Water-based conducting resin for lithium ion battery

A technology of lithium-ion batteries and conductive adhesives, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of increasing battery costs, affecting the number of charge and discharge, and affecting the insertion and extraction of lithium ions, so as to achieve easy insertion and extraction, The effect of high charge and discharge times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The conductive adhesive is prepared according to the following composition ratio (mass percentage content):

[0014] Octahydroxyquinoline 5%,

[0015] Graphite 37%,

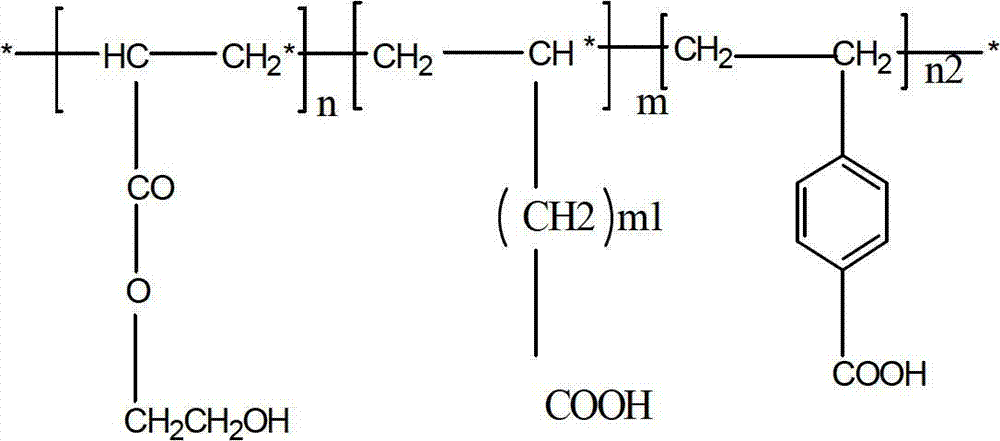

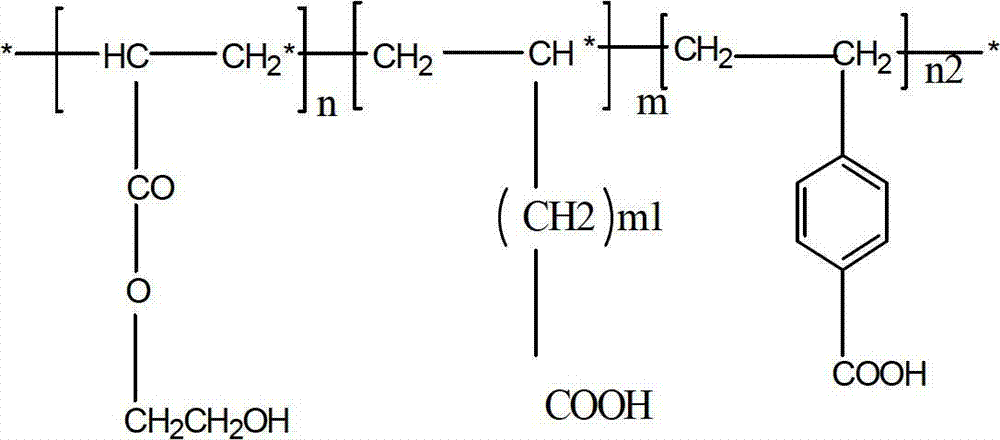

[0016] Acrylic copolymer 30%,

[0017] Linseed oil 1%,

[0018] Isopropanol 5%,

[0019] KH560 2%,

[0020] Water 20%.

[0021] The preparation method is to firstly mix the liquid components in the technical formula components evenly, then add the solid components and stir evenly, then grind on a grinder, and finally pack.

Embodiment 2

[0024] The conductive adhesive is prepared according to the following composition ratio (mass percentage content):

[0025] Octahydroxyquinoline 5%,

[0026] Graphite 25%,

[0027] Acrylic copolymer 30%,

[0028] Linseed oil 3%,

[0029] Isopropanol 12%,

[0030] KH560 5%,

[0031] Water 20%.

[0032] The preparation method is the same as in Example 1.

[0033] The effect of the embodiment: the sheet resistance is 45Ω, and the thickness of the adhesive layer is 5 μm.

Embodiment 3

[0035] The conductive adhesive is prepared according to the following composition ratio (mass percentage content):

[0036] Octahydroxyquinoline 3%,

[0037] Graphite 45%,

[0038] Acrylic copolymer 30%,

[0039] Linseed oil 1%,

[0040] Isopropanol 5%,

[0041] KH560 1%,

[0042] Water 15%.

[0043] The preparation method is the same as in Example 1.

[0044] The effect of the embodiment: the sheet resistance is 30, and the thickness of the adhesive layer is 7 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sheet resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com