On-line detection method of shut-off valve leakage rate

A detection method and shut-off valve technology, which are applied in the direction of measuring the acceleration and deceleration rate of the fluid, using the liquid/vacuum degree for liquid tightness measurement, etc. and other problems, to achieve the effect of fast positioning speed, improving verification work efficiency, and solving long detection time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

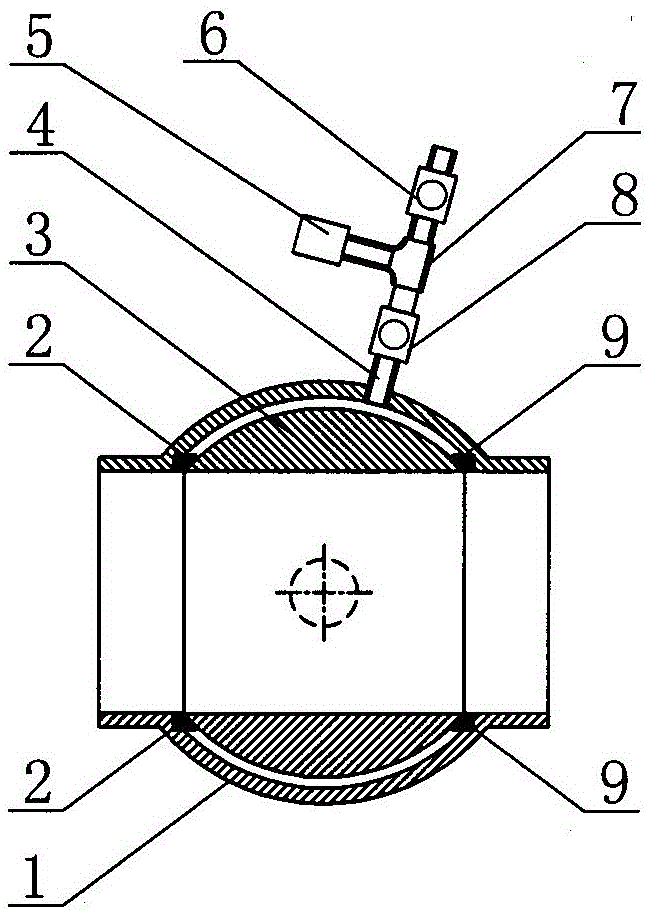

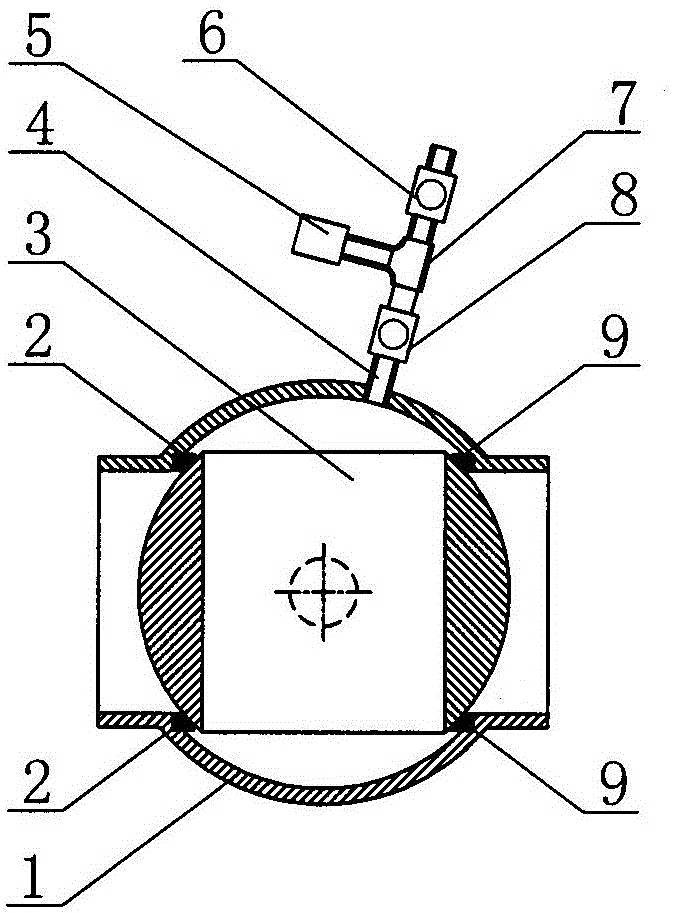

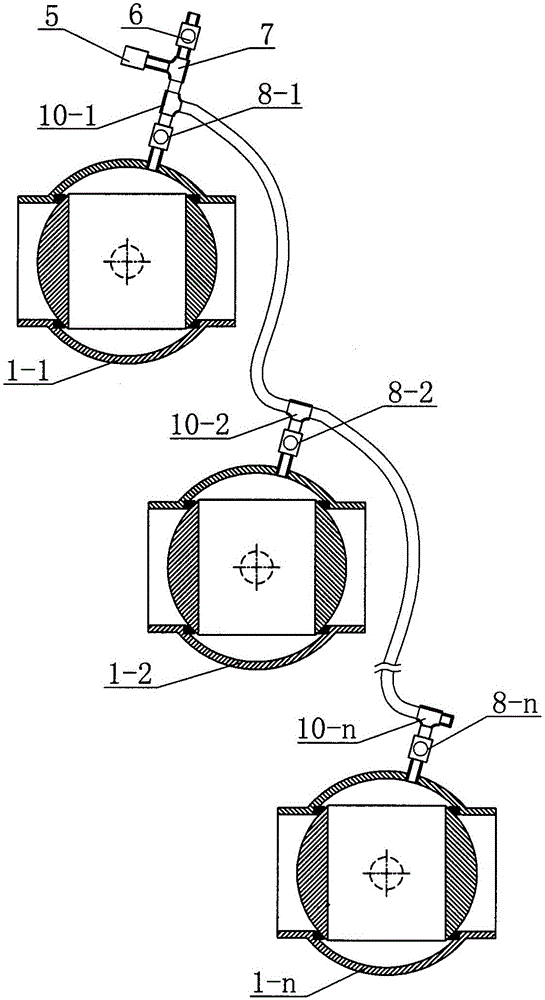

[0016] according to Figure 1~3 The specific structure of the present invention will be described in detail. The shut-off valve leak rate on-line detection device used in the cut-off valve leak rate on-line detection method includes a valve body 1 connected with a pressure measuring inlet pipeline and an outlet pipeline, and is packaged in the valve body 1 through an inlet sealing ring 2 and an outlet sealing ring 9 The spool 3, the interface valve 8, the pressure measuring part 5 and the pressure relief valve 6, and connecting pipes and other components. Valve body 1, valve core 3 and inlet and outlet sealing rings 2, 9 form a closed cavity, which is used as a leak rate cavity, and the volume of the cavity and connecting pipe can be calibrated by liquid.

[0017] The valve body 1 includes an interface mechanism connected to the inlet and outlet pipelines and a rotating mechanism (not shown in the figure) that controls the action of the valve core 3, and its specification and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com