Generator assembly for a wind power plant

A technology for wind energy equipment and generators, applied in wind energy power generation, wind turbine components, electromechanical devices, etc., can solve the problems of wear, complex mutual support of transmission components and generator components, etc., to shorten the path of the force line and simplify assembly. and the effect of disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

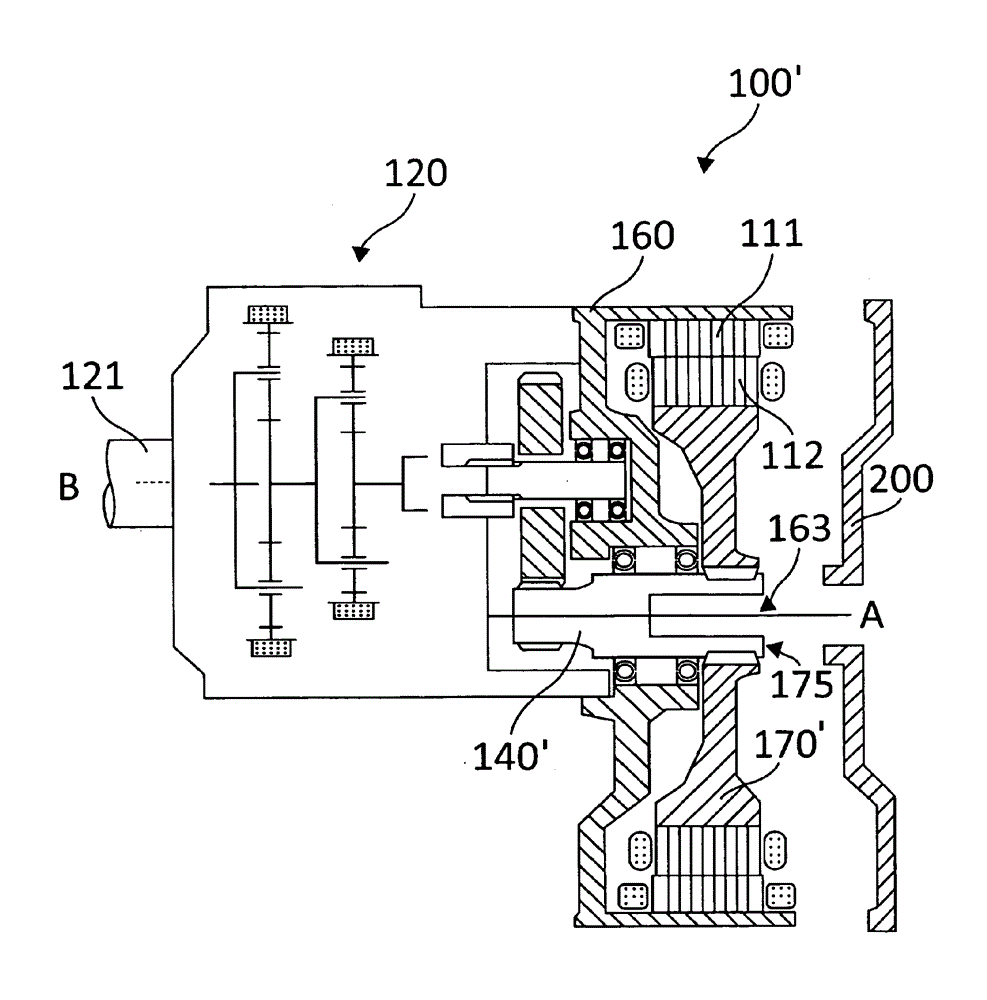

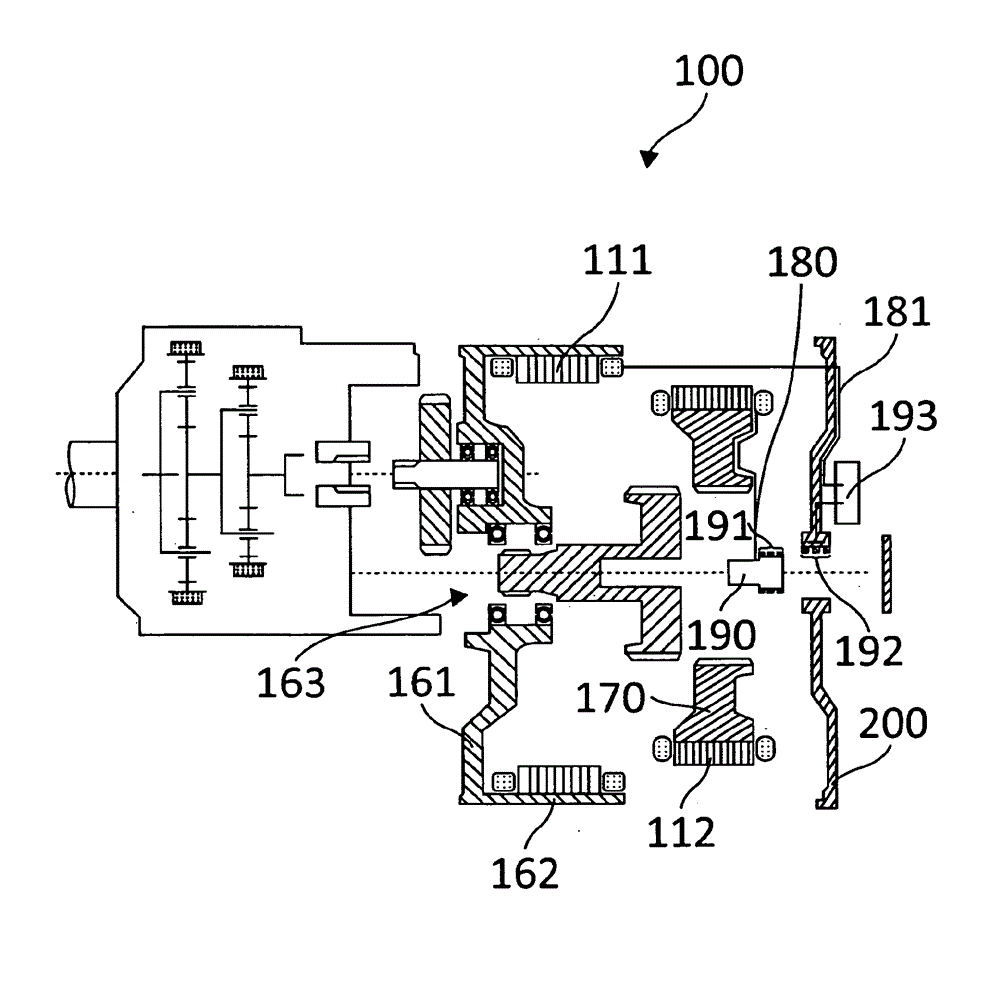

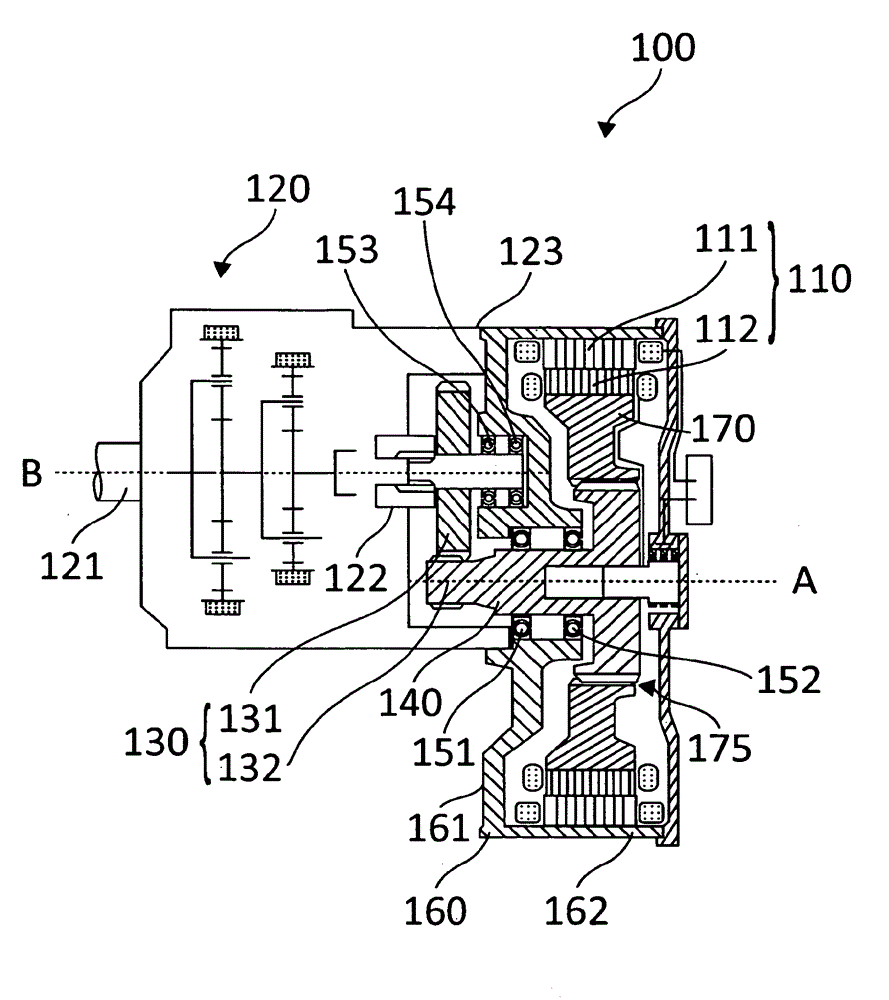

[0021] on the one hand figure 1 and figure 2 and on the other hand in image 3 Various embodiments of the generator arrangement according to the invention are shown in the figure, but these are described below mainly to the extent that they contain identical or identically acting elements. These elements are provided with the same reference numerals.

[0022] exist figure 1 and figure 2 In , a first preferred embodiment of the generator arrangement according to the invention is shown schematically in cross-section and is indicated overall by 100 . The generator arrangement 100 comprises a doubly-fed asynchronous generator 110 with a stator 111 containing a coil arrangement and a rotor 112 containing a coil arrangement, the winding ends of which are also drawn beside each other on the right and left . The rotor 112 is mounted rotatably about an axis A of rotation.

[0023] The generator arrangement has a base frame component 160 which at the same time serves as a housi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com