Measuring method for encapsulating agent in porous granular ammonium nitrate

A technology of granular ammonium nitrate and a determination method is applied in the field of determining the content of encapsulant in porous granular ammonium nitrate by gravimetric method after liquid separation, and can solve the problems of long reflux time, complicated operation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Accurately weigh 100g of the sample, place it in a 100mL beaker, add 60°C desalted water, place it on an electric heating plate with a preset temperature of 60°C, stir while heating until it is completely dissolved, then pour the solution into a 250mL conical in a separatory funnel. Rinse the beaker with 60°C water for 2-3 times, and pour the rinse solution into the separatory funnel. Place the separatory funnel on the iron ring of the iron stand and let it stand for 10 minutes to separate the aqueous solution and oil. Slowly drain the aqueous solution in the lower layer of the separatory funnel, and the insoluble part adheres to the inner wall of the separatory funnel. Rinse the funnel with 60°C water and repeat the operation 2 times. Place the previously constant weight weighing bottle under the end of the separatory funnel, add acetone with a dropper to clean the inner wall of the separatory funnel until it is clean.

[0015] Heat the weighing bottle in a water ba...

Embodiment 2

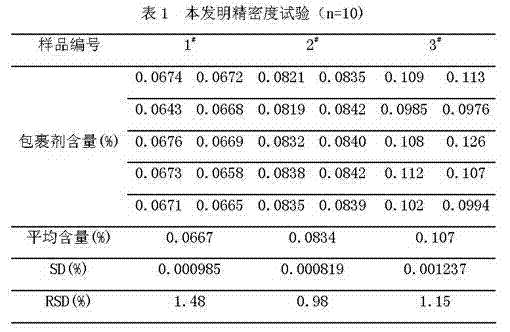

[0017] Get 3 samples, parallel test 10 times respectively, the precision test result of the present invention is shown in Table 1.

[0018]

[0019] Relevant data show that when the coating agent content in the sample is 0.06%-0.13%, the relative standard deviation measured by the prior art method is 5.63%-11%. As can be seen from Table 1, the relative standard deviation of the test of the present invention is obviously better than the prior art method.

Embodiment 3

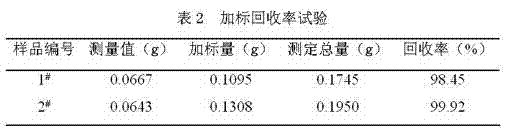

[0021] The sample was measured according to the test method of Example 1, and a certain standard amount of coating agent was added at the same time, and the measurement was performed again, and the recovery rate was shown in Table 2.

[0022]

[0023] It can be seen from Table 2 that the recoveries reached 98.45% and 99.92%, and the accuracy of the method met the requirements.

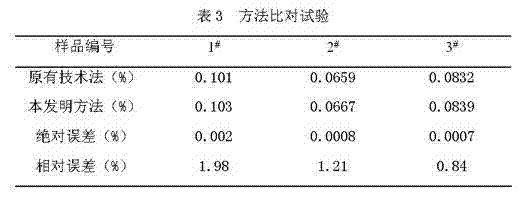

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com