Functional health maca drink and production method thereof

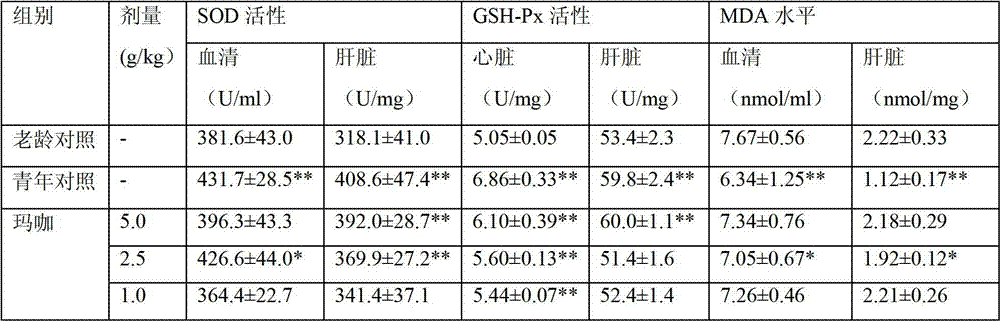

A health-care beverage and functional technology, applied in the field of maca functional health-care beverage and preparation, can solve the problems of damage, long extraction time, incomplete extraction of functional components, etc., and achieve improved sperm quality, improved immunity, and a wide range of drinking populations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

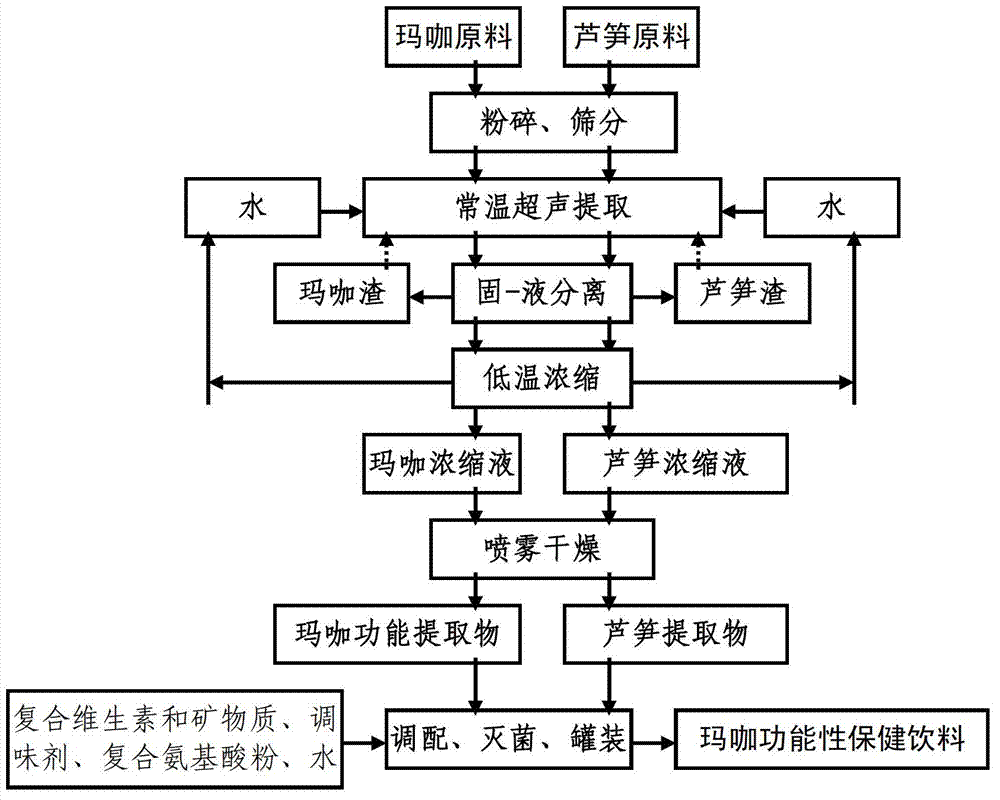

Method used

Image

Examples

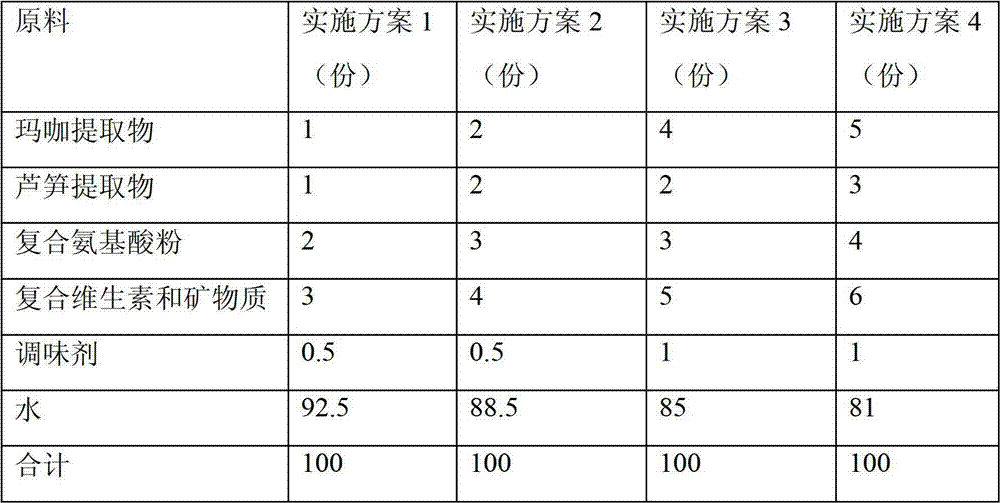

Embodiment 1

[0031] 1. Preparation of maca extract: crush maca dry material to 20 mesh, according to water:material ratio 20:1 (liter:kg), extraction temperature 20°C, ultrasonic power 200W / cm 2 , extraction time 30 minutes, extraction 3 times, solid-liquid separation, supernatant liquid concentrated in vacuo at 60°C, under the condition of air inlet 150°C and outlet air 70°C, the concentrated solution was spray-dried to obtain Maca functional extract;

[0032] 2. Preparation of asparagus extract: Grind asparagus raw materials to 20 mesh, according to water:material ratio 2:1 (liter:kg), extraction temperature 20°C, ultrasonic power 200W / cm 2 , the extraction time is 30 minutes, the extraction is 3 times, solid-liquid separation, the clear liquid is concentrated in vacuum at 60°C, and the concentrated liquid is spray-dried under the conditions of 150°C air inlet and 70°C air outlet to obtain asparagus extract;

[0033] 3. Preparation of compound amino acid powder: Put the hydrolyzed protei...

Embodiment 2

[0035] 1. Preparation of maca extract: crush maca dry material to 40 mesh, according to water:material ratio 25:1 (liter:kg), extraction temperature 40°C, ultrasonic power 250W / cm 2 , the extraction time is 40 minutes, extraction is performed twice, solid-liquid separation, the clear liquid is concentrated in vacuum at 70°C, and the concentrated solution is spray-dried under the conditions of 180°C air inlet and 90°C air outlet to obtain Maca functional extract;

[0036] 2. Preparation of asparagus extract: crush the asparagus raw material to 40 mesh, according to the water:material ratio of 10:1 (liter:kg), the extraction temperature is 40°C, and the ultrasonic power is 250W / cm 2 , extraction time 40 minutes, extraction 2 times, solid-liquid separation, supernatant liquid concentrated in vacuum at 70°C, under the conditions of 170°C inlet air and 80°C outlet air, the concentrated solution was spray-dried to obtain asparagus extract;

[0037] 3. Preparation of compound amino a...

Embodiment 3

[0039] 1. Preparation of maca extract: crush maca dry material to 60 mesh, according to water:material ratio 30:1 (liter:kg), extraction temperature 50°C, ultrasonic power 300W / cm 2 , the extraction time is 60 minutes, extraction once, solid-liquid separation, the clear liquid is vacuum concentrated at 80°C, and the concentrated solution is spray-dried under the conditions of 180°C inlet air and 90°C outlet air to obtain Maca functional extract;

[0040] 2. Preparation of asparagus extract: crush asparagus raw materials to 60 mesh, according to water:material ratio 20:1 (liter:kg), extraction temperature 50°C, ultrasonic power 300W / cm 2 , the extraction time is 60 minutes, extraction once, solid-liquid separation, the supernatant liquid is vacuum concentrated at 80°C, and the concentrated liquid is spray-dried under the conditions of 180°C inlet air and 90°C outlet air to obtain asparagus extract;

[0041] 3. Preparation of compound amino acid powder: Put the hydrolyzed protei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com