Thermoelectric conversion module and method of manufacturing thereof

A thermoelectric conversion and manufacturing method technology, applied in the manufacture/processing of thermoelectric devices, thermoelectric device components, thermoelectric devices that only use the Peltier or Seebeck effect, etc., can solve the problem of smaller temperature difference, lower power generation capacity, and low thermal conductivity and other issues to achieve the effect of high reliability and high power generation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

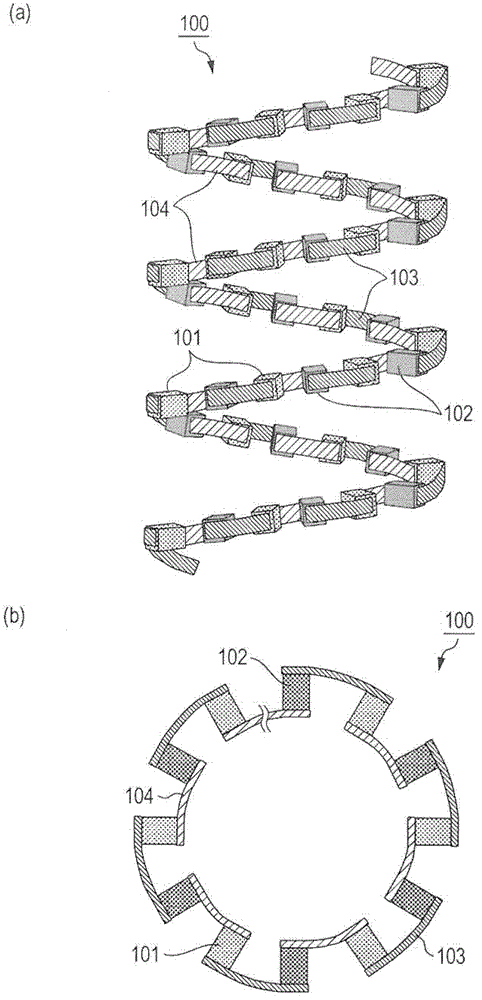

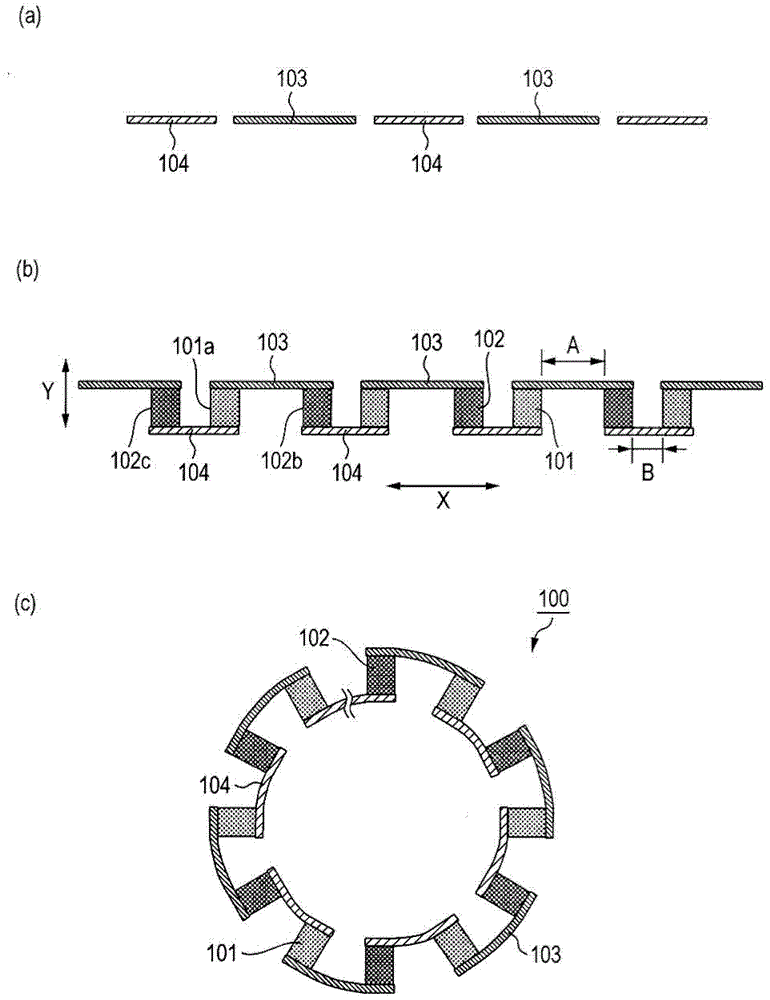

[0093] figure 1 is a schematic diagram of the thermoelectric conversion module 100 according to the first embodiment of the present invention. figure 1 (a) is a perspective view of the thermoelectric conversion module 100, figure 1 (b) is a top view of the thermoelectric conversion module 100 .

[0094] 1. The structure of the thermoelectric conversion module:

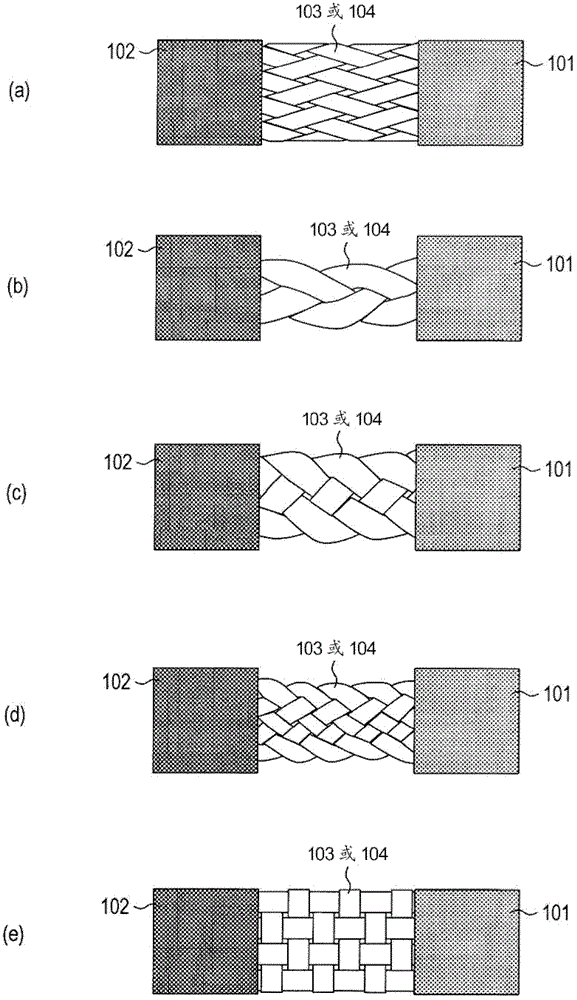

[0095] The thermoelectric conversion module 100 in this embodiment is basically composed of a P-type thermoelectric conversion element 101 , an N-type thermoelectric conversion element 102 , a braided wire 103 , and a braided wire 104 . The braided wire 103 corresponds to the braided wire A. The braided wire 104 corresponds to the braided wire B. Additionally, along the figure 1 P-type thermoelectric conversion elements 101 and N-type thermoelectric conversion elements 102 are alternately arranged sequentially in the circumferential direction of the spiral shape shown. At this time, if figure 1 As shown, on...

Embodiment approach 2

[0121] Next, a second embodiment of the present invention will be described with reference to the drawings.

[0122] Figure 5 It is a perspective view showing a schematic configuration of a thermoelectric conversion module 200 according to Embodiment 2 of the present invention. The thermoelectric conversion module 200 is basically composed of a P-type thermoelectric conversion element 101 , an N-type thermoelectric conversion element 102 , braided wires 103 , braided wires 104 , and electric wires 105 .

[0123] The adjacent P-type thermoelectric conversion elements 101 and N-type thermoelectric conversion elements 102 are electrically connected alternately and in series by braided wires 103 and braided wires 104 . Braided wire 103 is bonded to the upper surface of P-type thermoelectric conversion element 101 and the upper surface of N-type thermoelectric conversion element 102 . Braided wire 104 is bonded to the surface (lower surface) of P-type thermoelectric conversion e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com