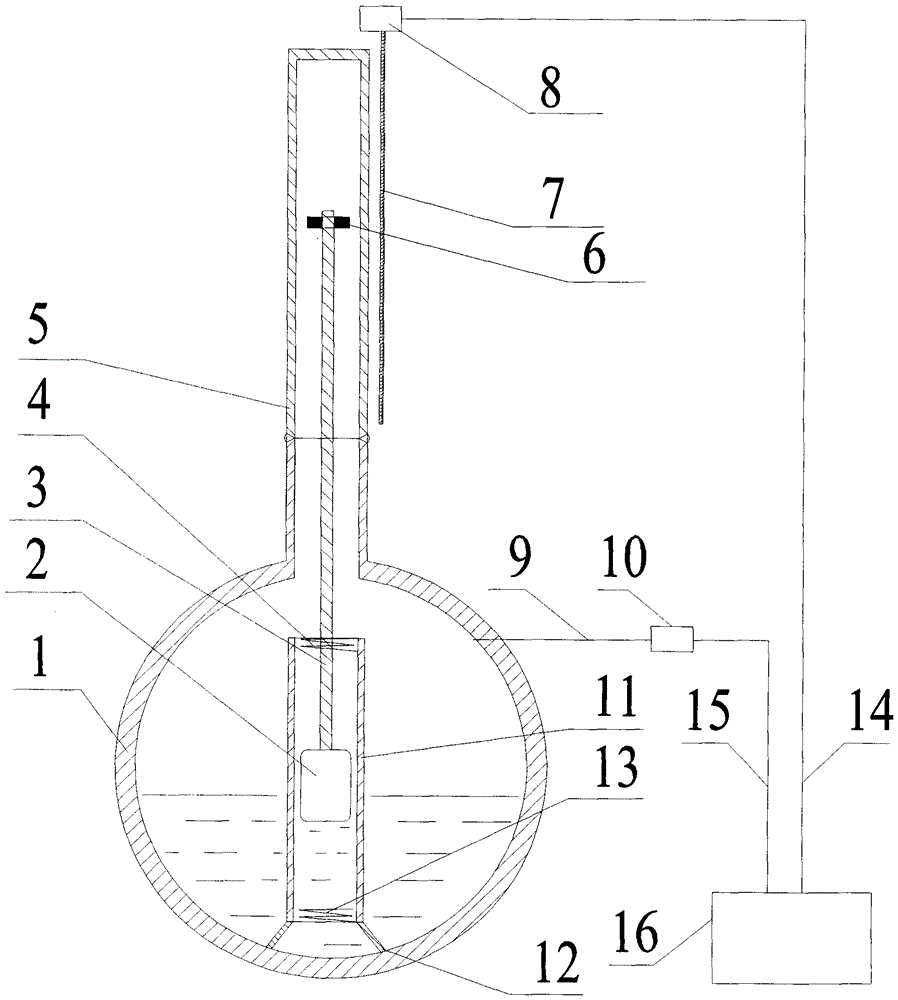

Built-in magnetic liquid level gauge

A liquid level gauge and magnetic induction technology, applied in the field of industrial measurement, can solve the problems of high temperature resistance loss of magnetic field strength, influence of waveguide measurement accuracy, unsatisfactory shape design, etc., to achieve timely and reliable measurement, ensure service life, and prevent jamming astringent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

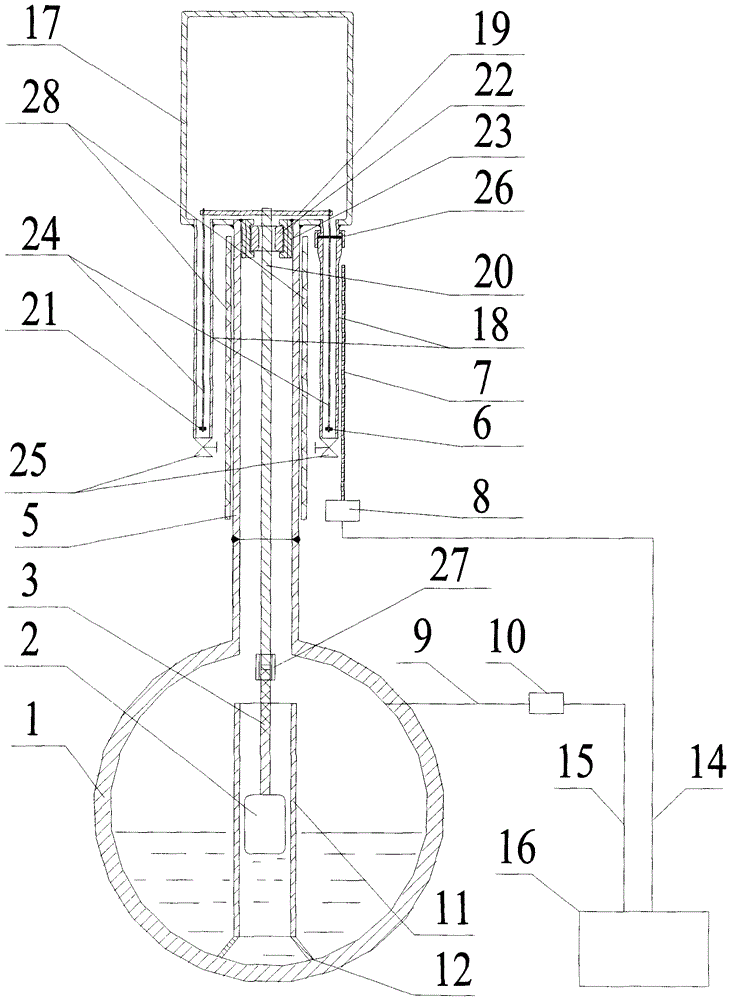

[0009] Such as figure 2 As shown, the protective sleeve (11) is fixedly installed in the container (1) through the mounting bracket (12); the float (2) is placed in the protective sleeve (11); the float (2) is welded with a connecting rod (3) The connecting rod (3) is connected with the upper connecting rod (20) through the sleeve (27); there are three holes at the bottom of the upper cylinder (17), and the holes on both sides are connected with one left and one right cryogenic pipes (18), in the middle The hole is connected to the container (1) by welding or flange connection to the cylinder (5). There are two connection methods. One is to connect according to the welding method of the cryogenic tube (18) on the left in the figure, and the other is to follow the cryogenic tube ( 18) Use the connecting joint (26) to connect; the inner side of the upper part of the cylinder (5) is welded with a guide tube clamp (23) that clamps the guide tube (22); the cross bar (19) is placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com