Sack packer for automatically collecting grain

An automatic collection and bagging machine technology, applied in the field of agricultural machinery, can solve the problems of low picking work efficiency, manual bag sealing, poor grain collection effect, etc., to achieve the effect of improving collection efficiency and increasing adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

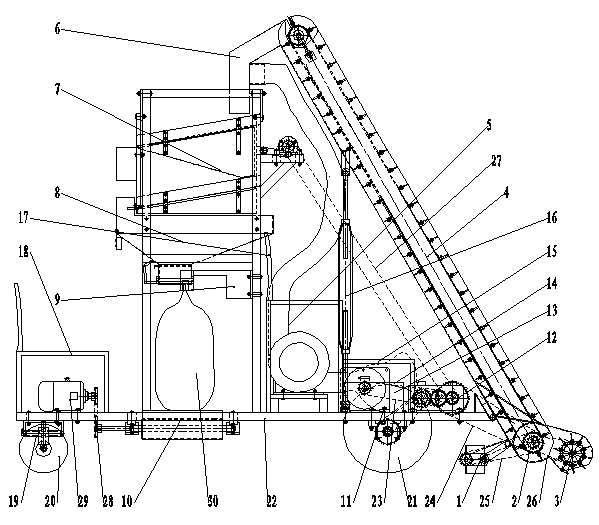

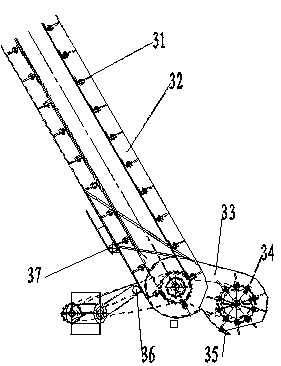

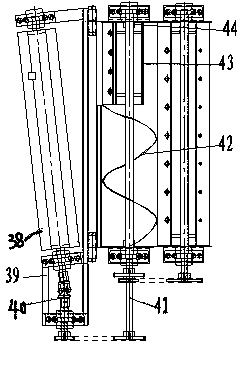

[0024] This embodiment is used to illustrate the present invention, but not to limit the present invention. Such as Figure 1-7 In the shown embodiment: all devices are fixed on the frame (22), and work together under the action of the control system to complete the functions of automatic grain collection, automatic cleaning, quantitative bagging, and automatic bag sealing. When working, the grain diverting device (3) (when the site is uneven, start the leaking grain cleaning device (1)) collects the grain spread on the drying field into the auger (2), and the auger (2) transports the grain to The elevator (4), the elevator (4) lifts the grain to the grain feeding mechanism (6), and during the falling process of the grain, the wind-powered impurity removal device (5) sucks away the light impurities mixed in it, and at the same time After a certain air-drying effect, the vibrating screen and magnetic impurity removal device (7) remove and collect impurities of different sizes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com