Suspending swing arm assembly

A suspension pendulum, assembly technology, applied to the cantilever mounted on the pivot, suspension, transportation and packaging, etc., can solve the problems of shaking or difficulty in returning, bad steering wheel, direction failure, etc., and achieve increased wear resistance. , good safety, good ride comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

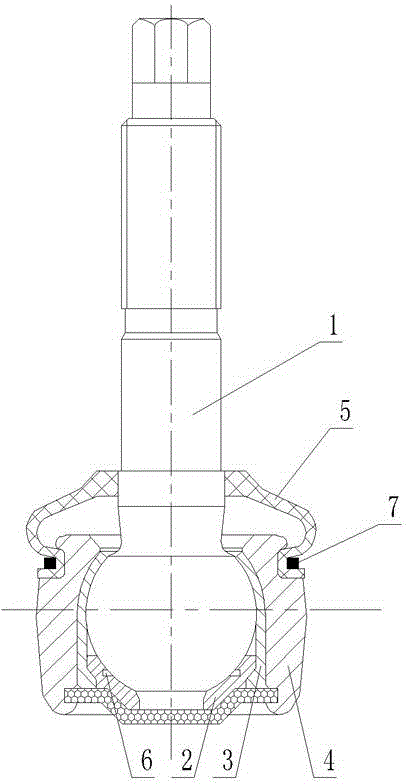

[0012] Such as figure 1 As shown, the suspension swing arm assembly of the present invention includes a ball pin 1, an inner ball seat 2, an outer ball seat 3, and a housing 4 that are installed sequentially from the inside to the outside. The ball pin 1 extends outside the outer wall of the housing 4 and A dust cover 5 is installed between the shells 4, wherein the inner ball seat 2 is made of resin, the ball pin 1, the outer ball seat 3, and the shell 4 are all forged from aluminum-silicon-magnesium alloy; at the same time, the inner ball seat A groove 6 is opened on the inner wall of the inner ball seat 2, and the groove 6 surrounds the inner wall of the inner ball seat 2 in a horizontal circumferential direction. A clip 7 is arranged on the outer wall of the dustproof cover 5 .

[0013] The above-mentioned embodiments are only used to explain the inventive concept of the present invention, but not to limit the protection of the rights of the present invention. Any ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com