Ultrasonic Mutagenesis Breeding Device

A technology of mutation breeding and ultrasound, applied in the fields of seed and rhizome treatment, plant genetic improvement, botany equipment and methods, etc., can solve the problems that plant seeds cannot receive uniform ultrasonic radiation, lack of lateral movement, etc., and achieve novel structure and shorter The effect of germination cycle and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

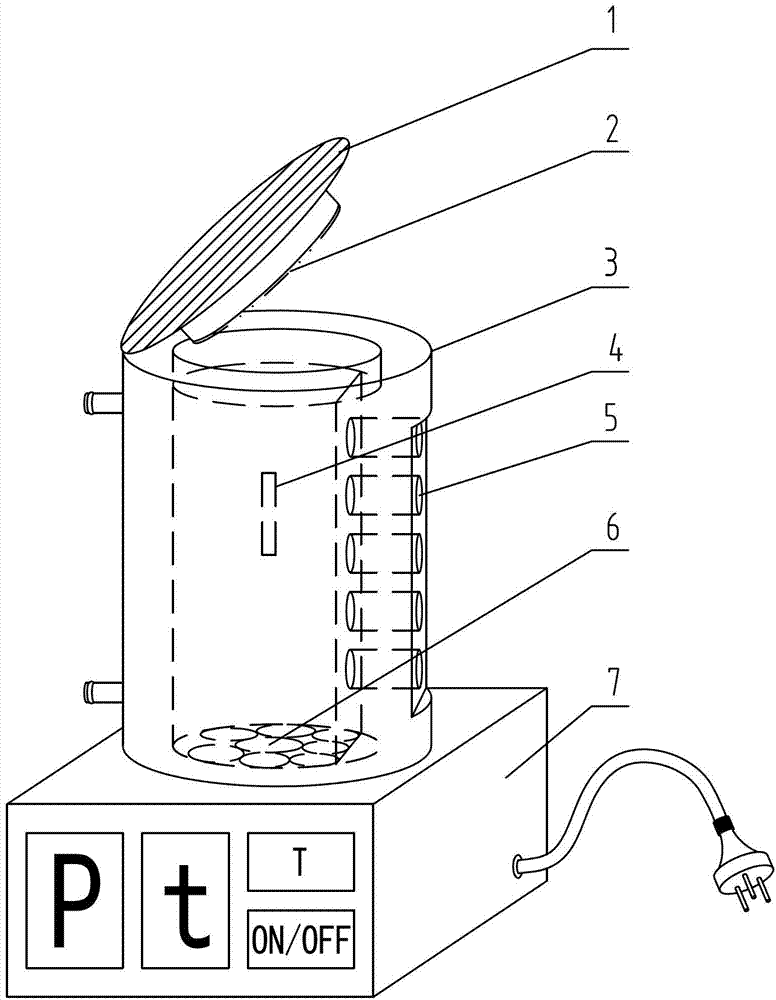

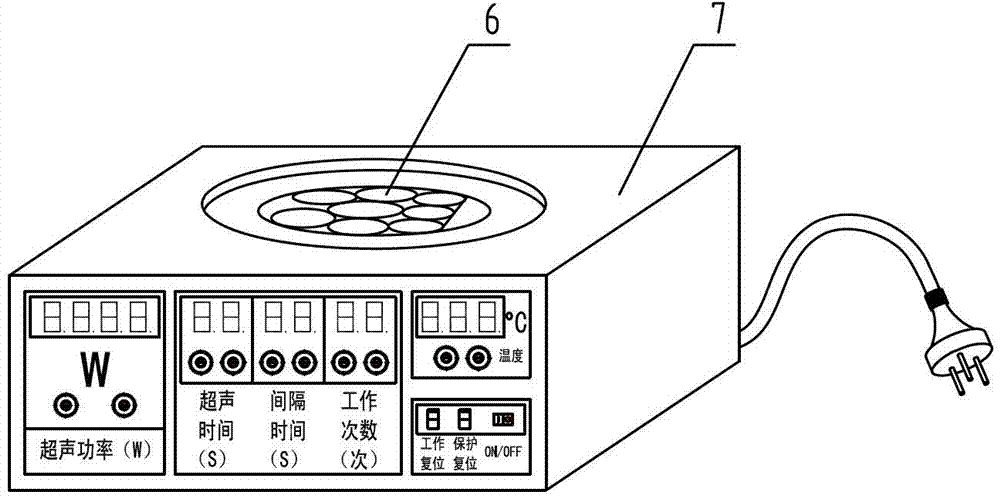

[0022] see figure 1 , The ultrasonic mutagenic breeding device of the present embodiment is composed of a container cover 1, a sound-absorbing layer 2, a reaction vessel body 3, a temperature sensor 4, a transverse ultrasonic transducer group 5, a longitudinal ultrasonic transducer group 6, and a base 7.

[0023] see figure 2 , the base 7 in this embodiment is the breeding device base 7 in the conventional design, a circular groove is arranged on the top of the housing of the base 7, and a longitudinal ultrasonic wave composed of 8 longitudinal ultrasonic transducers connected in parallel is installed in the groove. Transducer group 6, the ultrasonic frequency of the longitudinal ultrasonic transducer group 6 is 10000Hz, the power is 1W, the longitudinal ultrasonic transducers are evenly distributed in the groove, and the installation direction of each transverse ultrasonic transducer is kept positive pay. A card slot is processed on the side edge of the groove.

[0024] A...

Embodiment 2

[0028] In the above-mentioned embodiment 1, the sulfur-free rubber wedge sound-absorbing layer 2 is provided on the inner wall of the reaction vessel body 3 and the inner side of the vessel cover 1 . The transverse ultrasonic transducer group 5 is composed of two transverse ultrasonic transducer groups 5 , and the longitudinal ultrasonic transducer group 6 is composed of two longitudinal ultrasonic transducer groups 6 . The ultrasonic frequency of the transverse ultrasonic transducer group 5 and the longitudinal ultrasonic transducer group 6 are both 10KHz, and the power is 1W. The other components and their connections and working principles are the same as those in Embodiment 1.

Embodiment 3

[0030] In the above-mentioned embodiment 1, the cavity wedge sound-absorbing layer 2 is provided on the inner wall of the reaction vessel body 3 and the inner side of the vessel cover 1 . The transverse ultrasonic transducer group 5 is composed of 8 transverse ultrasonic transducer groups 5 , and the longitudinal ultrasonic transducer group 6 is composed of 5 longitudinal ultrasonic transducer groups 6 . Other components and their connection relations and working principles are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com