Shale gas production increasing method and shale gas production increasing equipment

A technology for shale gas and shale gas wells, which is applied in the direction of earthwork drilling, isolation devices, and production fluids, etc., and can solve the problems of lack of economical and reasonable shale gas stimulation equipment, shortening the effective time of shale gas production, and high preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

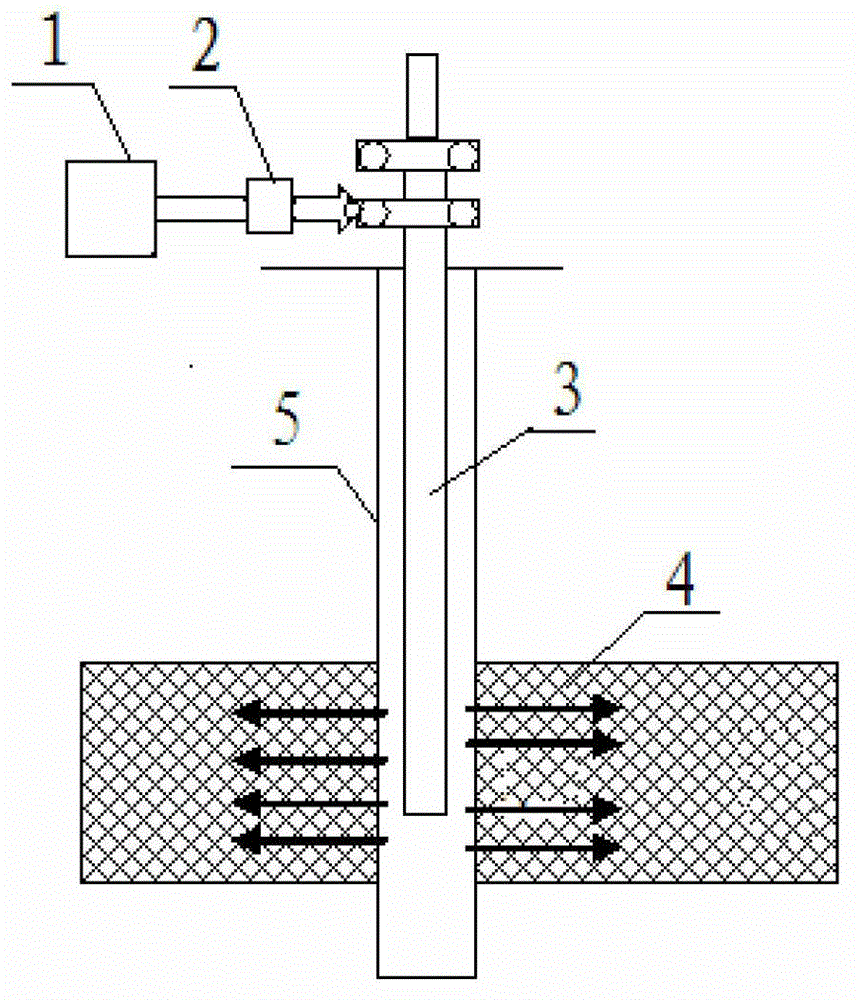

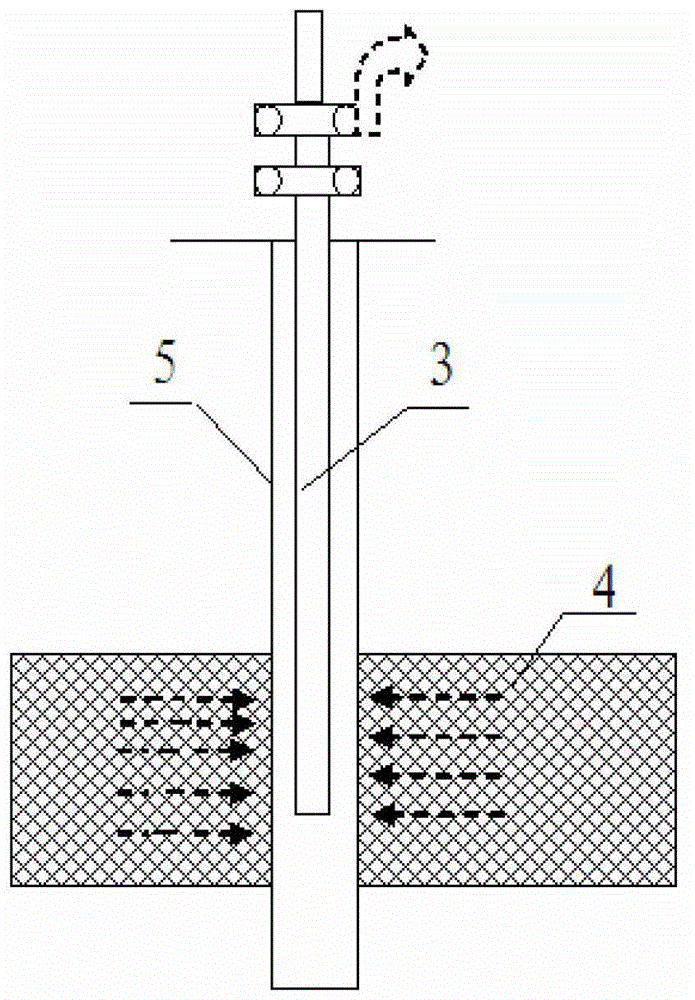

[0037] figure 1 It is a schematic diagram of superheated steam heating in the present invention; figure 2 It is a schematic diagram of superheated steam heating exploitation in the present invention.

[0038]In this embodiment, the shale gas to be exploited is located at a burial depth of about 1000 meters, and the original temperature of the shale layer where the shale gas is located is about 50°C. After a period of normal gas production of shale gas wells, when the daily output of a single well is lower than the industrial development standard (1000 m 3 / day), using the shale gas stimulation method to continue to exploit shale gas, specifically the superheated steam method (also known as superheated steam huff and puff) to exploit shale gas, including the following steps:

[0039] (1) Transport heat energy to the shale layer 4 of the shale gas well, and increase the temperature of the shale layer by driving the transported heat energy to realize heat transfer in the shale...

Embodiment 2

[0044] The difference from Example 1 is that in this example, the superheated steam temperature is 250°C, the steam injection pressure of a single well is 1MPa higher than the shale pore pressure, and the steam injection speed is 10m 3 / h water equivalent superheated steam, so that the dryness of the superheated steam entering the shale layer where the shale gas is located is greater than 60%. The total amount of superheated steam injected is 15 tons of water equivalent steam per meter of shale layer, so that the average temperature of the shale layer within a radius of 50 meters from the shale gas well will increase by 30°C.

[0045] In this example, the temperature of the original formation is about 50°C. After heating, the average temperature of the shale layer within a radius of 50 meters from the bottom of the shale gas well can reach 80°C. At this time, the adsorption capacity of the shale layer is reduced to about 1 / 10 of the original, and the desorption rate is about 1 / ...

Embodiment 3

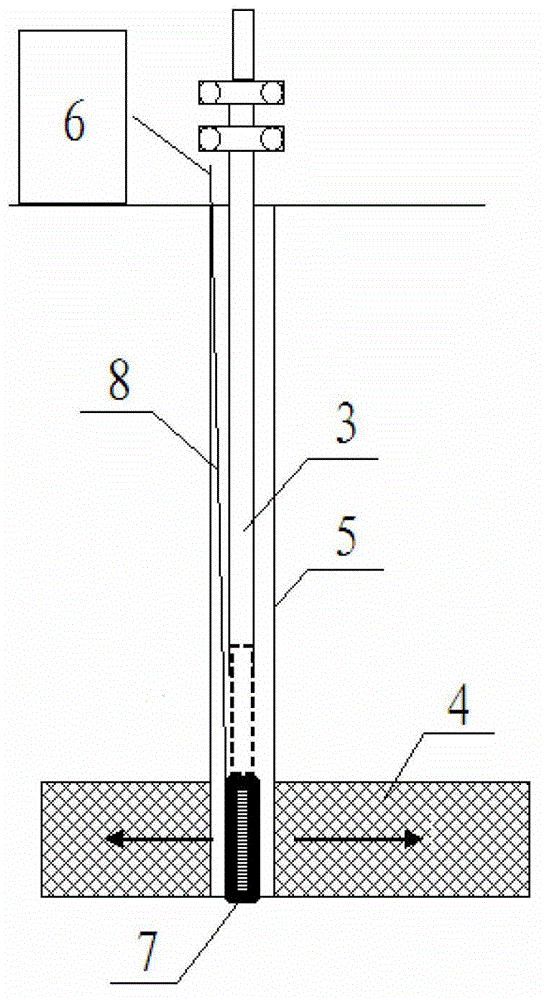

[0047] image 3 It is a schematic diagram of microwave heating of the present invention; Figure 4 It is a schematic diagram of microwave heating mining in the present invention.

[0048] In this embodiment, the shale gas to be exploited is located at a burial depth of about 800 meters in the shale layer, and the original temperature of the shale layer is about 40°C. After a period of normal gas production of shale gas wells, when the daily output of a single well is lower than the industrial development standard (1000 m 3 / day). Using the shale gas stimulation method to continue to exploit shale gas, specifically to exploit shale gas by microwave heating, includes the following steps:

[0049] (1) Transport heat energy to the shale layer 4 of the shale gas well, and increase the temperature of the shale layer by driving the transported heat energy to realize heat transfer in the shale layer 4; specifically, place the microwave generator 7 in the shale layer The shale laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com