Cleaning agent for removing stains on surface of silicon slice

A silicon chip surface and cleaning agent technology, applied in the field of cleaning agent, achieves good effect, convenient operation and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

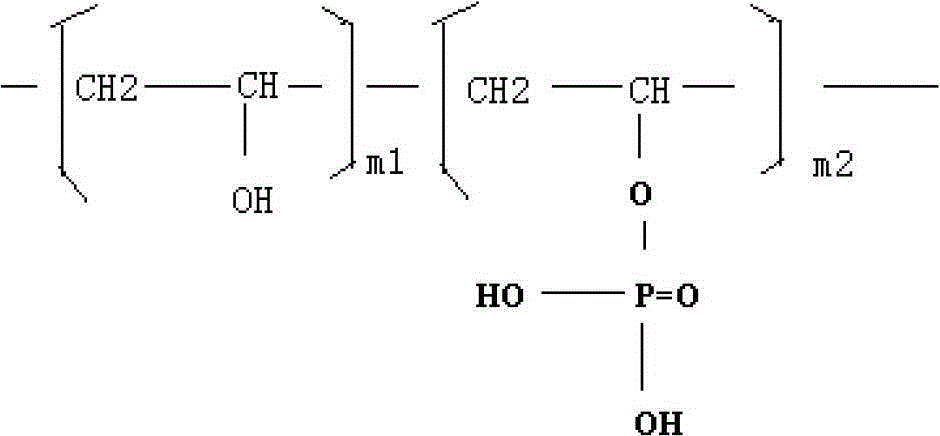

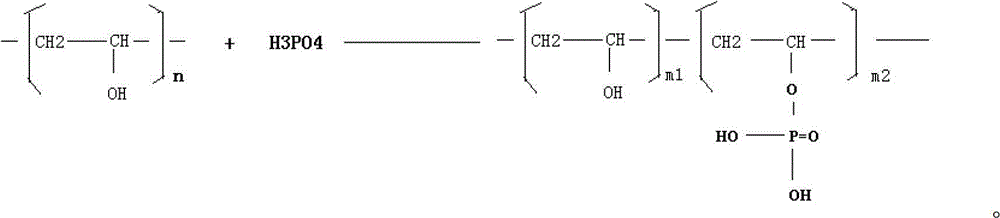

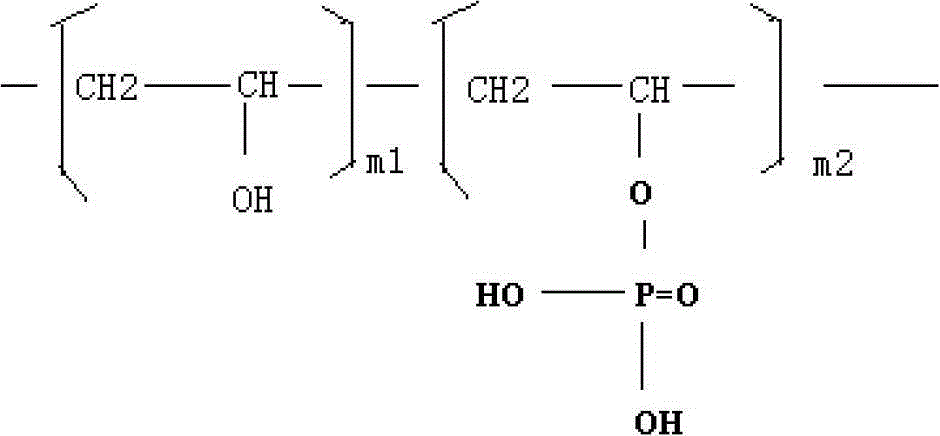

Image

Examples

Embodiment 1

[0021] Polyvinyl alcohol derivative 40%,

[0022] Octylphenylpolyoxyethylene Phosphate 30%,

[0023] OP 1%,

[0024] Sodium Lauryl Thioacetate 20%,

[0025] Water 9%.

[0026] The above-mentioned proportioning components are placed in a stirrer and stirred evenly, and then filled and packaged.

Embodiment 2

[0028] Polyvinyl alcohol derivative 20%,

[0029] Octylphenylpolyoxyethylene Phosphate 50%,

[0030] OP 3%,

[0031] Sodium Lauryl Thioacetate 20%,

[0032] Water 7%.

[0033] The above-mentioned proportioning components are placed in a stirrer and stirred evenly, and then filled and packaged.

Embodiment 3

[0035] Polyvinyl alcohol derivative 30%,

[0036] Octylphenylpolyoxyethylene Phosphate 45%,

[0037] OP 3%,

[0038] Sodium Lauryl Thioacetate 17%,

[0039] Water 5%.

[0040] The above-mentioned proportioning components are placed in a stirrer and stirred evenly, and then filled and packaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com