Resin/metal composite laminate material, resin/metal composite injection moulding body, and manufacturing method for same

A metal composite, laminated material technology, applied in metal layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve the problems of thinning limitation, poor waterproofness, constraints, etc., and achieve excellent press processability, The effect of high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0194] [Examples 1-4, Comparative Examples 1-3]

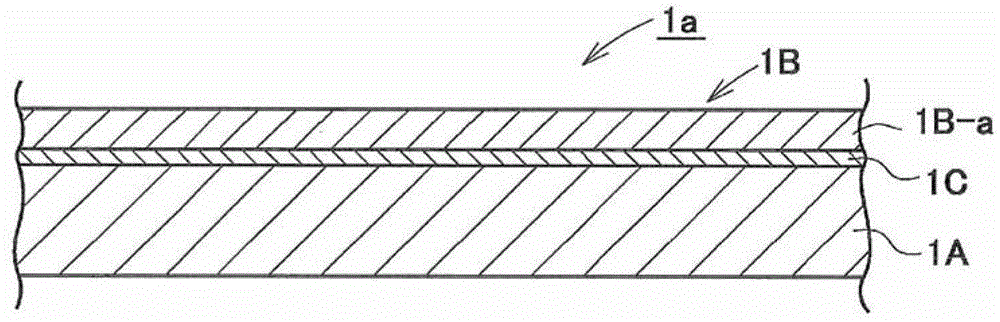

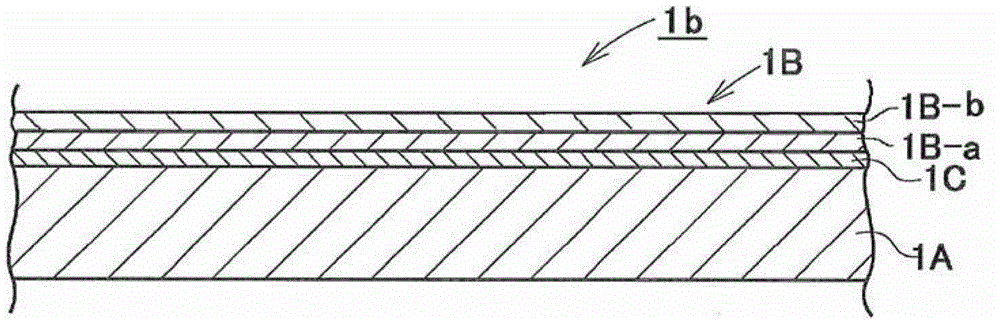

[0195] A base layer with a thickness of 1 μm was formed after coating a bisphenol A type epoxy resin on one side of a stainless steel plate (SUS3041 / 2H thickness 0.3 mm).

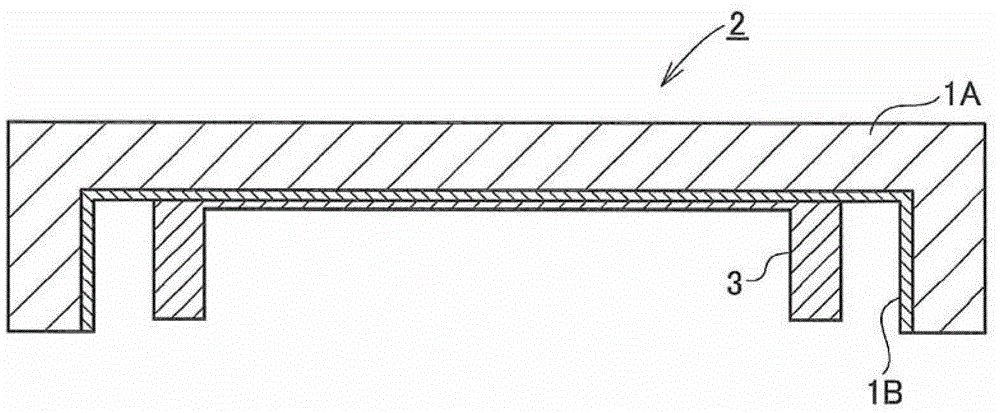

[0196] Next, follow image 3 In the method shown, a nylon 6 film (manufactured by Mitsubishi Plastics Co., Ltd., melting point: 220° C.) was laminated on the base layer forming surface of the stainless steel plate to obtain a resin / metal composite laminate.

[0197]During lamination, the heating temperature in the heating furnace 24 is set to 350°C, and the reheating temperature, cooling method, and reheating time of the reheating furnace 28 are set as shown in Table 1, thereby forming The crystallinity of the resin layer changes. In addition, the thickness of the formed resin layer (resin layer a) was all 25 micrometers.

[0198] It should be noted that for Examples 3 and 4, samples were produced under the same conditions as in Example 1, and only the me...

reference example 1

[0212] A nylon 66 resin ("CM3001-N" manufactured by Toray, melting point: 265° C.) was melted between two heating rolls to obtain a nylon 66 film having a thickness of 25 μm.

[0213] Using the nylon 66 film instead of the nylon 6 film, a resin layer was formed on the surface of the stainless steel plate in the same procedure as in Example 1 to obtain a resin / metal composite laminate.

[0214] Using this resin / metal composite laminate, a sample for a tensile test was produced in the same manner as in Example 1, and the tensile test was performed in the same manner. Table 2 shows the results.

reference example 2

[0216] The stainless steel plate used in Example 1 was heated to 100°C, and a commercially available nitrile rubber thermocompression adhesive tape (manufactured by Tesa tape, softening point 100°C) was welded to form a resin layer with a thickness of 38 μm, thereby obtaining a resin / Metal composite laminates.

[0217] Using this resin / metal composite laminate, a sample for a tensile test was produced in the same manner as in Example 1, and the tensile test was performed in the same manner. Table 2 shows the results.

[0218] It should be noted that whether or not the resin (resin of the resin layer of the resin / metal composite laminated material) in each example adheres to the injection mold during injection molding (with (○) or without (×)) is also included. Recorded in Table 2.

[0219]

[0220] From the above results, it can be seen that the resin / metal composite laminated material of the present invention having a polyamide-based resin layer having a crystallization ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com