-70 DEG C lithium ion battery low-temperature electrolyte and preparation method thereof

A lithium-ion battery, electrolyte technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of low oxidative SEI instability of electrolyte, sacrificing battery energy density, power density and safety, etc. Affordable price, easy to implement, guaranteed stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The electrolytic solution of the present embodiment comprises commercial lithium salt and solvent, and commercial lithium salt is the lithium difluorooxalate borate (LiDFOB) that molecular weight is 143.77, and solvent is made up of fluoroethylene carbonate, dimethyl sulfite and isobutyl formate, The volume percentage of fluoroethylene carbonate in the solvent is 20vt%, the volume percentage of dimethyl sulfite is 20vt%, and the volume percentage of isobutyl formate is 60vt%.

[0040] The electrolyte preparation method of the present embodiment is as follows:

[0041] Step 1. Put the commercial lithium salt into the vacuum transition chamber of the glove box. The temperature of the transition chamber is set at 70-90°C, and the drying time is 3-5 days to ensure that the moisture content detected by the moisture detector is lower than 100ppm.

[0042] Step 2, transferring the dried lithium salt obtained in step 1 to a glove box.

[0043] Step 3, will Molecular sieves w...

Embodiment 2

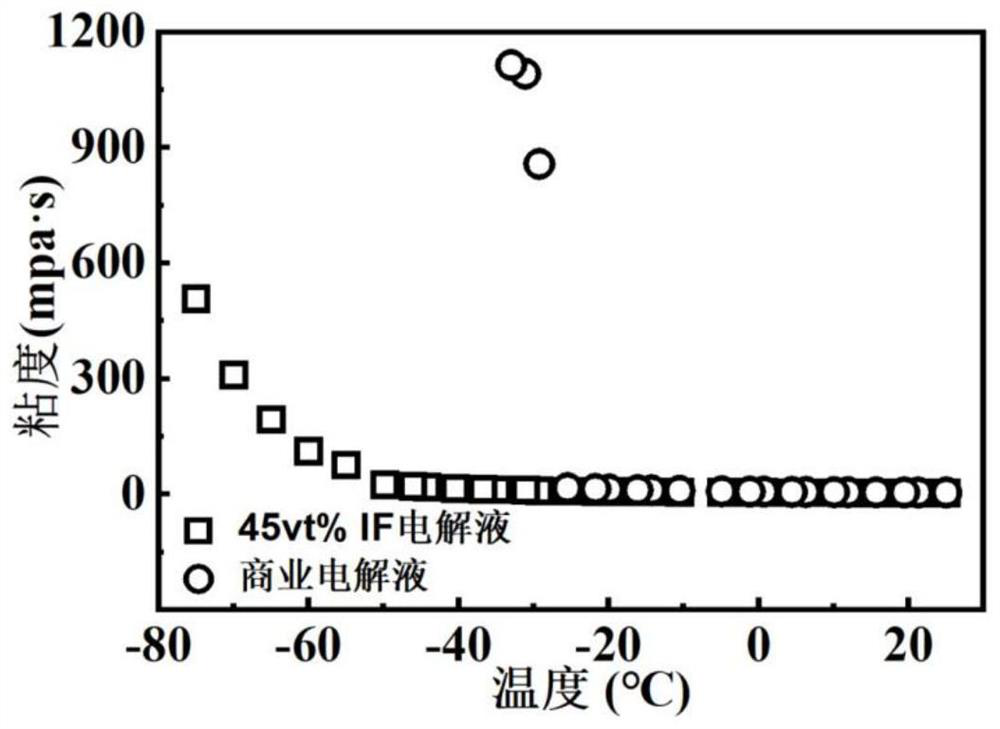

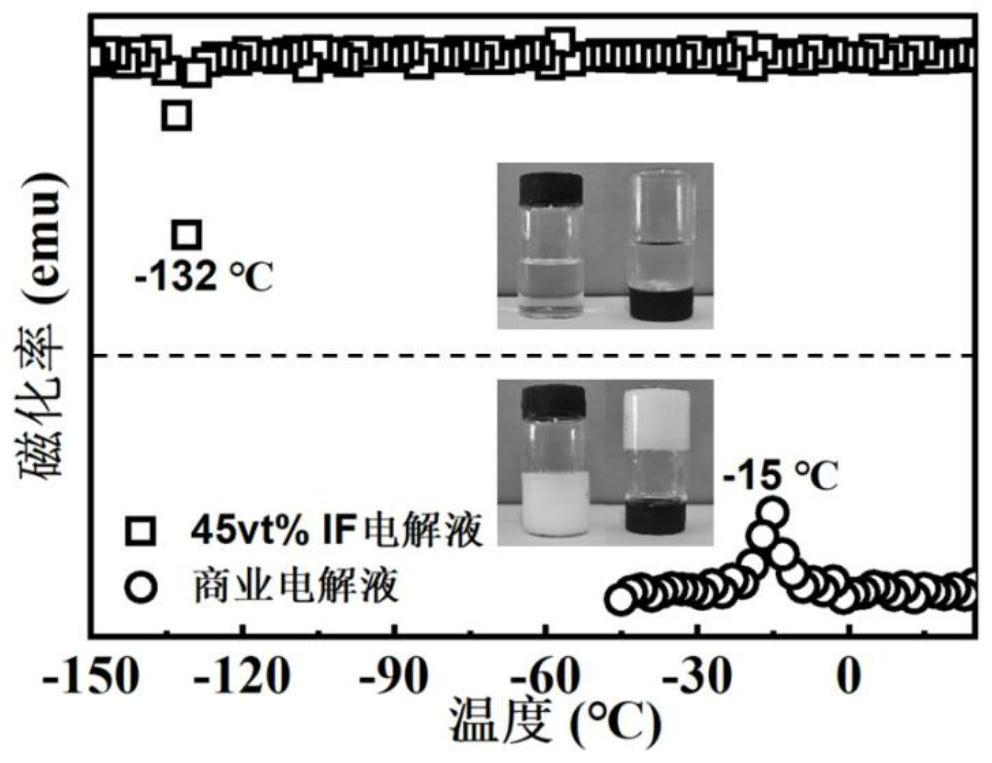

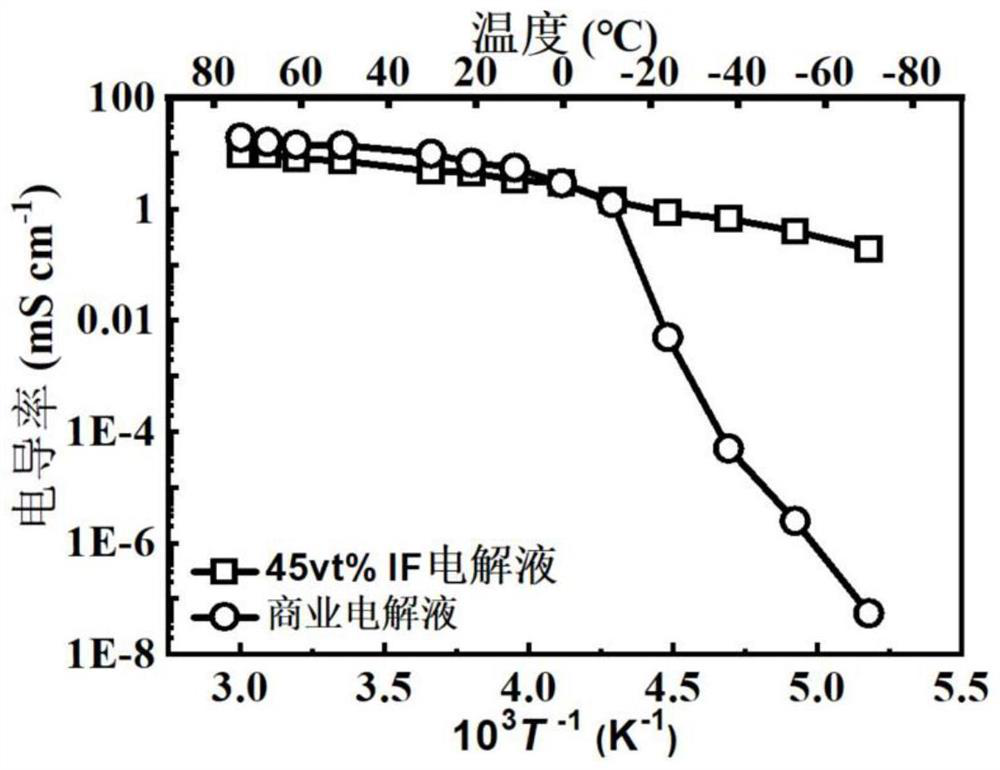

[0047]The difference between this embodiment and Example 1 is: the volume percentage of fluoroethylene carbonate in the solvent is 20vt%, the volume percentage of dimethyl sulfite is 35vt%, the volume percentage of isobutyl formate is 45vt%, and all the other operations The process and parameter settings are the same as in Example 1, and the obtained electrolyte is referred to as 45vt% IF electrolyte for short.

Embodiment 3

[0049] The difference between this embodiment and Example 1 is: the volume percentage of fluoroethylene carbonate in the solvent is 20vt%, the volume percentage of dimethyl sulfite is 40vt%, the volume percentage of isobutyl formate is 40vt%, and all the other operations The process and parameter setting are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com