Magnetic plate liquid purifying device

A liquid purification, magnetic plate technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. , fixed on the surface of the disk, etc., to achieve the effect of not being limited by the water quality, good solid-liquid separation effect, and easy to ensure manufacturing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

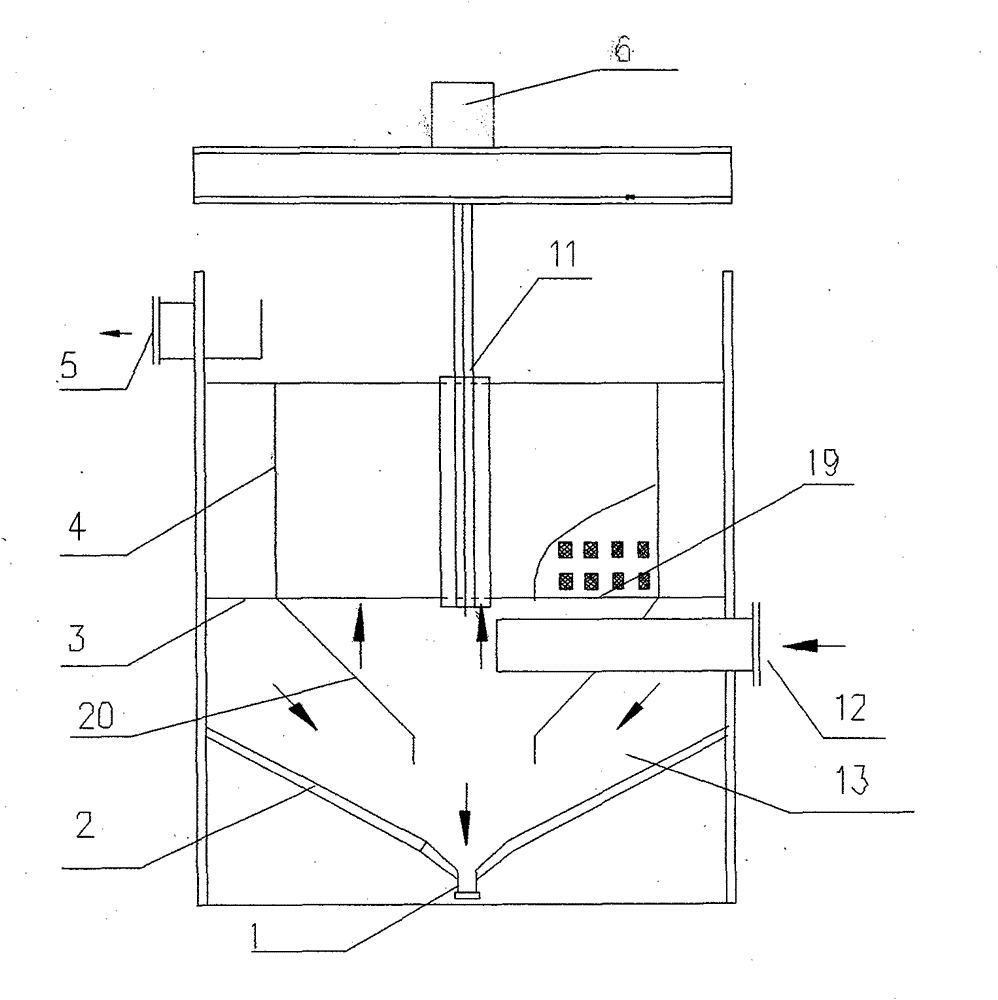

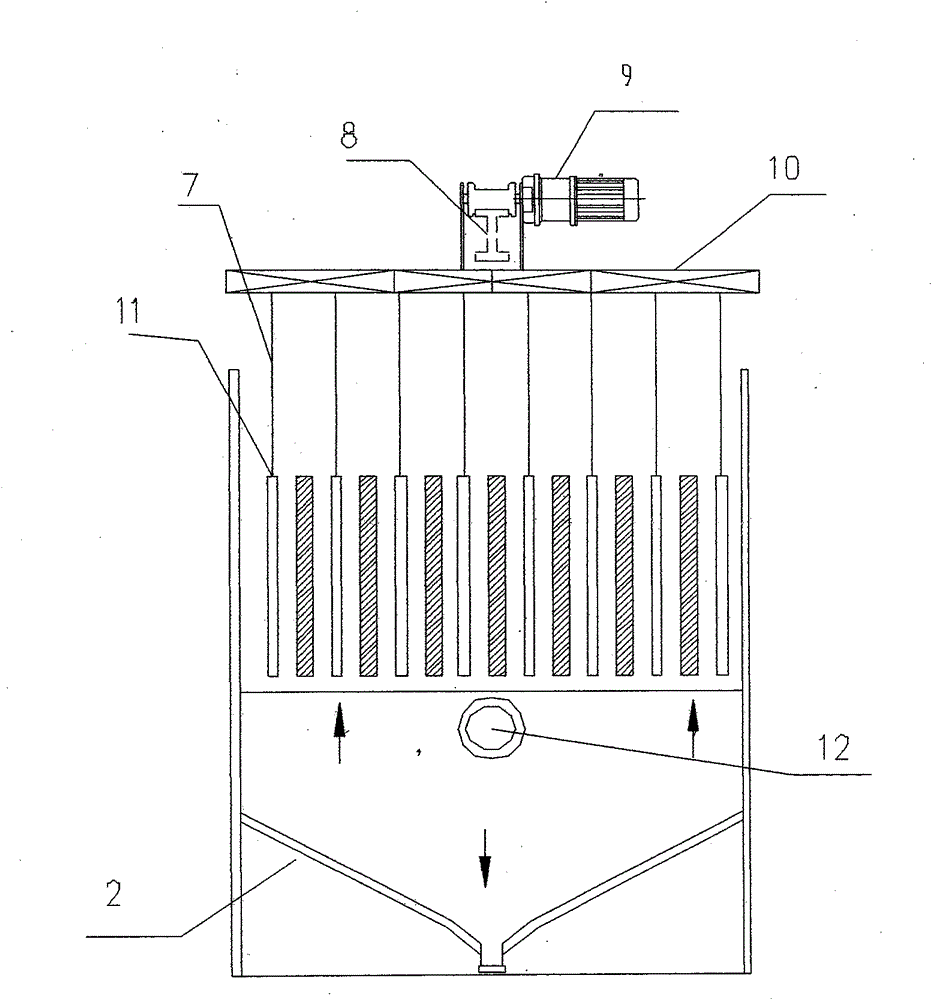

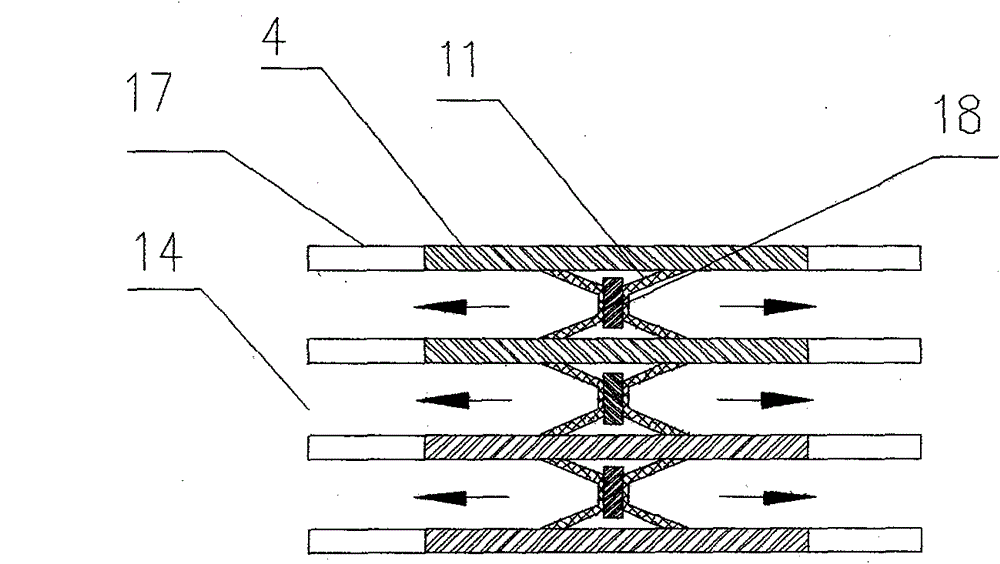

[0019] Such as figure 1 , figure 2 As shown, the magnetic plate liquid purification equipment of the present invention includes a separator, a slag scraping mechanism, and a slag discharge mechanism. The separator 4 is arranged in parallel by two or more magnetic plates, and is vertically fixed on the separator support of the inner wall of the tank body 2. On the frame 19, wherein each magnetic plate is made up of a magnetic adsorption area 16 and a non-magnetic slag discharge area 17, the non-magnetic slag discharge area 17 of all magnetic plates is arranged in a straight line along the radial direction of the magnetic plate, between the magnetic plate and the magnetic plate The waste water channel 14 is formed between them; the slag scraping mechanism includes a reciprocating mechanism 6 and a slag scraping bar 11, and the reciprocating mechanism 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com