Space tethered unfoldable covered surface system

A space tether and shielding surface technology, applied in the aerospace field, can solve problems such as poor feasibility and high technical difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

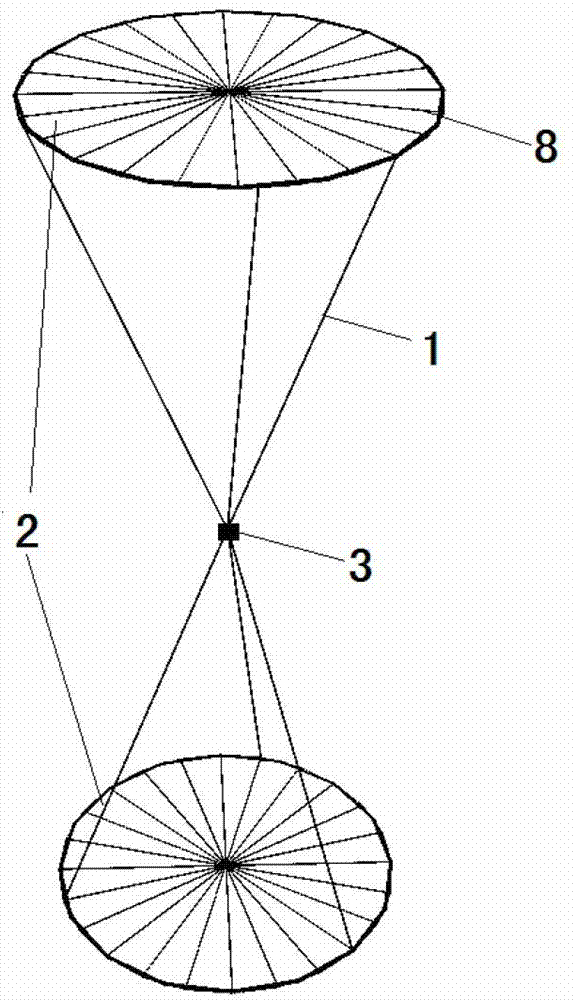

[0042] refer to figure 1 The invention consists of a flexible traction cable 1 , a shielding surface 2 and a traction cable control mechanism 3 . The specific number M of the shielding surface is determined according to the design requirements, and the value range is 2≤M≤18. In this example, two upper and lower shielding surfaces with different expansion diameters are selected. The expansion diameter of the upper shielding surface is 100m, and the expansion diameter of the lower shielding 50m.

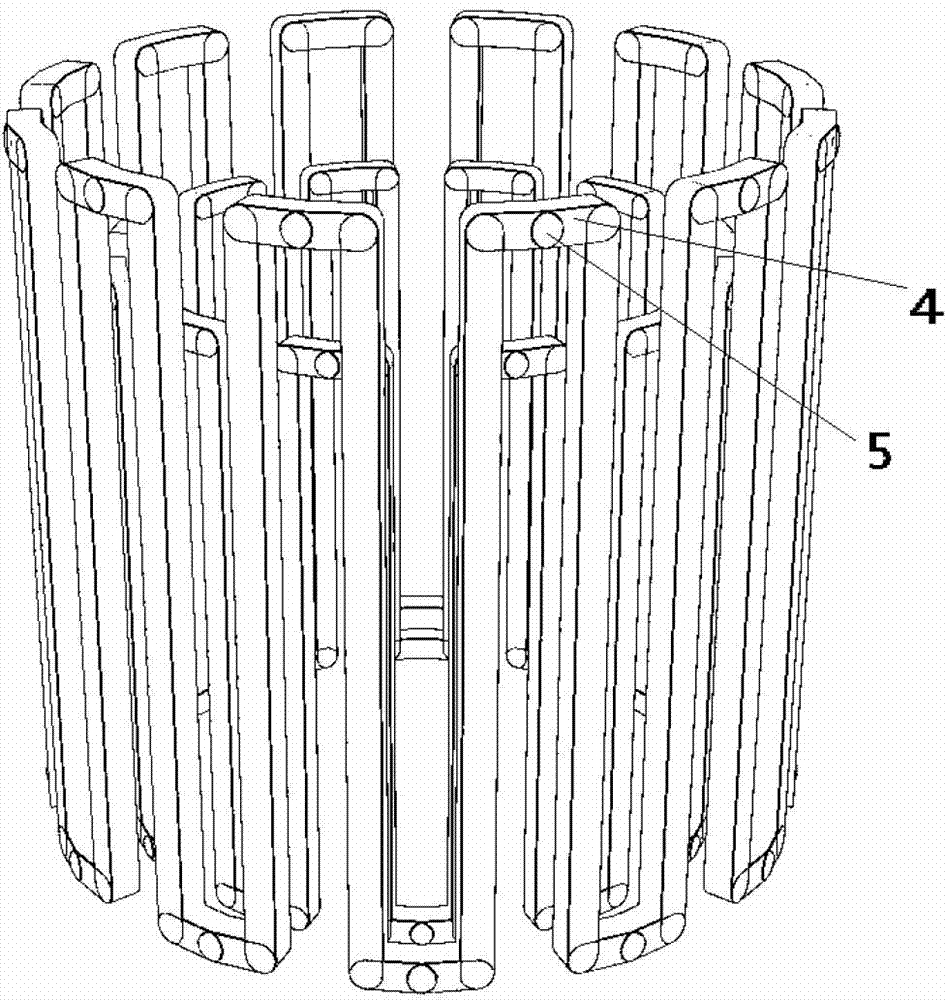

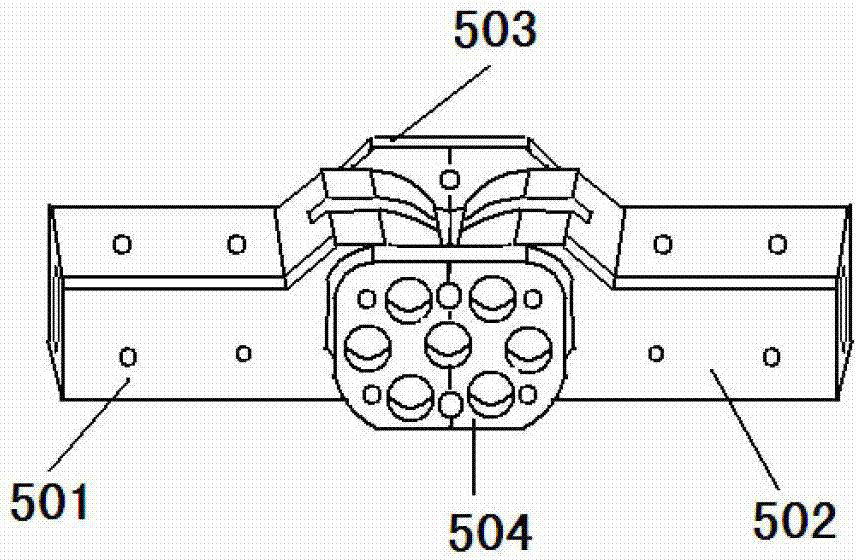

[0043] refer to figure 2 , for each shielding surface 2, the folding ring 4 and the connecting joint 5 are used to form a rigid structure, and the flexible wire mesh 8 is bound to the rigid structure to form the shielding surface 2. There are multiple folding rings 4, the specific number 6X is determined according to the opening diameter of the shielding surface, and the value range is X≥1. In this example, 24 folding rings are used for the upper and lower shielding surfaces, and th...

Embodiment 2

[0050] refer to Figure 8 , the present invention is composed of a flexible traction cable 1, a shielding surface 2 and a traction cable control mechanism 3. The specific number M of the shielding surface is determined according to the design requirements, and the value range is 2≤M≤18. In this example, three shielding surfaces with the same expansion diameter are selected, and the expansion diameter of each shielding surface is 30m.

[0051] refer to Figure 9 , for each shielding surface 2, the folding ring 4 and the connecting joint 5 are used to form a rigid structure, and the flexible wire mesh 8 is bound to the rigid structure to form the shielding surface 2. There are multiple folding rings 4, the specific number 6X is determined according to the opening diameter of the shielding surface, and the value range is X≥1. In this example, 24 folding rings are used for the three shielding surfaces, and there are 72 folding rings in total, that is, X=12 . Every two folding r...

Embodiment 3

[0058] refer to Figure 10 , the present invention consists of a flexible traction cable 1, a shielding surface 2 and a flexible wire mesh 8. The specific number M of the shielding surface is determined according to the design requirements, and the value range is 2≤M≤18. In this example, two shielding surfaces with the same expansion diameter are selected, and the expansion diameter of each shielding surface is 30m.

[0059] refer to Figure 11 , for each shielding surface 2, the folding ring 4 and the connecting joint 5 are used to form a rigid structure, and the flexible wire mesh 8 is bound to the rigid structure to form the shielding surface 2. There are multiple folding rings 4, the specific number 6X is determined according to the opening diameter of the shielding surface, and the value range is X≥1. In this example, 24 folding rings are used for the upper and lower shielding surfaces, and there are 48 folding rings in total, that is, X=8. Every two folding rings 4 are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com