Bonding device for polymer microfluidic chip

A microfluidic chip and bonding device technology, applied in the controllable bonding equipment and precision fields, can solve the problems of poor mask versatility, high cost, complex manufacturing process, etc., and achieve precise positioning, high-precision temperature monitoring and Control and realize the effect of automatic self-locking and clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

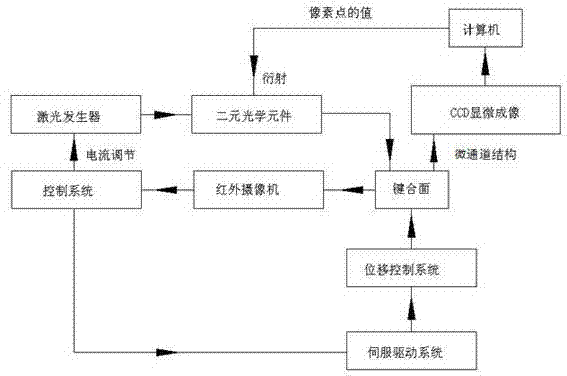

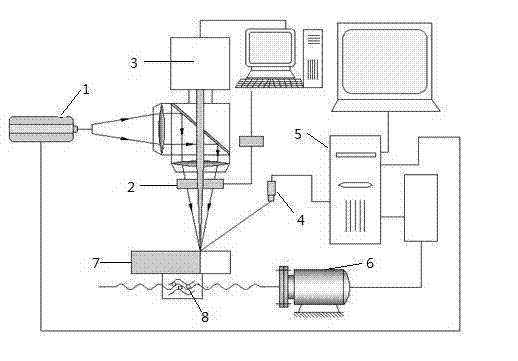

[0025] Embodiment 1: A polymer microfluidic chip bonding device, including a laser generator, a controllable optical system containing a liquid crystal mode micro-optical device, an image recognition and image processing system, an online real-time temperature monitoring and control system, and a precision displacement Control platform, servo drive system and control system.

[0026]

[0027] See attached figure 1 As shown, in the controllable optical system, there is a binary optical element 2 in liquid crystal mode, and the laser beam is diffracted by the binary optical element 2 at the chip to be bonded on the displacement control platform 7; the image recognition and processing The system includes a CCD3 and a computer, and the size and intensity of the light spot can be flexibly controlled by the computer processing the diffraction image collected by the CCD3.

[0028] The temperature online real-time monitoring and control system includes an infrared camera 4 with a wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com