Automatic cutting equipment for blocking and processing stone floor

A technology for cutting equipment and floors, which is applied in stone processing equipment, work accessories, manufacturing tools, etc., can solve the problems that affect the popularization of production and use of stone floors, the inability to process the assembly structure of stone floors, and the inability to cut and process equipment to achieve hardness. Fit, reduced positioning, easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention can have various changes in different embodiments, which do not depart from the scope of the present invention, and the descriptions and drawings therein are essentially for illustrative purposes, rather than limiting this invention.

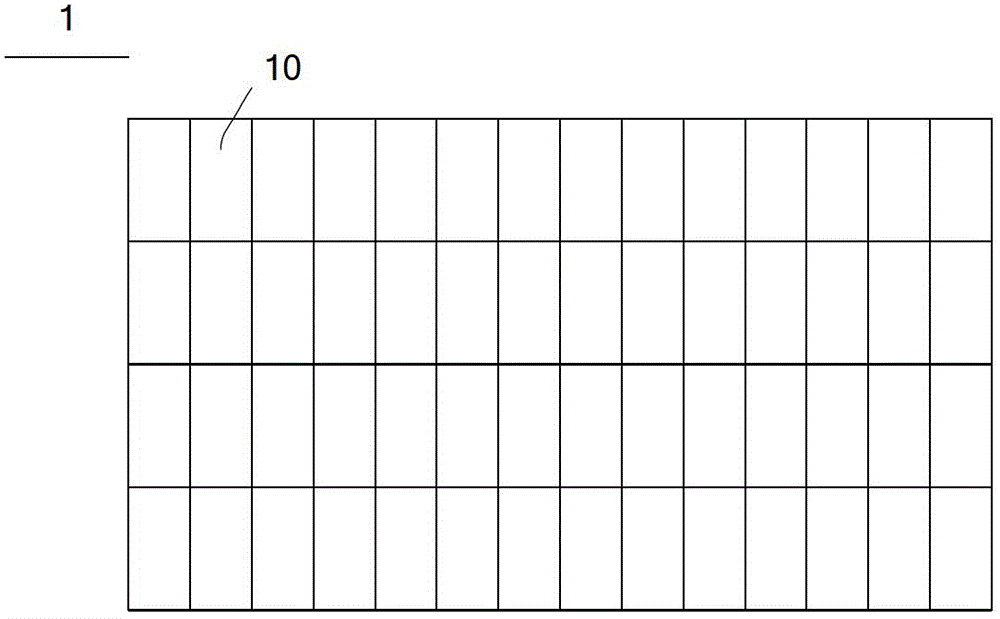

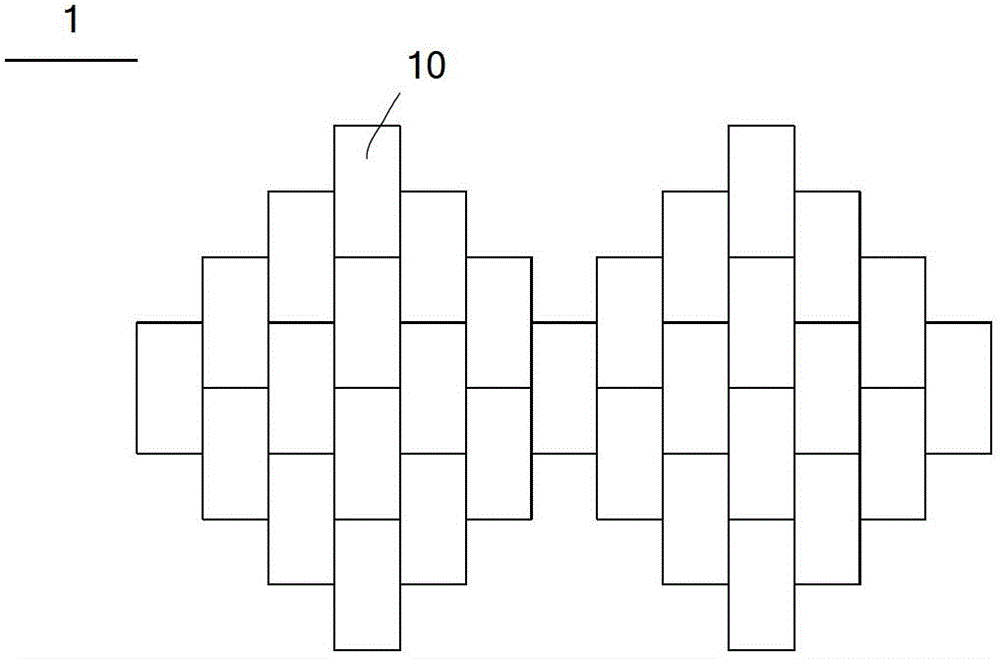

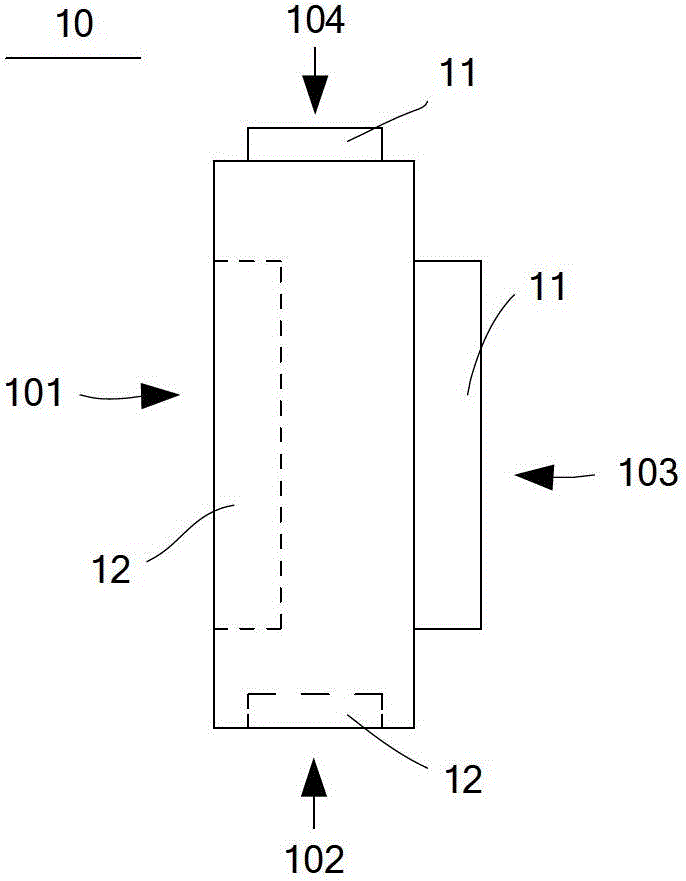

[0033] Such as figure 1 versus figure 2 As shown, the present invention provides a hard floor 1, which is different from traditional wooden floors and the like, and has a relatively high hardness, which can reach Mohs hardness above 7.0. The hard floor 1 is different from traditional wooden floors. Compared with other materials, it has the advantages of high hardness, not easy to deform, long service life and unique visual effect, so it has broad development prospects.

[0034] The materials selected for the hard floor 1 mainly include stone, ceramics a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com