Method for preparing functionalized graphene oxide

A graphene and functionalization technology, applied in organic chemistry, etc., can solve the problem of graphene oxide dispersion not being well resolved, limited application, etc., and achieve low pollution, high utilization rate and simple operation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

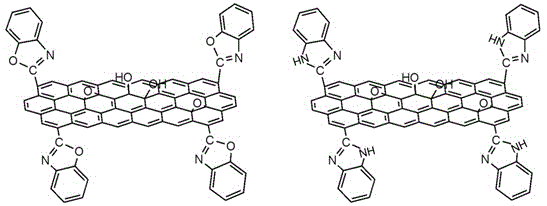

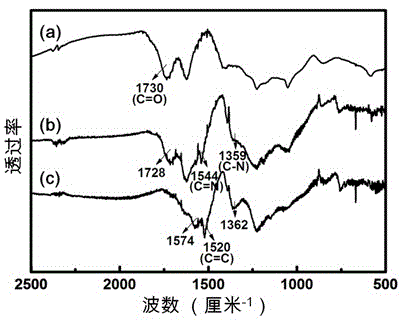

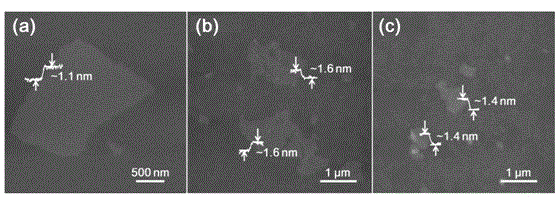

[0023] The present invention proposes a novel method for preparing functionalized graphene oxide, which is a graphene oxide functionalization process catalyzed by polyphosphoric acid at room temperature; specifically includes: dispersing graphite oxide into water or an organic solvent, and ultrasonicating for 30-60 minutes , add o-hydroxyaniline or o-phenylenediamine and stir evenly, then add polyphosphoric acid to catalyze, stir at room temperature for 5-7 days, filter with suction, wash the filter cake with dilute hydrochloric acid and water successively, and dry in vacuum to obtain functionalized graphene oxide material. The material can be dissolved in commonly used organic solvents, such as o-hydroxyaniline functionalized graphene oxide can be dissolved in acetonitrile, acetone, N-methylpyrrolidone and N,N-dimethylformamide, o-phenylenediamine functionalized The graphene oxide can be dissolved in tetrahydrofuran, N-methylpyrrolidone and N,N-dimethylformamide.

[0024] Th...

Embodiment

[0029] Embodiment: the preparation method of functionalized graphene oxide.

[0030] Disperse graphite oxide powder (160 mg) into organic solvents such as water or tetrahydrofuran (80 ml), and undergo ultrasonic treatment for 30-60 minutes to obtain a dispersed solution of graphene oxide; then add 700 mg of o-hydroxyaniline or o-phenylenediamine Add to the above solution, stir and sonicate for 5-10 minutes, add 1 ml of polyphosphoric acid under vigorous stirring; stir at room temperature for 5-7 days, filter to remove the filtrate, redisperse the filter cake into dilute hydrochloric acid solution and wash for 3-6 times, the solid was washed with deionized water, and finally vacuum-dried for 1-2 days to obtain functionalized graphene oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com