System and method for actively correcting offset drift and wire bonder

A wire bonding machine and biasing technology, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of low measurement accuracy and sensitivity, complex system structure, and difficult installation, and achieve simple structure, Ensure the effect of welding precision and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

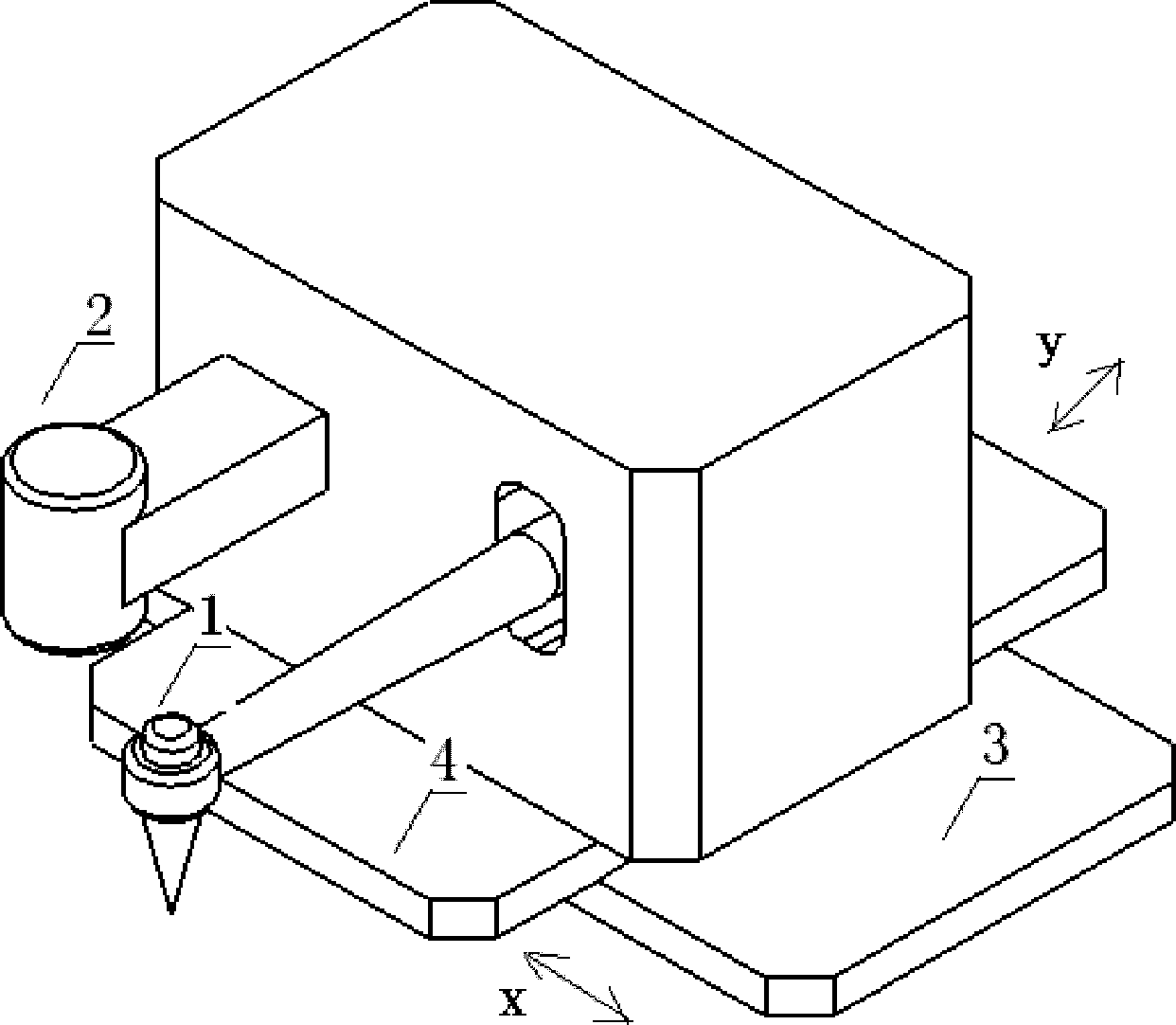

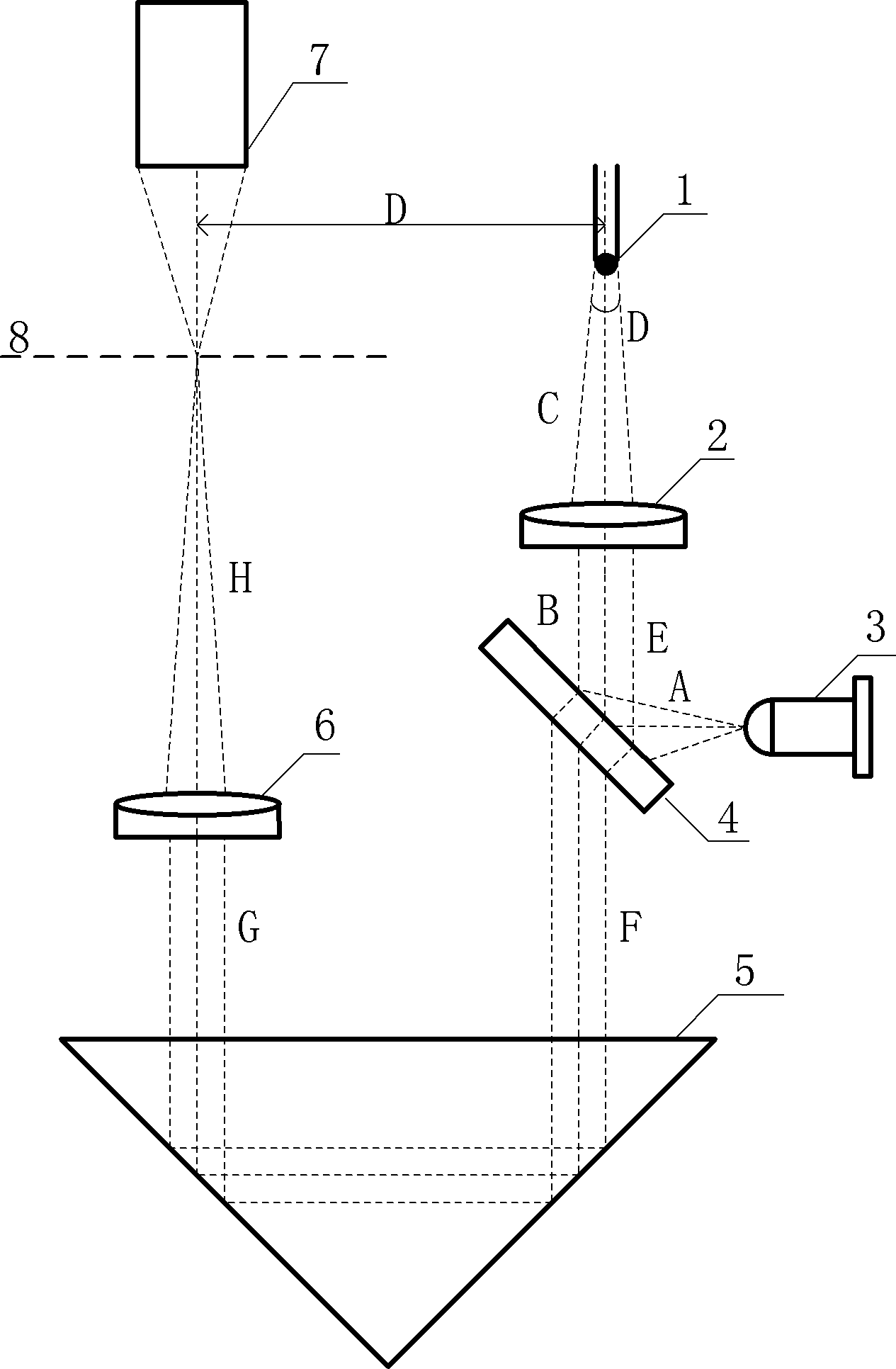

[0046] The embodiment of the present invention provides an active correction system for offset drift, which is installed on the semiconductor post-packaging equipment - wire bonder (Wire bonder), and is used to measure the temperature of the bonding head and other random errors of the system The distance between the capillary and the imaging system (that is, the optical system) in the wire bonding machine caused by the figure 2 D in ) indicates offset drift, and the distance parameter between the capillary and the imaging system is corrected, so that the wire bonding machine uses the current correct distance parameter between the capillary and the imaging system for welding.

[0047] The bias drift active correction system provided by the embodiments of the present invention can realize precise, high-speed, and stable chip bonding or real-time measurement of the bias drift of the imaging system and the chopper during bonding. The specific implementation of the system can be a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com