Method for manufacturing stainless steel negative plate

A manufacturing method and cathode plate technology, which is applied in the direction of electrodes, photographic technology, instruments, etc., can solve the problem of insufficient connection between the cathode plate body and the connecting sleeve, poor corrosion resistance of the cathode plate body, high temperature heating of the conductive rod, etc. problems, to achieve the effect of accelerating the speed of copper adsorption, stable mechanical properties, and avoiding heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below through specific examples.

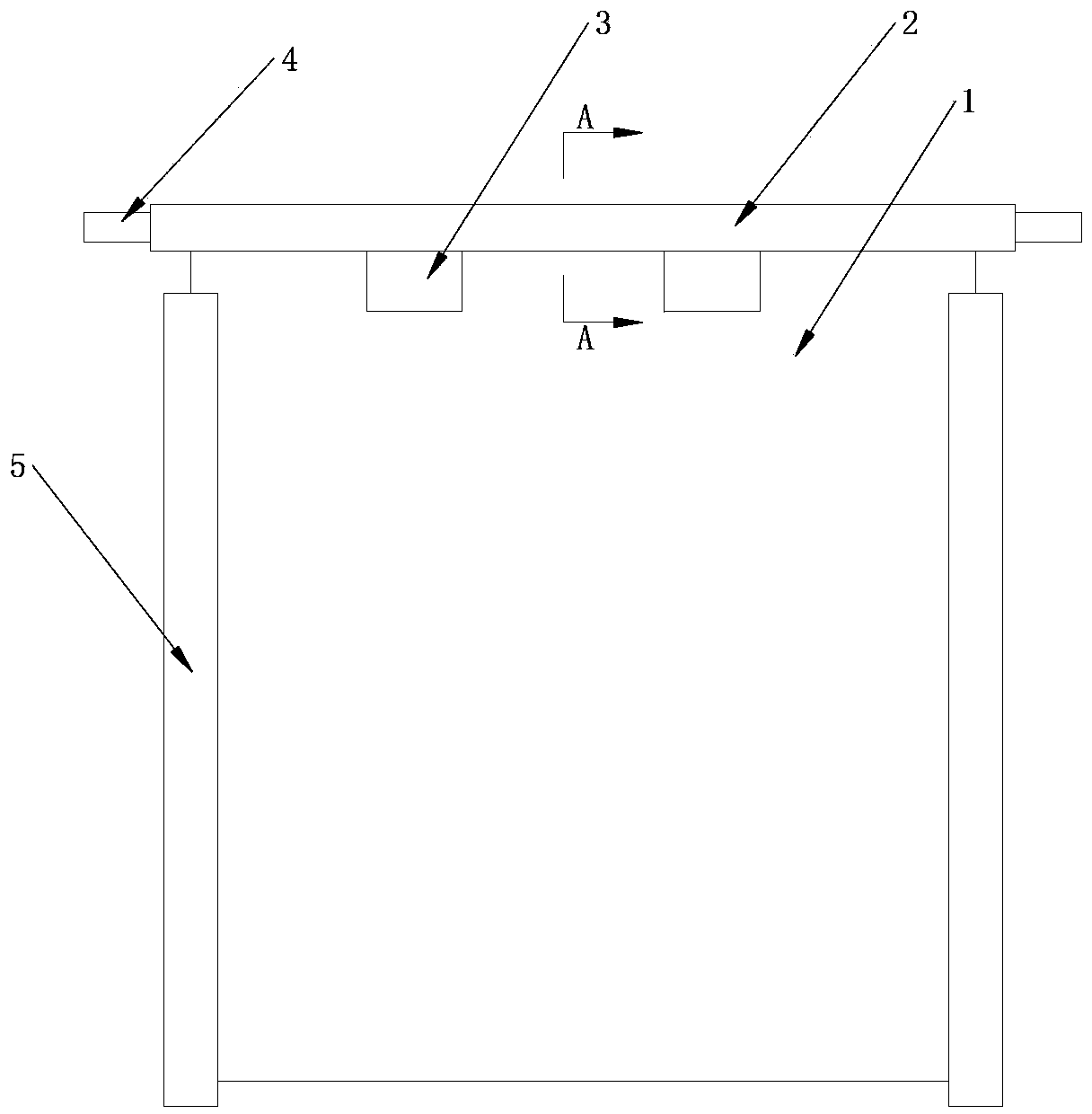

[0030] A method for making a stainless steel cathode plate, such as figure 1 shown, including

[0031] 1) material selection

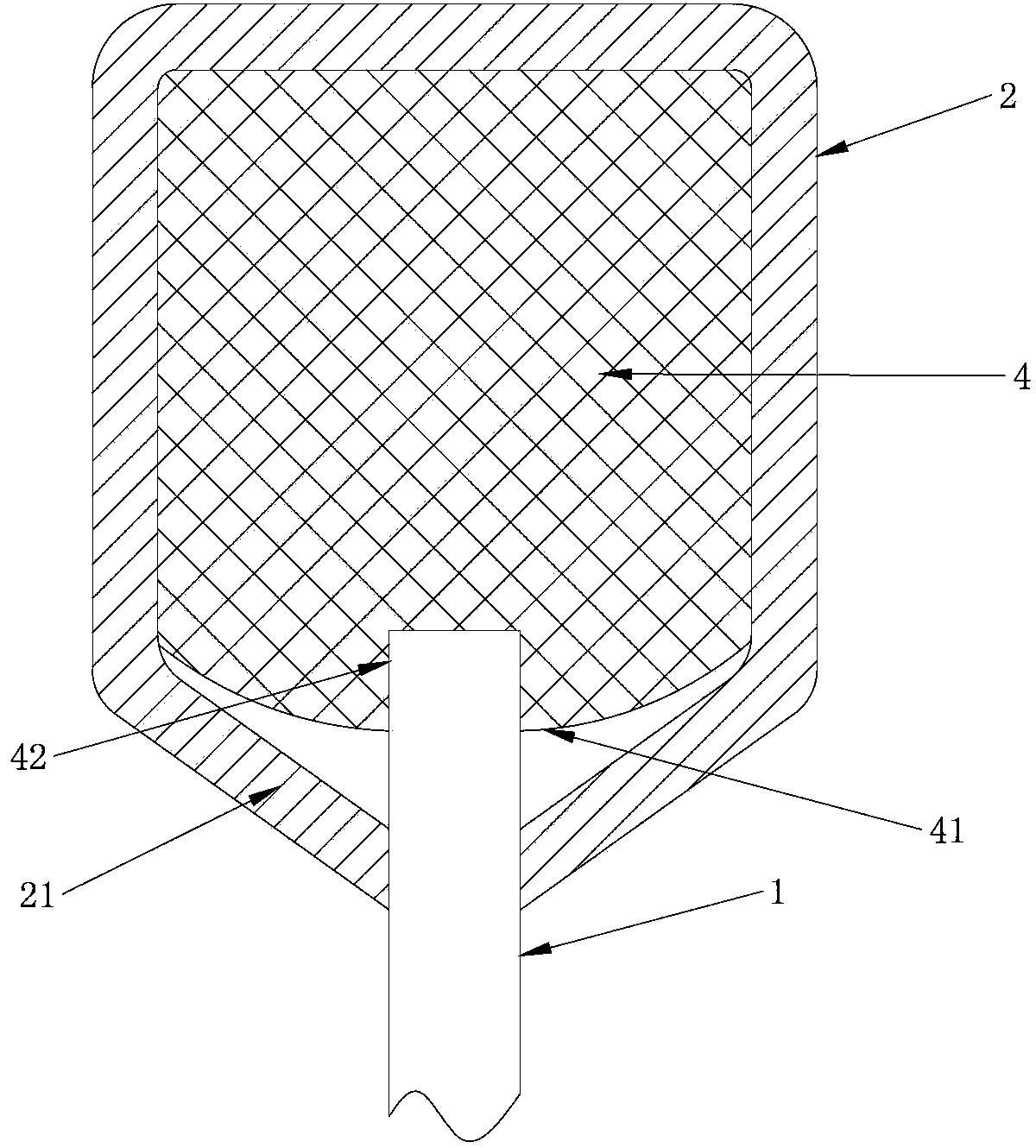

[0032] The cathode plate 1 is made of 316L stainless steel or duplex stainless steel with a surface roughness of 0.16-0.6mm; the conductive rod 4 is made of electrolytic copper with a purity greater than 99%, preferably 99.99% electrolytic copper; the connecting sleeve 2 is made of 316L stainless steel plate; 316L is a variety of stainless steel containing molybdenum, which has strong corrosion resistance, stable mechanical properties, can withstand greater current density, accelerates the adsorption speed of copper ions, and also improves the service life.

[0033] 2) Processing

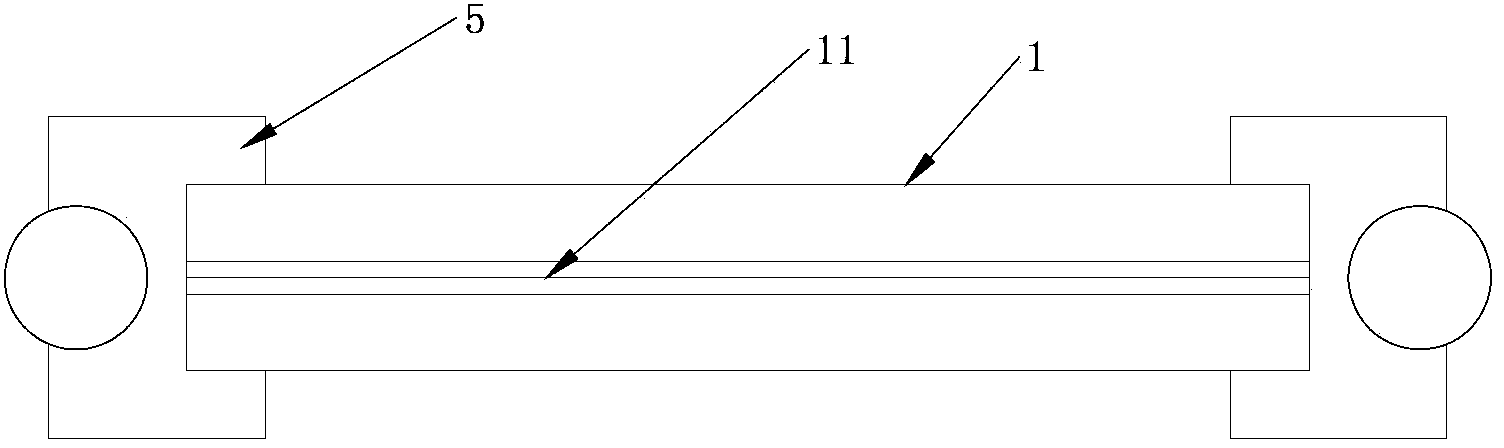

[0034] 2.1. Cut a square or oval hoisting hole 3 on one end of the cathode plate 1 on the cutting device; the length of the cathode plate 1 is 1095 mm, the width is 1047 mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com