Chamfering blade with staggered teeth

A technology of staggered teeth and chamfering, applied to gear teeth, components with teeth, gear tooth manufacturing tools, etc., can solve problems such as single function, less open chamfering tools, and no chamfering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Further illustrate by the following examples.

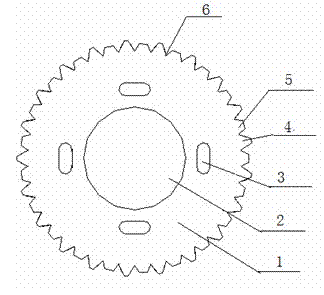

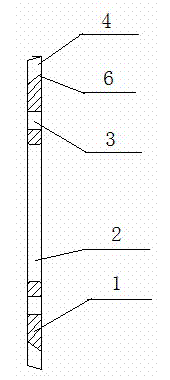

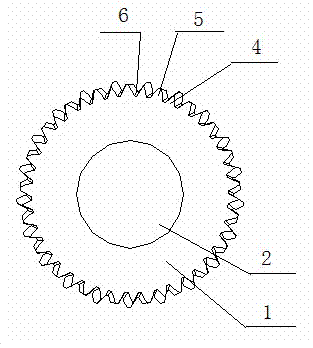

[0015] The cutter body 1 is circular, and there is a shaft hole 2 in the middle of the cutter body 1, and waist-shaped grooves 3 are evenly distributed around the shaft hole 2. 5 with alveolar 6.

[0016] The cutter teeth 4 and the staggered teeth 5 have different shapes, or different heights, or different thicknesses, or different phases, or different axial positions.

[0017] In the present invention, the tool is a complete single blade part, but multi-functional chamfering is realized on the same chamfering knife, and one set of cutter teeth 4 is combined with more than one set of staggered teeth 5, that is, there are 2 sets or 2 sets on the outer circle For the above different combinations of cutter teeth 4 and offset teeth 5, the arrangement of cutter teeth 4 and offset teeth 5 is mutually staggered, and the design of each set of teeth needs to realize its own function, corresponding to a specific function re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com