TIG (tungsten inert gas) welding method for high-nitrogen steel under double-layer gas flow shielding

A welding method and high-nitrogen steel technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as shallow molten pool depth, overflow of nitrogen elements in weld seams, and increase the depth of high-nitrogen steel TIG welds, etc., to achieve Reduced surface width, less spill effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

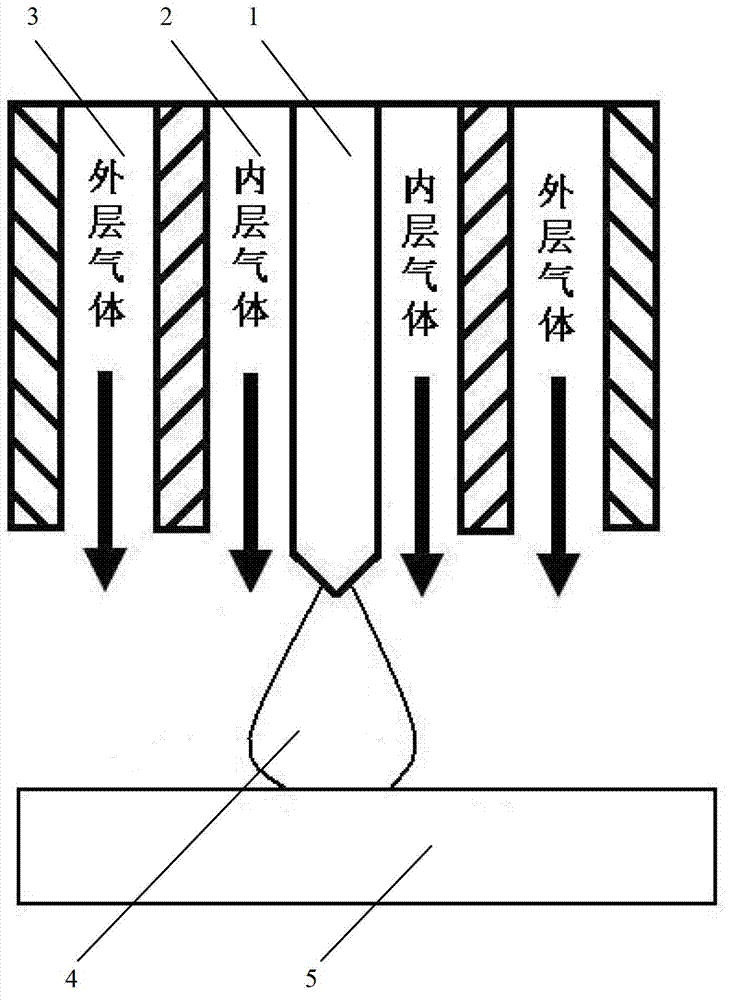

[0026] Such as figure 1 As shown, the double-layer gas flow shielded TIG welding structure of high nitrogen steel of the present invention comprises: electrode 1, inner layer gas channel 2, outer layer gas channel 3, double-layer protective gas channel is set on the outside of electrode 1: inner layer gas channel 2 And the outer layer gas channel 3, through the electrode 1 to generate an arc (welding arc) 4, to perform tungsten inert gas shielded welding on the high nitrogen steel base material 5. It is characterized by the use of double-layer protective gas channels, that is, the inner layer gas is pure inert gas (Ar, He, etc.), and the outer layer gas contains inert gas and trace active gas (O 2 , CO 2 etc.) gas mixture. The present invention uses the inner layer of pure He or Ar gas to generate an arc, and passes through the outer layer of He-O 2 , He-CO 2 , Ar-O 2 or Ar-CO 2 The mixed gas realizes the dissolution transition of the active components to the liquid molt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com