Method for predicting faults in cascade polymerization reaction process of high density polyethylene (HDPE)

A high-density polyethylene, cascade polymerization technology, applied in the application of electromagnetic flowmeter to detect fluid flow, thermometer, measure heat and other directions, can solve the problems of complex process structure, waste loss, affecting the production efficiency of enterprises, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

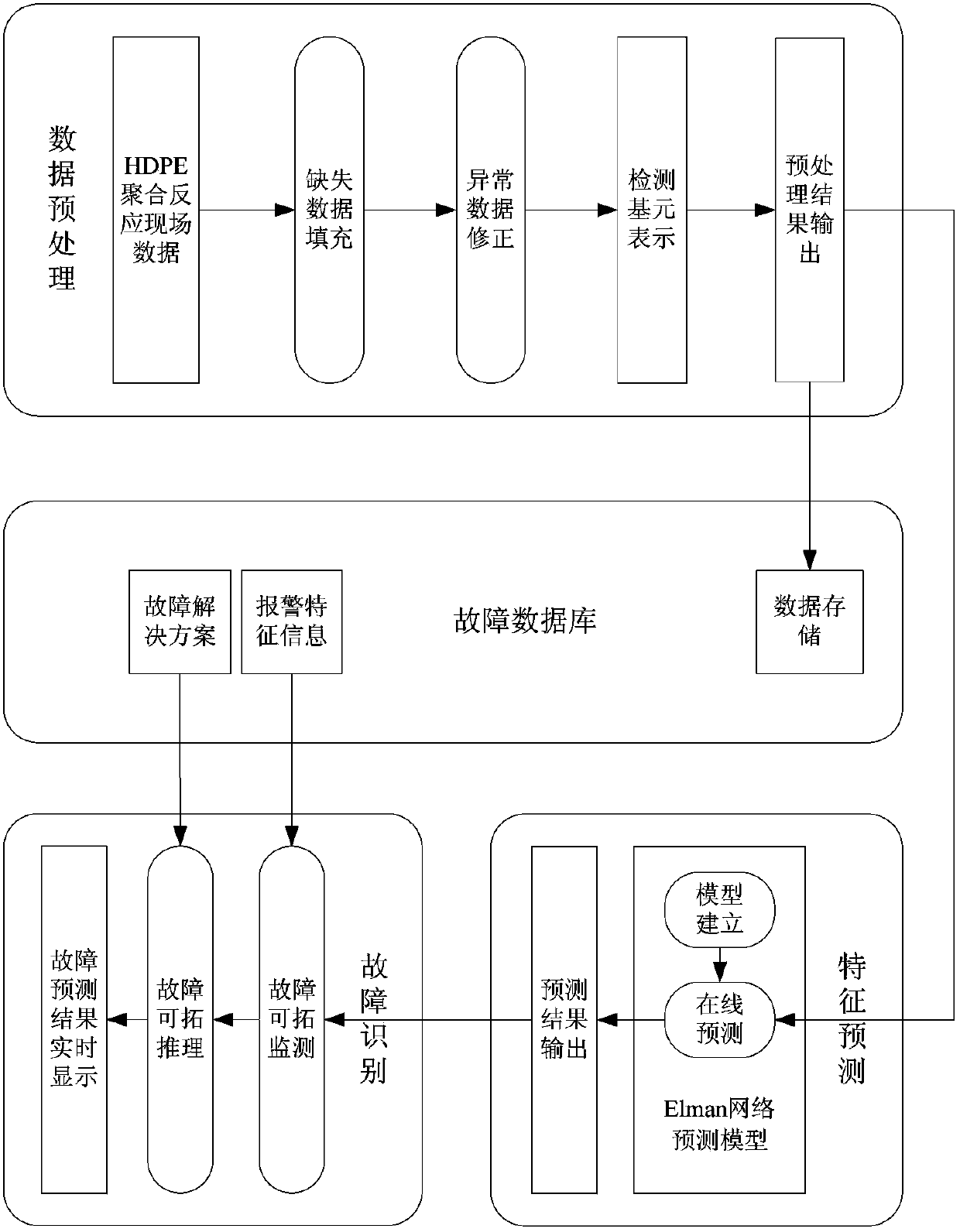

AI Technical Summary

Problems solved by technology

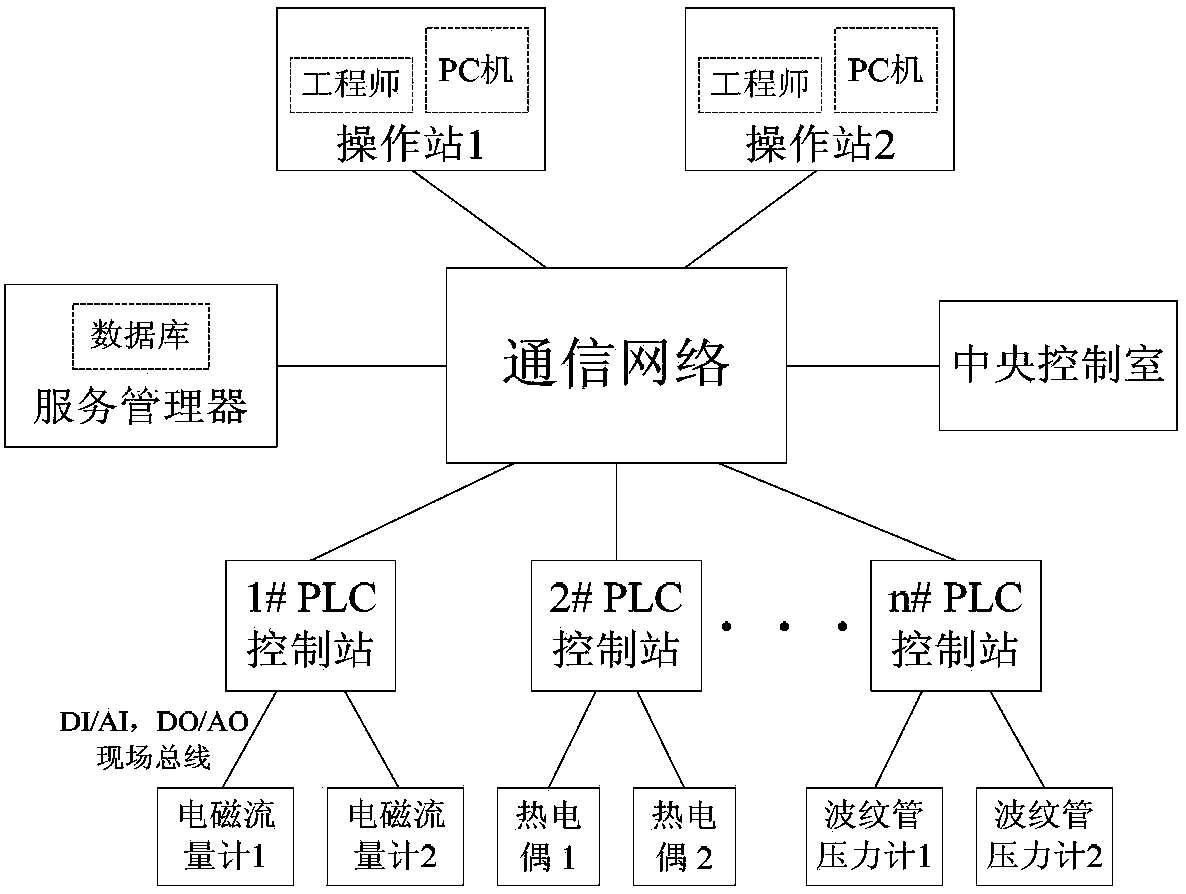

Method used

Image

Examples

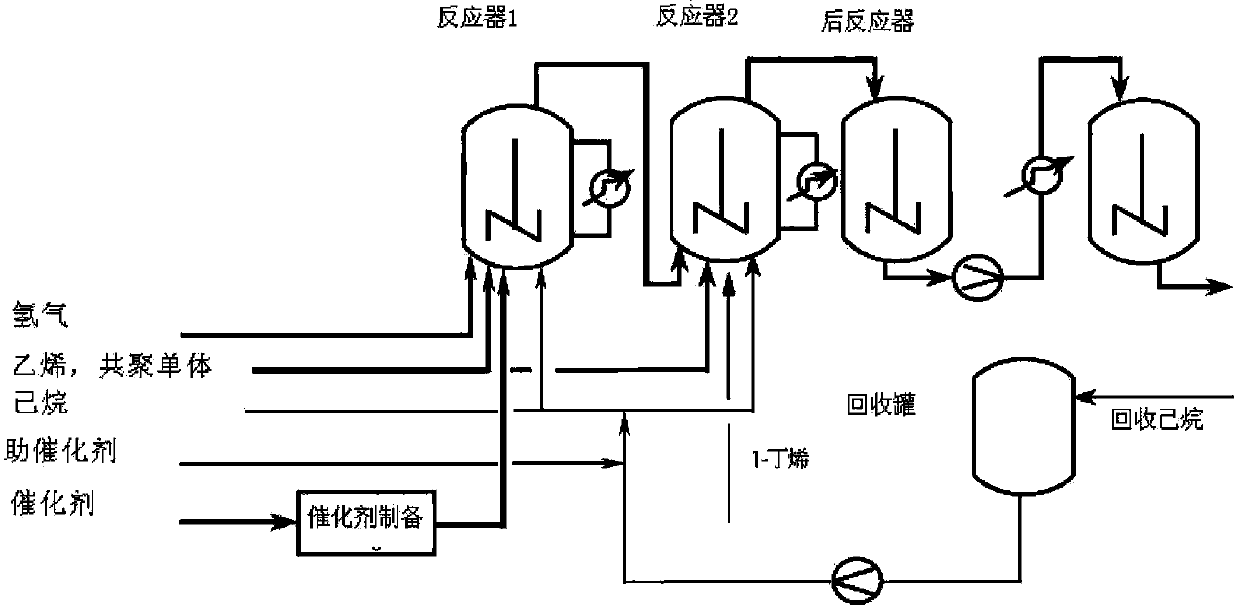

Embodiment Construction

[0229] As shown in Table 1, it is a list of all detection primitives that affect the quality indicators of polyethylene products. The specifications of polyethylene products in the industry are mainly distinguished according to the melt index MI (Melt Index) and the density ρ (Density), in which, because the density of the polymer is through the feed between ethylene and the comonomer 1-butene monomer The comonomer is only added in the second reactor to adjust the polymer density, so the product density in the first reactor is not considered as a reaction characteristic parameter, that is to say, a reactor melt index MI 1 , Melt index MI of the second reactor 2 And the second reactor density ρ is the main parameter reflecting the product quality of polyethylene production. Through the analysis of material balance and energy balance in the HDPE reaction process, the weakly correlated nodes are eliminated from all the detection nodes of the HDPE device, and each detection varia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com