Gearless cable lift with a dual winding-drive block

A gearless, double-winding technology, used in elevators, lifts, transportation and packaging in buildings, can solve the problems of cost, safety hazards, high cost, and achieve the effect of reduced noise level and long working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

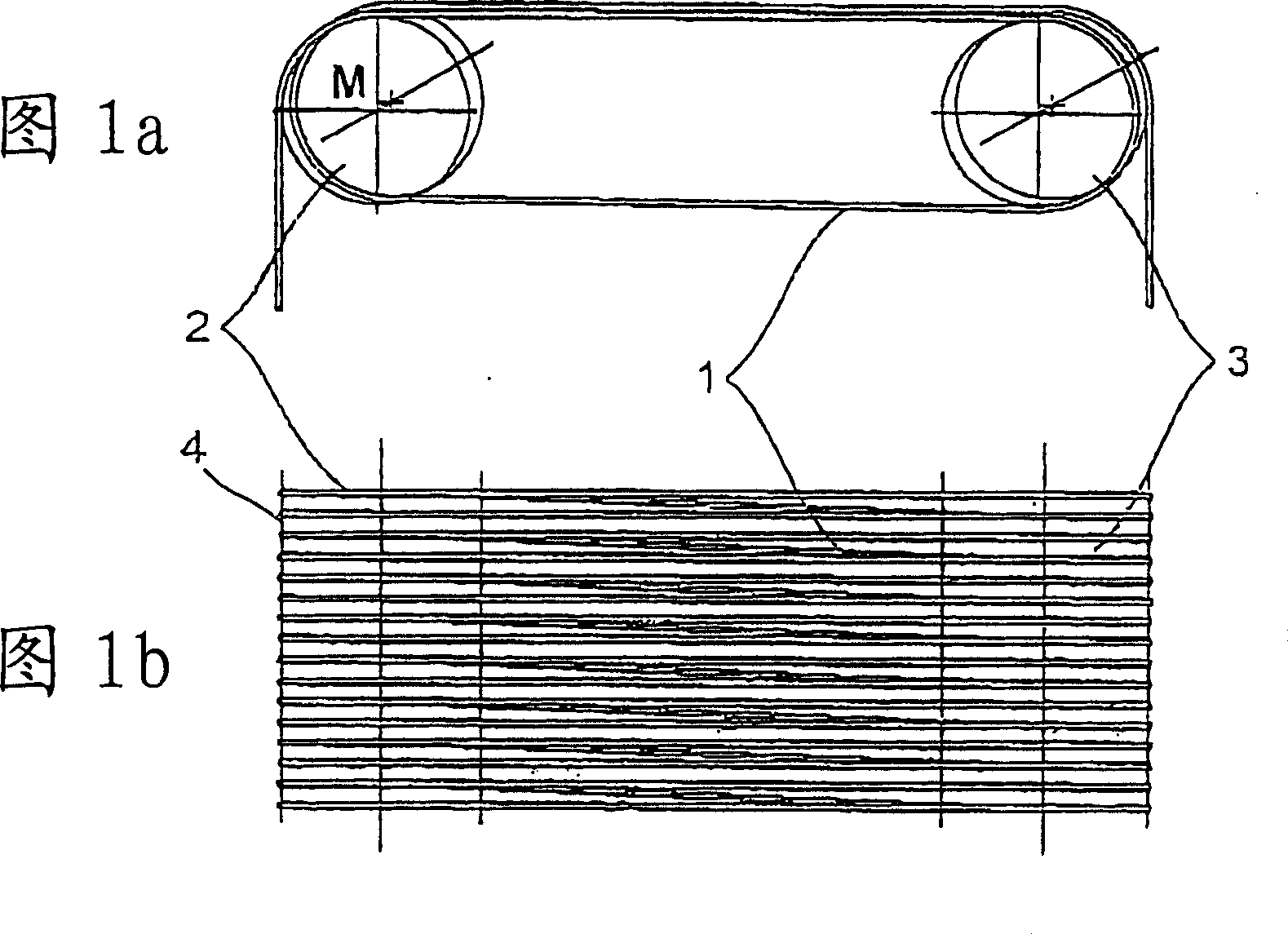

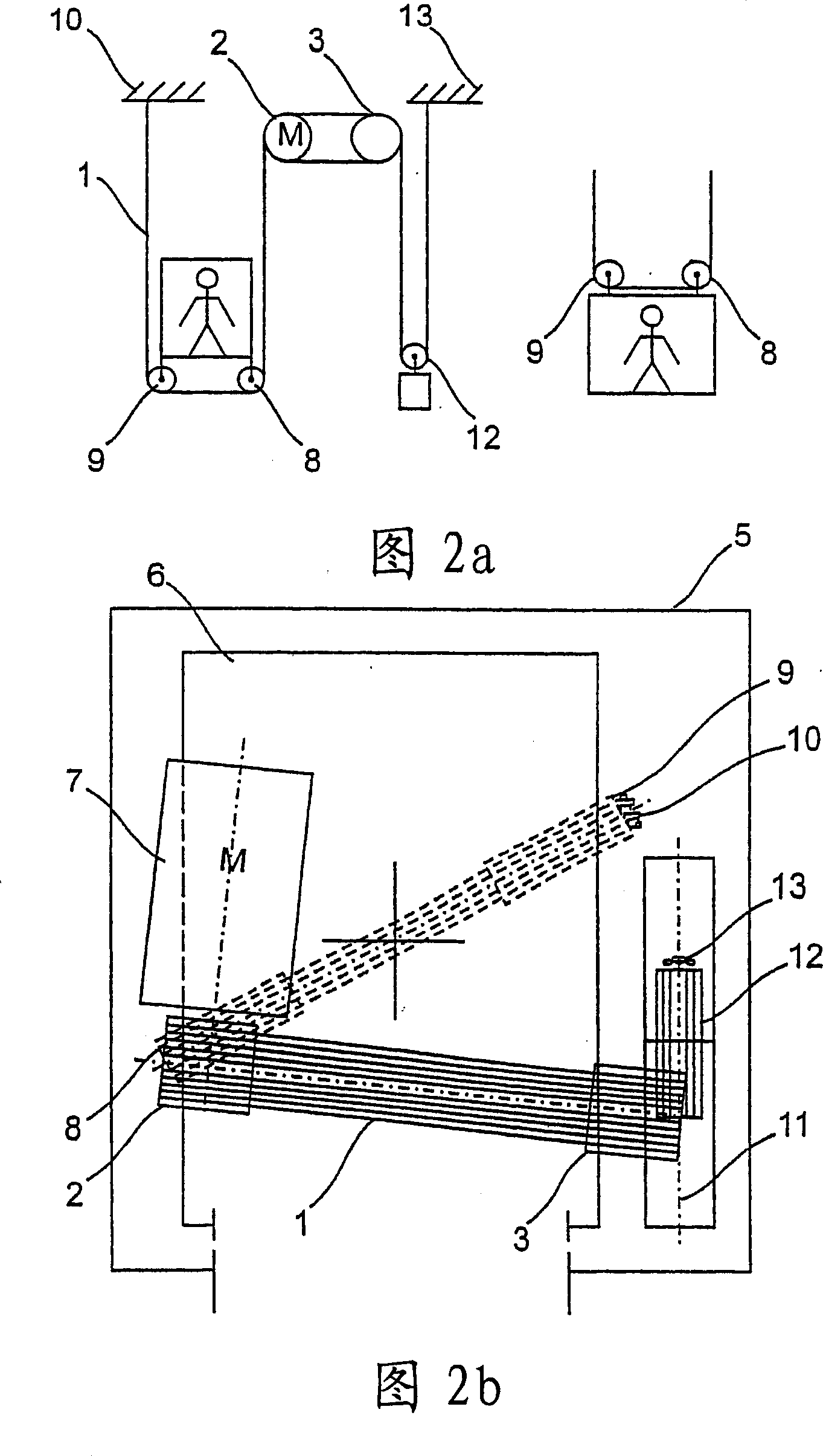

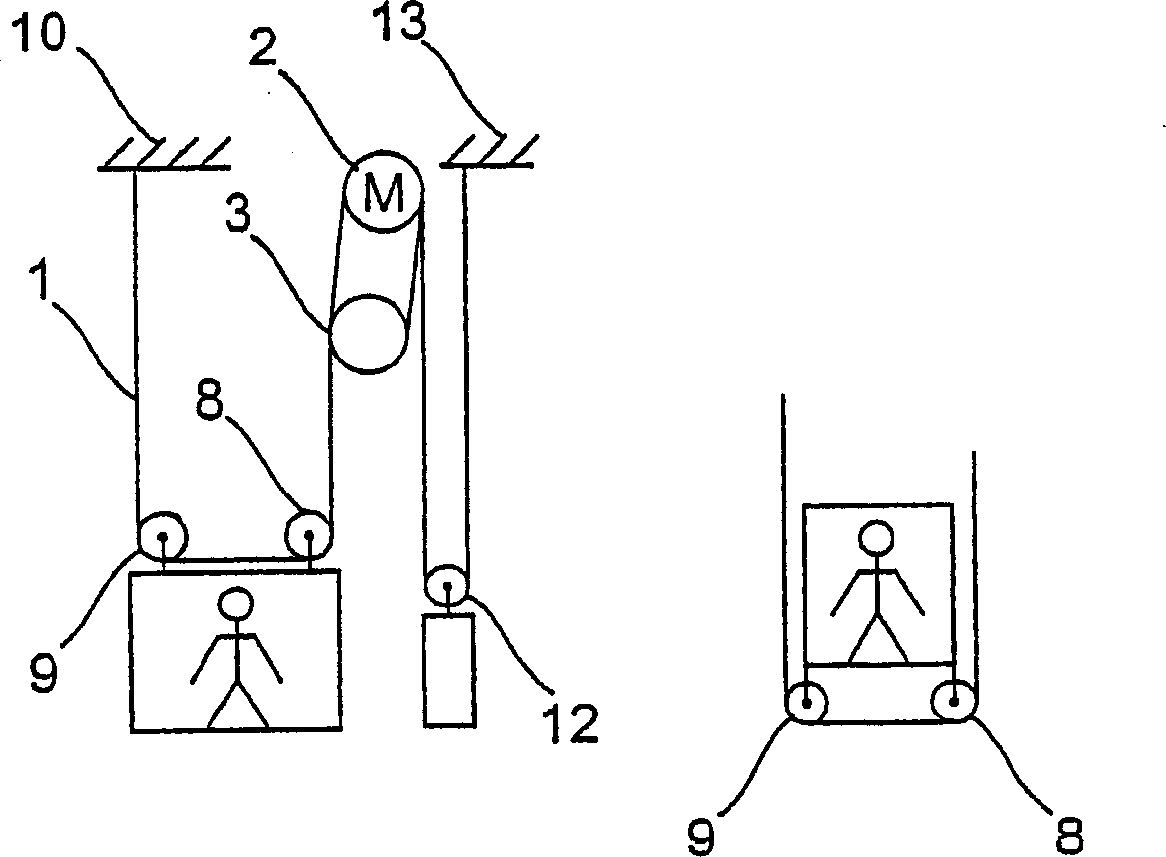

[0025] A known cable-operated drive with double winding is shown in detail in Figures 1a and 1b. A set of load-carrying cables 1 in this embodiment consists of 8 parallel-extending flat load-bearing cables with a nominal diameter of 6 mm. guide, while extending to the secondary pulley also with a nominal diameter of 240 mm, winding the secondary pulley 3, extending back to the drive pulley 2, winding the drive pulley 2, returning to the secondary pulley 3, in the secondary Pulley 3 again guides its downward extension. It is also possible to use a drive pulley with a smaller nominal diameter instead of the drive pulley with a nominal diameter of 240mm. For example, the nominal diameter is only equal to 180 mm, which corresponds to a ratio of 30 between the diameter of the drive pulley and the nominal diameter of the carrying cable.

[0026] Referring to Fig. 1a, only one cable of the eight load-bearing cables of the load-bearing cable set 1 is shown in the figure. The transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com