Block rubber breaking machine

A block breaking machine and rubber technology, which is applied in the direction of mechanical material recycling, recycling technology, plastic recycling, etc., can solve the problems of large tool loss, large floor space, high energy consumption, etc., and achieve high production efficiency, labor saving, and high efficiency. significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

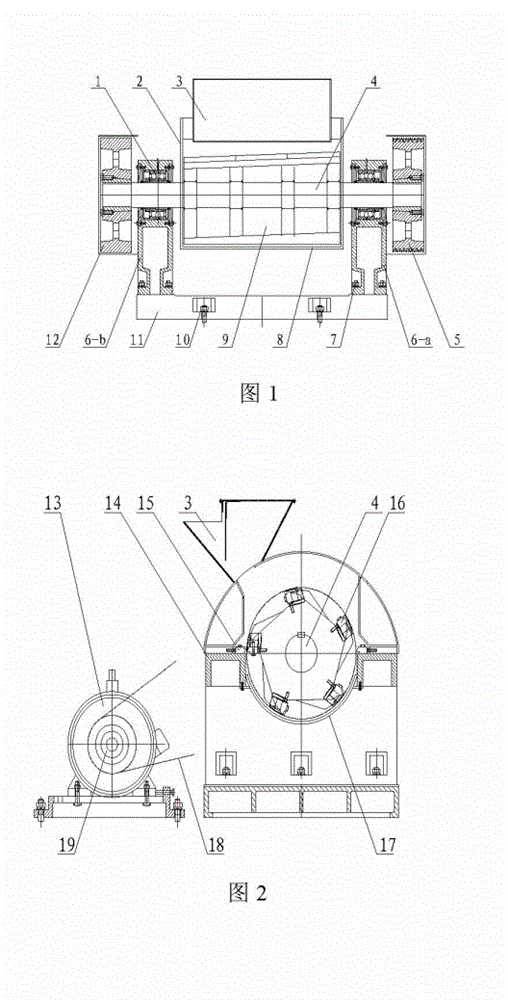

[0021] Taking the example of crushing the sidewall of a tire whose outer diameter is not greater than Φ1200mm from which the bead rim has been removed, the structure and function of the rubber breaker will be described in detail.

[0022] Figure 1 and figure 2 As shown, the structure of the rubber breaker is mainly composed of a base 11, a support 6, a cutter device 9, a crushing chamber 8, a hopper 3 and a transmission system; the base 11 is fixed on the ground by eight anchor bolts 10, and the support 6 It is divided into two parts, the right support 6-a and the left support 6-b, which are respectively fixed on the base 11 by six studs 7; the support 6 is equipped with a spherical roller bearing 1 and a knife seat 14, and the The cutter device 9 is installed on the 14; the motor 13 of the transmission system transmits power through the small pulley 19, the large pulley 5 and the belt 18, and drives the cutter device 9 to rotate; 2. The fully enclosed cutter device 9, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com