Optical filter

A technology of optical filter and optical film, which is applied in the direction of optics, optical components, chemical instruments and methods, etc., can solve problems such as reducing volume and weight, reducing aberration, and reducing thickness, so as to improve production efficiency and price Expensive, the effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

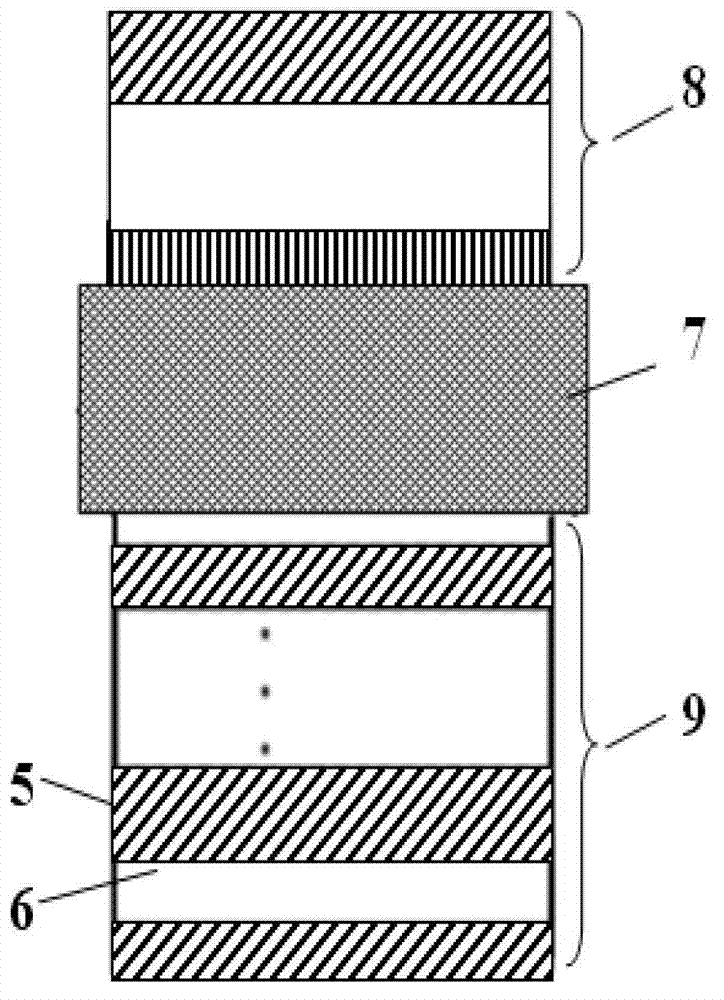

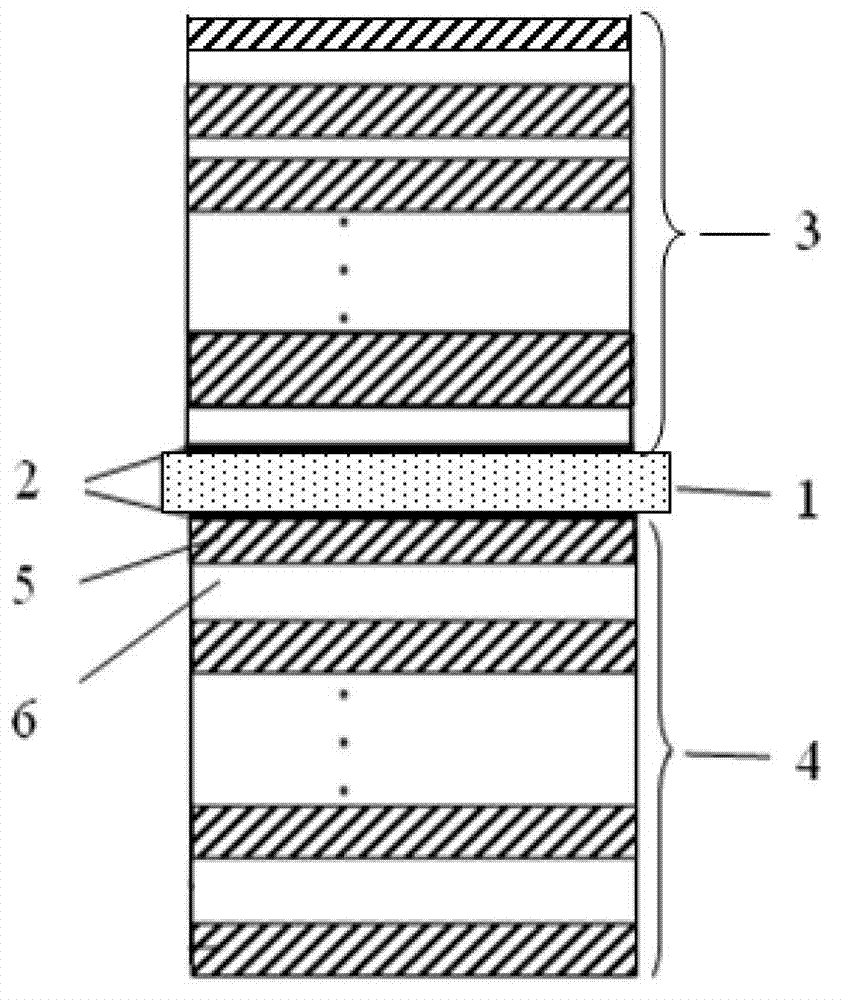

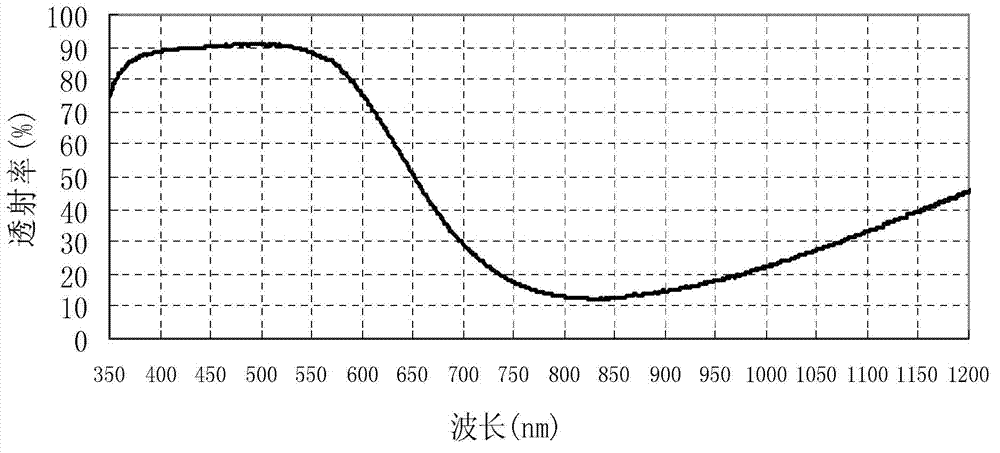

[0025] figure 1 Shown is a schematic structural view of an optical filter using blue glass in the prior art, including a blue glass substrate 7, an antireflection film 8 arranged on one side of the blue glass substrate 7, and an antireflection film 8 arranged on the other side of the blue glass substrate 7. The existing infrared-ultraviolet filter film 9, the thickness of the blue glass substrate 7 needs about 0.5mm to obtain the steepness of the transmission-cut-off transition region that barely meets the requirements. Although this has caused the problem of increased aberration, the benefits It is to reduce the deformation of the blue glass substrate 7 caused by the film stress, and the two surfaces of the blue glass substrate 7 are usually coated with an anti-reflection film 8 and an existing infrared-ultraviolet filter film 9, and the anti-reflection film 8 is A three-layer film composed of three materials is usually required. The existing infrared-ultraviolet filter film ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com