Device and method for measuring refractive index of flat plate type transparent medium

A technology of transparent medium and measuring plate, applied in the direction of phase influence characteristic measurement, etc., can solve the problems of difficult operation, cumbersome operation, high requirements of experimental conditions, etc., and achieve the effect of low cost, high measurement accuracy and high definition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

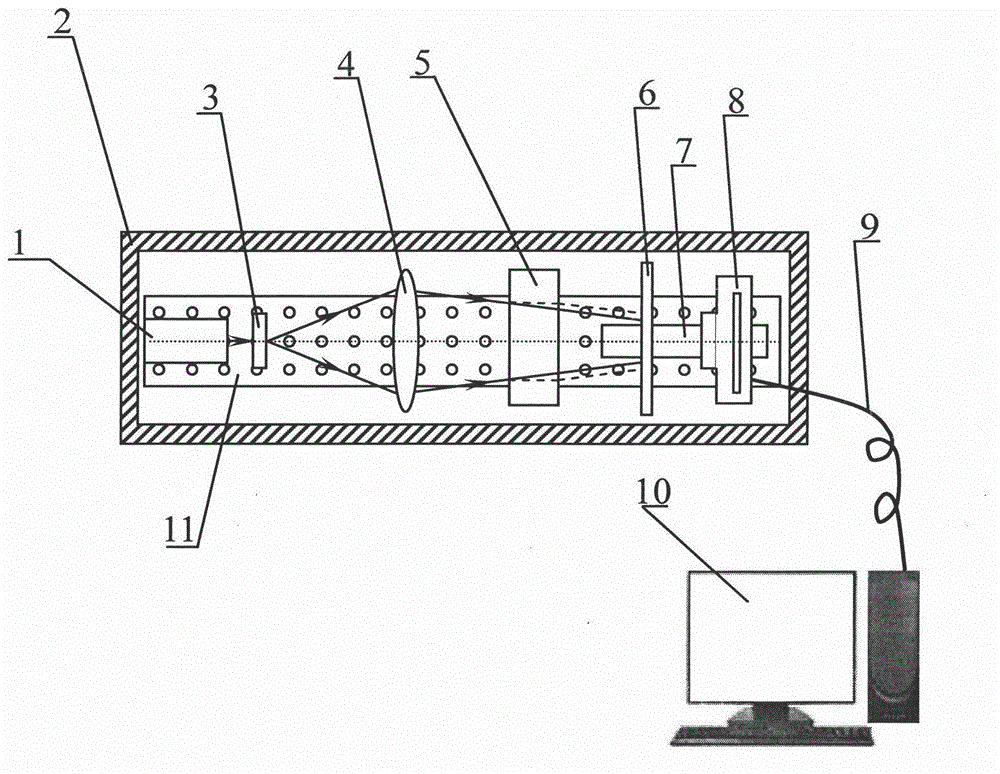

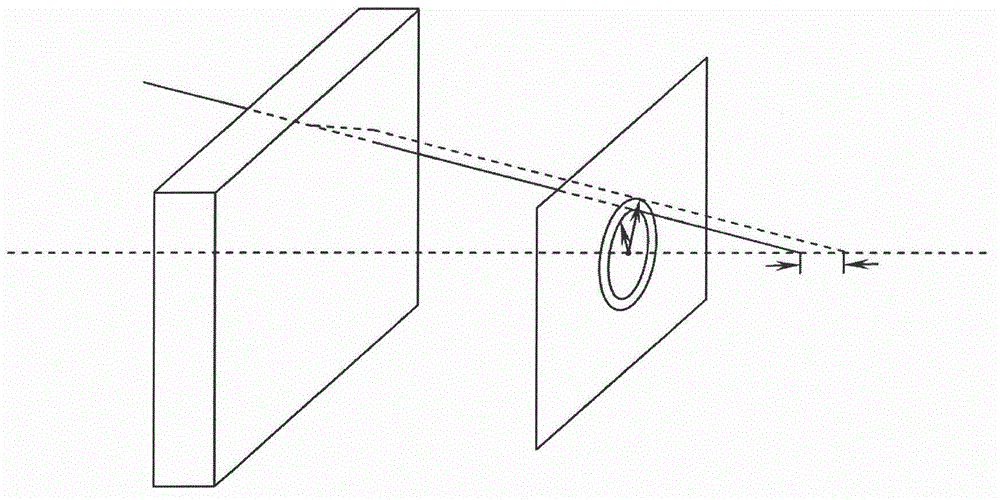

[0021] exist figure 1 Among them, the flat plate type transparent medium refractive index measuring device of the present embodiment is made up of semiconductor laser 1, cassette 2, frosted glass screen 3, converging lens 4, thin ground glass screen 6, small precision translation stage 7, CCD camera 8, computer 10, to be The measuring medium 5 is placed between the converging lens 4 and the precision translation stage 7, a platform liner 11 with screw holes is provided at the bottom of the cassette, and a light-shielding cover is provided at the top.

[0022] The housing of the cassette 2 in this embodiment is made of stainless steel or opaque engineering plastics, the bottom of the cassette 2 is centered with a steel platform liner 11 with screw holes, and the left end of the cassette 2 fixes the semiconductor laser 1 with connectors such as screws and brackets. Installed on the platform liner 11, the ground glass screen 3 and the converging lens 4 on the right side of the s...

Embodiment 2

[0032] In this example, add Figure 4 The rectangular parallelepiped liquid tank is open at the top, the bottom is frosted glass, the left and right sides are flat glass used as optical surfaces, and the front two sides are frosted glass. The connection relationship of other constitutions and components is the same as that of Embodiment 1.

[0033] The method for measuring distilled water at room temperature using the flat-plate transparent medium refractive index measuring device of this embodiment is as follows:

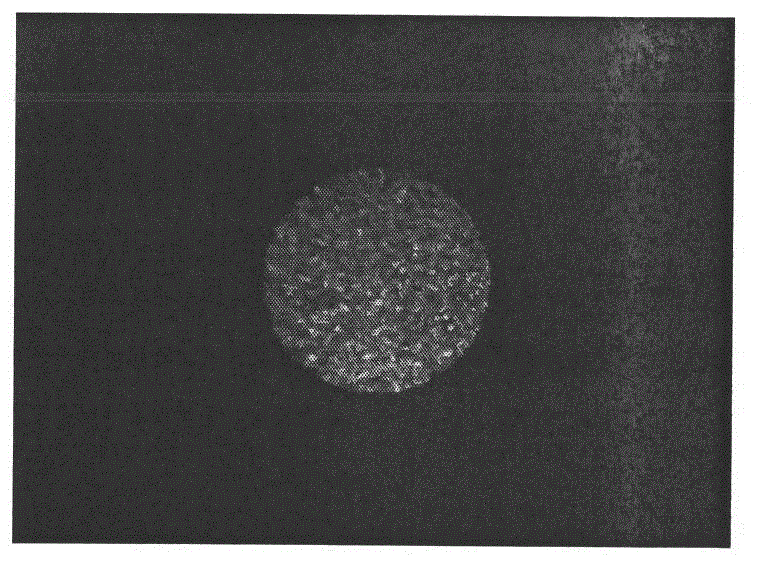

[0034] 1. Turn on the power supply of the semiconductor laser 1, the emitted light passes through the ground glass screen 3 to form a relatively uniform speckle, and a uniform circular light spot is obtained on the thin ground glass screen 6 through the converging lens 4, and the image is obtained by the computer 10 through the CCD camera 8 .

[0035] 2. Calibration: First measure the width T in the cuboid open liquid tank, and input it into the computer 10, then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com