Method for continuous jet descaling

A technology of jet and jet nozzle, which is applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of inability to effectively remove hard particle embedding, low processing stability, and unclean surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

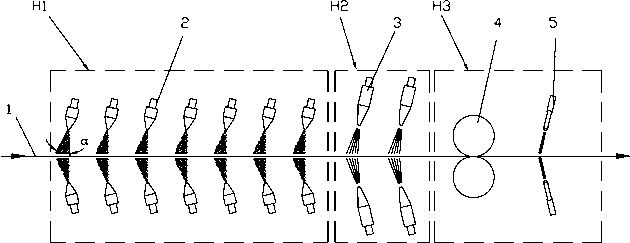

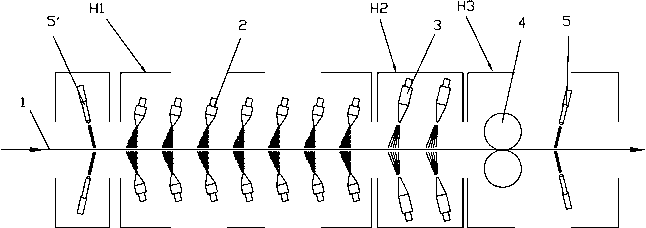

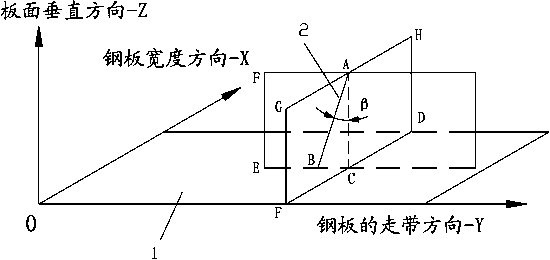

[0031] see figure 1 , the steel billet is coiled after being divided into coils by the hot rolling mill, and then needs to be continuously descaled before entering the cold rolling mill. That is, before the steel plate enters the jet descaling section H1, it becomes a continuous steel plate 1 (metal strip) with an infinite length, and its temperature is not higher than 200°C. At the descaling unit H1, at this time, the jet nozzle 2 in the jet descaling unit H1 starts to spray a mixed jet with a pressure of 50 MPa and 80 mesh garnet containing 15% of the mass ratio. The uniform distribution of the spray intensity on the steel plate 1 enables the uniform peeling and loosening of scales on the surface of the steel plate 1 .

[0032] After the steel plate 1 comes out of the high-pressure jet descaling section H1, it immediately enters the high-pressure water cleaning section H2. The high-pressure water cleaning section H2 uses the high-pressure pure water nozzles 3 uniformly arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com