Prestressed centrifugal square pile

A technology of prestressed and square piles, which is applied in sheet pile walls, buildings, and foundation structure engineering, can solve the problems of reduced bending resistance and poor safety, and achieves the advantages of improved shear resistance, convenient stacking, and high guarantee rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The prestressed centrifugal square pile structure of the present invention will be described in conjunction with the accompanying drawings and embodiments.

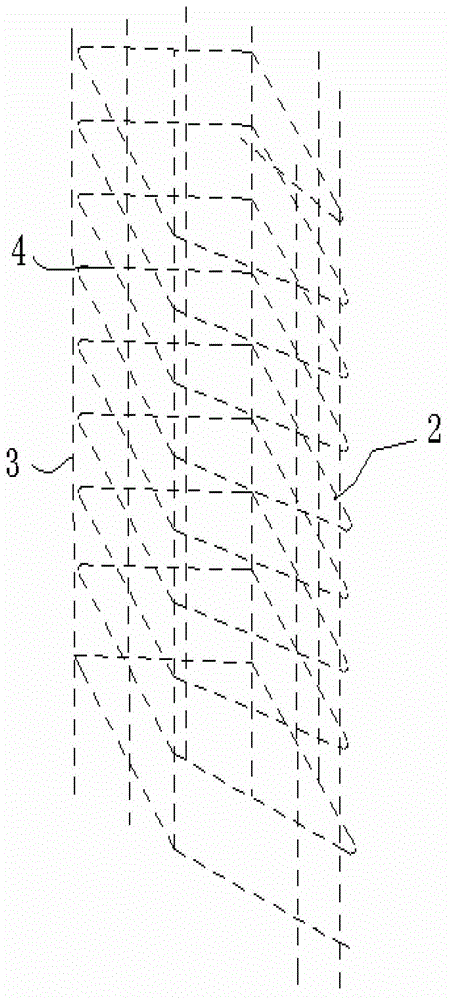

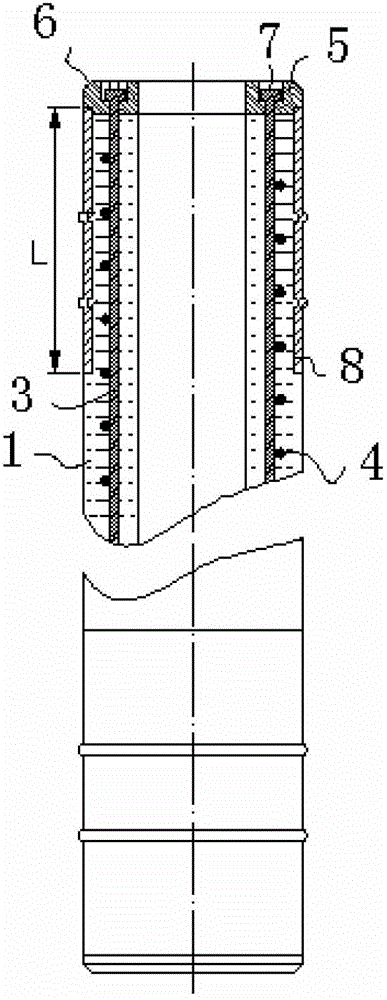

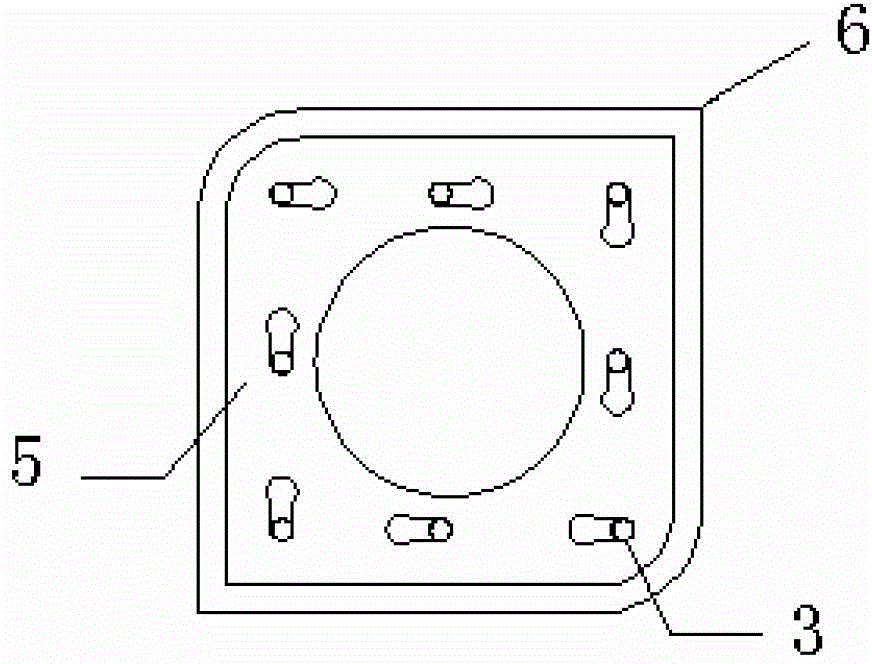

[0021] Such as figure 1 , 2 , 4, the prestressed centrifugal square pile includes concrete 1, reinforcement cage 2, and the reinforcement cage 2 includes the main reinforcement 3 and the stirrup 4, and the stirrup 4 of the reinforcement cage is continuously welded on the main reinforcement 3 in a spiral shape Above; the shape of the prestressed centrifugal square pile is square, the pile core is a cylindrical middle hole, and a pair of arc corners at the corners of the four sides of the pile body are arc-shaped for stress relief, and the radius R of the arc is 5-9mm, and the other The pair is at right angles, so that the pile material is not easily damaged when hammered during construction. Both ends of the pile body 1 are provided with end plates 5 connected with the reinforcement cage 2, which further enhances ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com