the special CNC machining machine tool with dual power heads propellers of the present invention includes two sets of power head systems and a rotary table 13, the rotary table 13 is used to place the workpiece propeller 12 to be processed, and the two sets of power head systems are respectively used to process the propeller 12 The upper and lower surfaces of the blades are used to process the pressure surface of the blade and the suction surface of the blade, and are also used to process the guide edge, hub and blade root of the propeller 12.

[0018] The upper power head system for processing the upper surface of the propeller includes an upper base 4, a moving column 5, a first lead screw and nut mechanism, a motor, guide rails and an A / C direct-drive double swing power head 11. The moving column 5 is an inverted U-shaped structure, the X1 axial guide rail is arranged on the upper surface of the upper base 4, and the first screw nut mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com